Electrochemical preparing method for nano ordered hydroxy apatite coating

An ordered hydroxyapatite and electrochemical technology, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems that the ordered structure of nano-artificial bone materials has not been reported, and achieve the effect of improving biocompatibility and biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

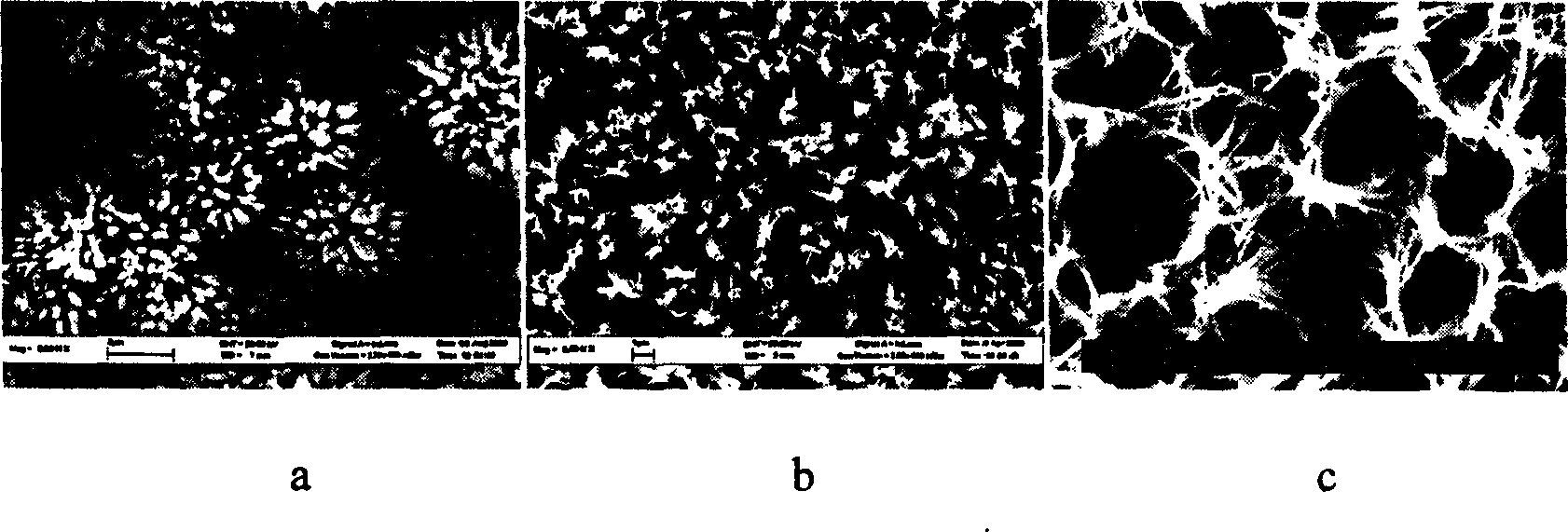

[0017] Embodiment 2: The base material is a pure titanium plate with a thickness of 3 mm, and the surface is mechanically polished to a mirror surface with metallographic sandpaper, cleaned with absolute ethanol and deionized water, and dried for later use; the electrodeposition solution contains 4.2 × 10 -4 mol / LCa(NO 3 ) 2 and 2.5×10 -4 Mole / LNH 4 h 2 PO 4 Electrolyte, using 0.5 mol / LNaNO 3 In order to support the electrolyte, the electrolyte pH=6.00, the control voltage is 3V, the cathodic electrochemical deposition is carried out, the temperature is controlled at 90 ° C, the electrochemical deposition is 1h, and an upright nano-ordered hydroxyapatite deposition layer is obtained on the titanium surface (see figure 1 b), grain size ~100nm.

Embodiment 3

[0018] Embodiment 3: The base material is a pure titanium plate with a thickness of 3mm, and the surface is mechanically polished to a mirror surface with metallographic sandpaper, and cleaned with absolute ethanol and deionized water, and dried for later use; the electrodeposition solution contains 1 × 10 -4 Mole / LCaCl 2 and 0.6×10 -4 Mole / LNaH 2 PO 4 The electrolyte solution, using 0.1 mol / L NaCl as the supporting electrolyte. Electrolyte pH=7.20, control current density to 1mA / cm 2 , carry out cathodic electrochemical deposition, control temperature 100 ℃, electrochemical deposition 1h, obtain microporous nano-ordered hydroxyapatite deposition layer on titanium surface (see figure 1 c), grain size ~60nm.

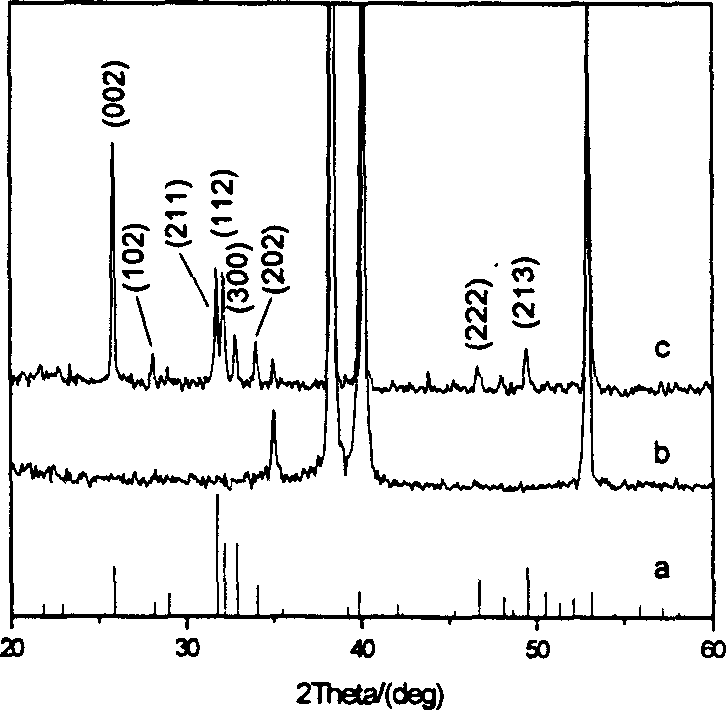

[0019] Depend on figure 1 It can be seen that the basic structural unit of the electrochemically deposited calcium phosphate film layer is generally acicular crystals, and its grain size varies with the preparation conditions. It can be a larger partial columnar cry...

Embodiment 8

[0021] Example 8: The substrate material is a single crystal silicon wafer sprayed with 500nm titanium, cleaned with absolute ethanol and deionized water, and dried for later use; the electrodeposition solution contains 2.5×10 -4 M Ca(NO 3 ) 2 and 1.5×10 -4 N H 4 h 2 PO 4 Electrolyte, electrolyte pH = 7.0, control current density 5mA cm -2 , for cathodic electrochemical deposition. The temperature was controlled at 70° C., and the electrochemical deposition was performed for 1 h to obtain a nano-ordered hydroxyapatite deposition layer on the titanium surface. Coatings were prepared for in vitro cell culture experiments.

[0022] MG63 human osteosarcoma cells were used for the in vitro cell culture test, and RPMI1640 medium (containing 15% fetal bovine serum, penicillin 100U / ml, streptomycin 100 μg / ml) was used for cell culture in a carbon dioxide incubator (5% CO 2 , 37°C, saturated humidity). The cells were inoculated on the material, cultured in the incubator for two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com