Mg-Zn-Sr alloy biomaterial of hydroxyapatite coating and preparation method thereof

A technology of hydroxyapatite and mg-zn-sr, which is applied in the field of materials to achieve high specific strength and specific stiffness, good compatibility and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

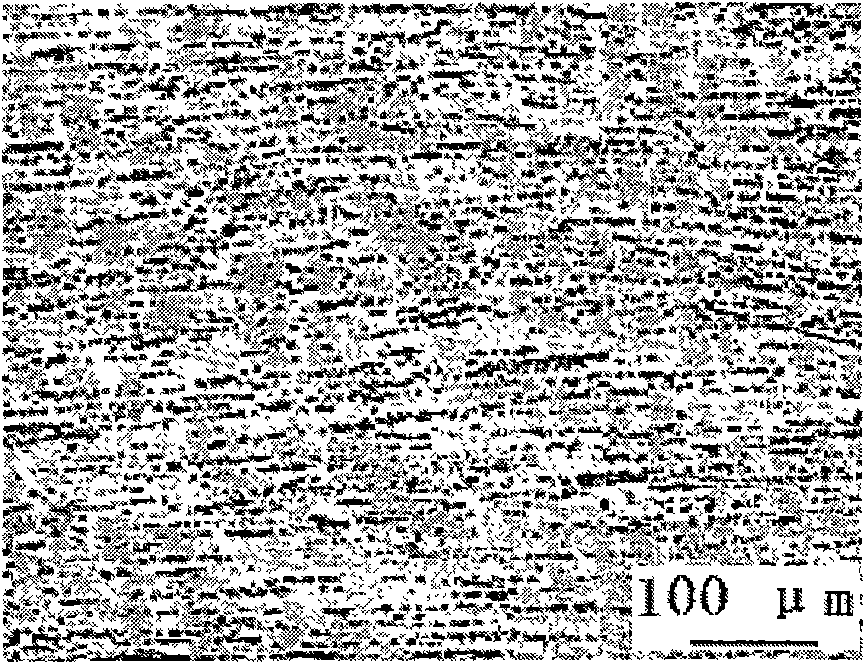

[0024] The magnesium alloy is smelted, cast into an ingot and then rolled. The rolling method is as follows: the ingot is subjected to preliminary rolling under the condition of 380±10℃, the rolling speed is 18m / min, and the total reduction is 10%; Perform intermediate rolling at 10°C with a rolling speed of 14m / min and a total reduction of 5%; and then perform final rolling at 320±10°C with a rolling speed of 8m / min and a total reduction of 2 %; to obtain a magnesium alloy base plate, the composition of which is Zn2%, Sr0.5% by weight, and the balance is magnesium. The mechanical properties of the magnesium alloy base plate are: elastic modulus 35Gpa, tensile strength 300MPa, elongation 15%, hardness 65HV; metallographic photos such as figure 1 shown.

[0025] The magnesium alloy base plate was placed in a 0.2mol / L sodium hydroxide solution and heat-treated at 80±2°C for 115min.

