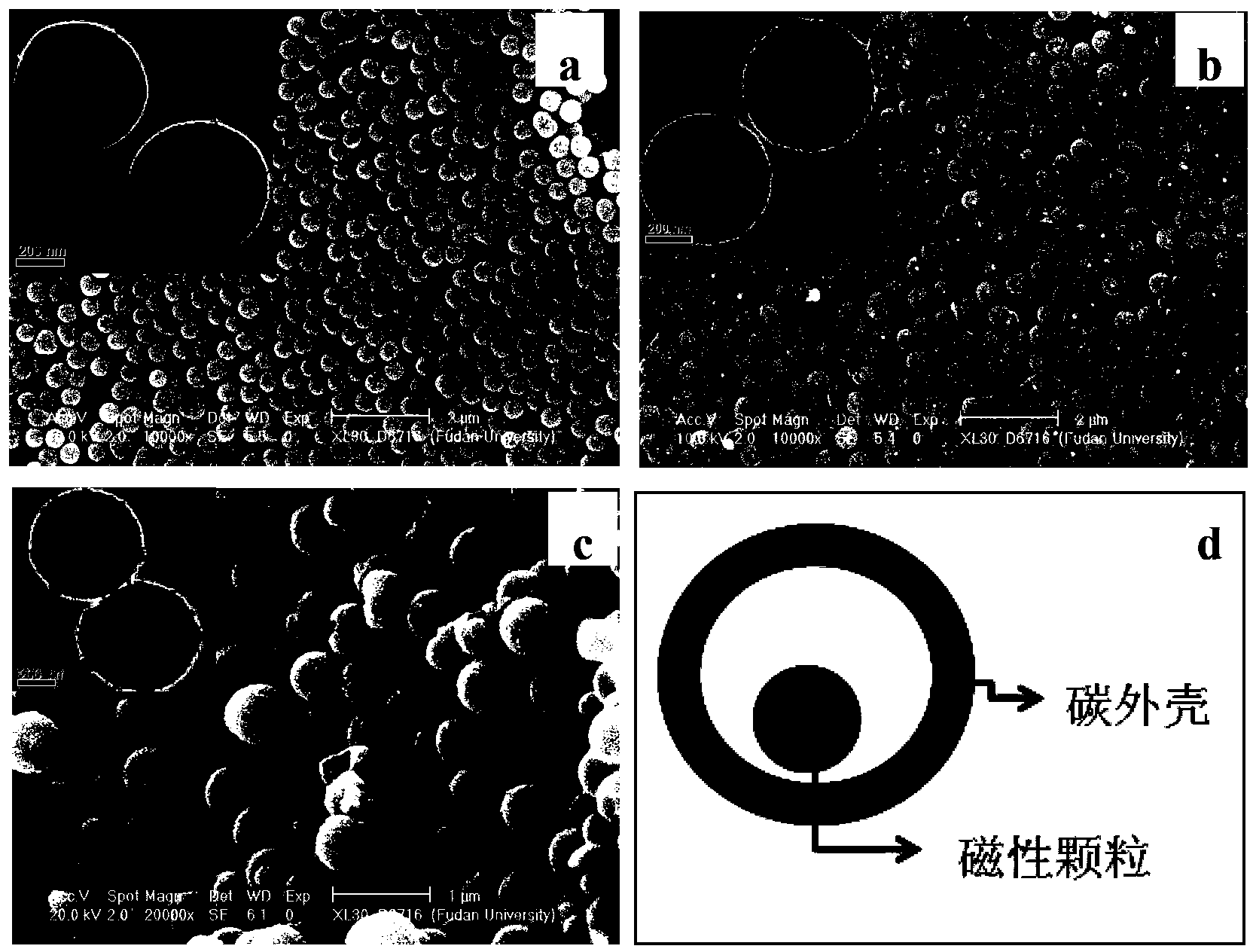

Magnetic polymer/carbon-based microsphere material with core-shell structure and preparation method thereof

A technology of core-shell structure and carbon-based microspheres, which is applied in the direction of magnetic materials, microsphere preparation, magnetic objects, etc., can solve the problems of difficult separation and recycling, difficulty in controlling the thickness of the shell layer, and cumbersome preparation steps, etc. Easy control of layer thickness, strong magnetic response, simple and rapid method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 0.1g magnetic Fe with a particle size of 250nm 3 o 4 Ultrasonic dispersion of nanoparticles into 40ml ethanol and water mixed solvent (ethanol: water = 2:1), then add concentrated ammonia water (1.25ml, 28wt%), mechanically stir at room temperature for 10min, add 0.2g resorcinol, stir for 10min , add 0.28ml formaldehyde solution. Continue to stir for 2h, separate it from the solution by a magnet, wash it repeatedly with ethanol and distilled water successively, and dry at room temperature to obtain magnetic phenolic resin microspheres; place the microspheres in nitrogen to roast at a heating rate of 1°C / min, Rise to 600 ° C, and obtain core-shell magnetic carbon spheres after roasting for 5 h.

Embodiment 2

[0027] 0.15g of magnetic nanoparticles γ-Fe with a particle size of 50nm 2 o 3Ultrasonic dispersion into 50ml ethanol and water mixed solvent (ethanol: water = 1:1), then add NaOH (0.5ml, 1M), mechanically stir at room temperature for 10min, add 0.2g resorcinol, stir for 10min, add 0.02g Hexamethylenetetramine, continue to stir for 4h, separate it from the solution by a magnet, wash it repeatedly with ethanol and distilled water, and dry at room temperature to obtain magnetic phenolic resin microspheres, place the microspheres in nitrogen to roast, and heat up The rate was 1°C / min, raised to 600°C, and the core-shell magnetic carbon spheres were obtained after roasting for 5h.

Embodiment 3

[0029] 0.18g magnetic NiFe with a particle size of 340nm 2 o 4 Ultrasonic dispersion of nanoparticles into 35ml ethanol and water mixed solvent (ethanol: water = 2:1), then add KOH (0.2ml, 2M), mechanically stir at room temperature for 10min, add 0.2g melamine, after stirring for 10min, add 0.28 ml formaldehyde, continue to stir for 10 minutes, add 0.5ml of F127 solution (6.4wt%), continue to stir for 4 hours, separate it from the solution by a magnet, wash repeatedly with ethanol and distilled water, and dry at room temperature to obtain magnetic melamine resin microspheres, The microspheres were roasted in nitrogen at a heating rate of 1 °C / min to 600 °C, and core-shell magnetic carbon spheres were obtained after roasting for 5 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com