Titanium or titanium alloy with surface bioactive layer and preparation method thereof

A bioactive, titanium alloy technology, applied in the direction of surface reaction electrolytic coating, superimposed layer plating, coating, etc., can solve the problems of short production cycle, residual stress, long production cycle, etc., to achieve short production cycle, combined High strength and good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] After degreasing with a 5% NaOH aqueous solution at 70°C, the surface of the Ti-6Al-4V sample was polished with 100#, 400#, and 800# silicon carbide sandpaper, cleaned with distilled water, and ultrasonically cleaned at 15kHz in acetone with a concentration of 99.5%. After washing for 5 minutes, blow dry in the air.

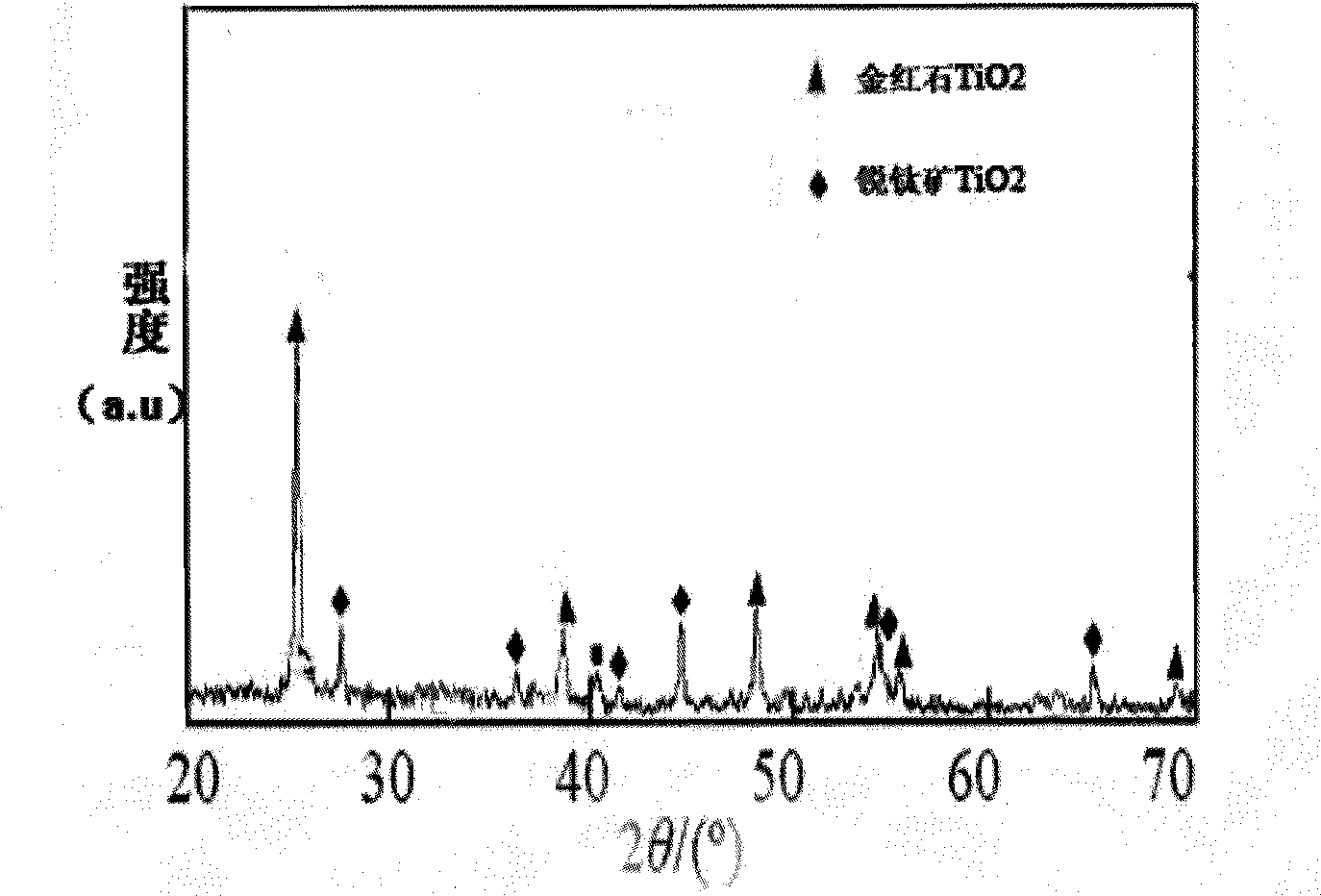

[0047] With stainless steel as the cathode and Ti-6Al-4V sample as the anode, oxidize in 0.1mol / L calcium acetate and 0.02mol / L sodium dilight phosphate solution, the voltage is 200V, the time is 60min, after the above oxidation After treatment, the surface of Ti-6Al-4V sample is porous (see attached figure 1 ), through X-ray phase analysis (see attached figure 2 ), the main component of the ceramic membrane is TiO 2 , The porosity of the membrane was 42% as measured by the pore size distribution.

[0048] The oxidized Ti-6Al-4V sample was subjected to the first hydrothermal synthesis treatment. The solution was deionized water, and the pH value was ad...

Embodiment 2

[0053] After degreasing with 5% NaOH aqueous solution at 80°C, the surface of the Ti-6Al-4V sample was polished with 100#, 400#, and 800# silicon carbide sandpaper respectively, cleaned with distilled water, and ultrasonicated at 20kHz in acetone with a concentration of 99.5%. After cleaning for 7 minutes, blow dry in the air.

[0054] With stainless steel as the cathode and Ti-6Al-4V sample as the anode, oxidize in 0.3mol / L calcium acetate and 0.1mol / L sodium dilight phosphate solution, the voltage is 250V, the time is 40min, after the above oxidation After treatment, the surface of the Ti-6Al-4V sample is porous. According to the energy spectrum and X-ray phase analysis, the main component of the ceramic film is TiO 2 , The porosity of the membrane was 46% as measured by the pore size distribution.

[0055] The oxidized Ti-6Al-4V sample was subjected to the first hydrothermal synthesis treatment. The solution was deionized water, and the pH value was adjusted to 11 with NaO...

Embodiment 3

[0060] After degreasing with a 5% NaOH aqueous solution at 90°C, the surface of the pure titanium sample with a mass fraction of 98.50% was polished with 100#, 400#, and 800# silicon carbide sandpaper, and then washed with distilled water. After 8 minutes of medium 25kHz ultrasonic cleaning, blow dry in the air.

[0061] With stainless steel as the cathode and pure titanium sample as the anode, the electrolyte solution formula is 0.1mol / L calcium acetate plus 0.01mol / L β-sodium glycerophosphate, the voltage range is 280V, the time is 30min, the surface of the pure titanium sample It is porous, and according to energy spectrum and X-ray phase analysis, the main component of the ceramic membrane is TiO 2 , The porosity of the membrane was 49% as measured by the pore size distribution.

[0062] The oxidized pure titanium sample was subjected to the first hydrothermal synthesis treatment. The solution was deionized water, and the pH value was adjusted to 12 with NaOH. The reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com