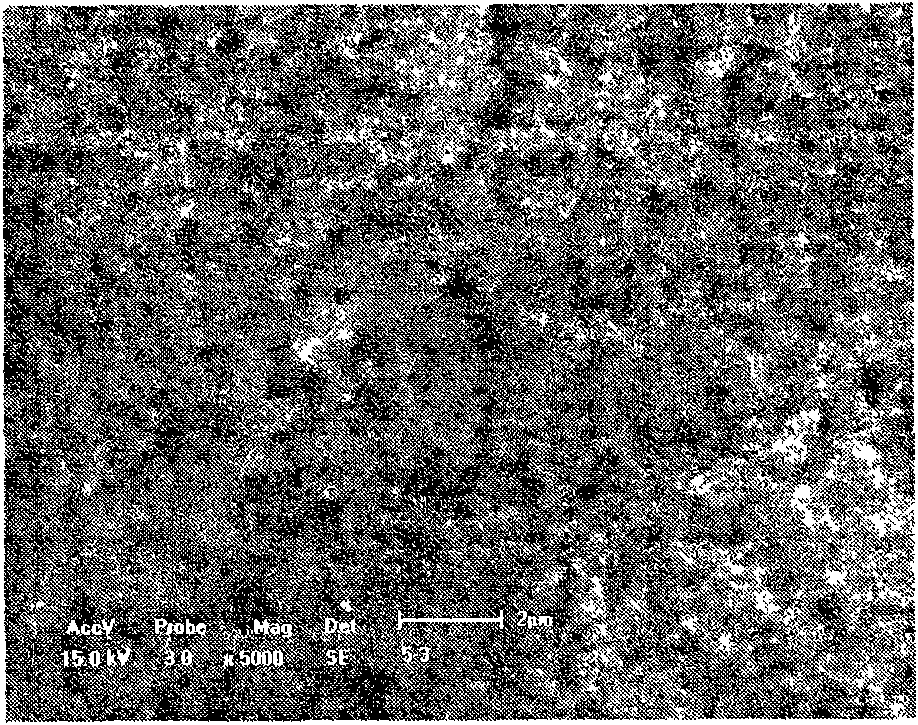

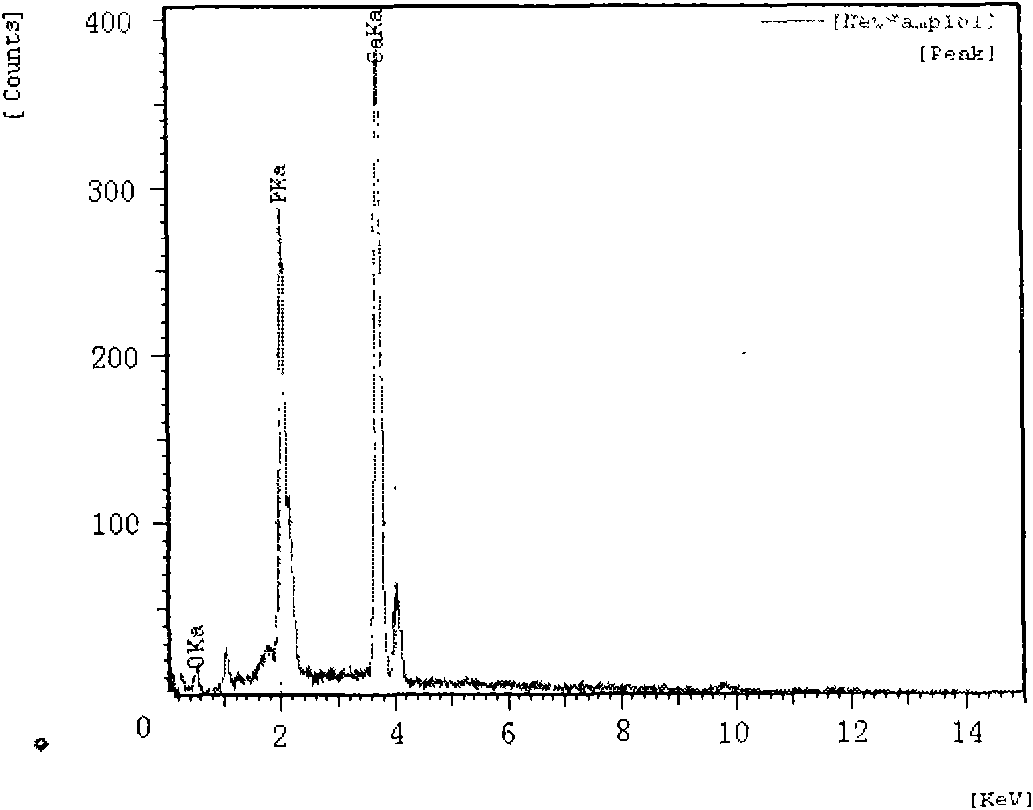

[0026] The heat-treated magnesium alloy base plate was placed in a 2+ and H 2 PO 4 - In th...

Embodiment 2

[0028] The magnesium alloy is smelted, cast into an ingot and then rolled. The rolling method is as follows: the ingot is subjected to preliminary rolling under the condition of 380±10°C, the rolling speed is 20m / min, and the total reduction is 15%; The intermediate rolling is carried out at 10°C, the rolling speed is 15m / min, and the total reduction is 10%; then the final rolling is carried out at 320±10°C, the rolling speed is 10m / min, and the total reduction is 3 %; to obtain a magnesium alloy base plate, the composition of which is Zn3%, Sr1% by weight, and the balance is magnesium. The mechanical properties of the magnesium alloy base plate are as follows: the elastic modulus is 40Gpa, the tensile strength is 305MPa, the elongation is 16%, and the hardness is 60HV.

[0029] The magnesium alloy base plate was placed in a 0.4vmol / L sodium hydroxide solution and heat-treated at 80±2℃ for 120min.

[0030] The heat-treated magnesium alloy base plate was placed in a 2+ and H ...

Embodiment 3

[0032] The magnesium alloy is smelted, cast into an ingot and then rolled. The rolling method is as follows: the ingot is subjected to preliminary rolling under the condition of 380±10°C, the rolling speed is 22m / min, and the total reduction is 20%; Perform intermediate rolling at 10°C, rolling speed is 16m / min, and total reduction is 15%; then finish rolling at 320±10°C, rolling speed is 12m / min, total reduction is 4 %; to obtain a magnesium alloy base plate, the composition of which is Zn4%, Sr1.5% by weight, and the balance is magnesium. The mechanical properties of the magnesium alloy base plate are as follows: the elastic modulus is 45Gpa, the tensile strength is 310MPa, the elongation is 17%, and the hardness is 63HV.

[0033] The magnesium alloy base plate was placed in a 0.6mol / L sodium hydroxide solution and heat-treated at 80±2°C for 125min.

[0034] The heat-treated magnesium alloy base plate was placed in a 2+ and H 2 PO 4 - In the solution, the molar ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com