Method for preparing durable hydrophilic polyether modified amino polysiloxane soft agent

A technology of aminopolysiloxane and aminosilane coupling agent, which is applied in the field of preparation of durable hydrophilic polyether modified aminopolysiloxane softener, can solve the problem of limited improvement of silicone oil softness, easy gelation, Affect the hand feeling and other problems, to achieve the effect of increasing the wearing performance, improving softness and smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

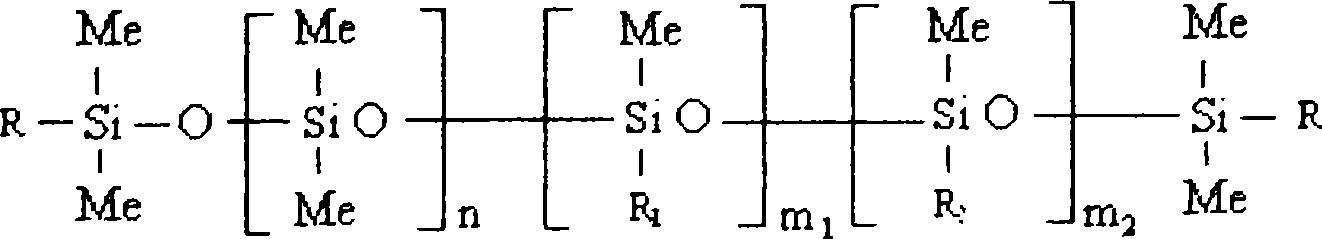

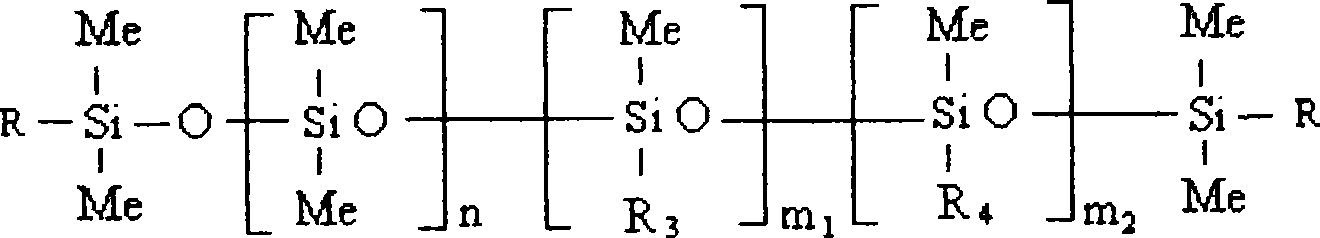

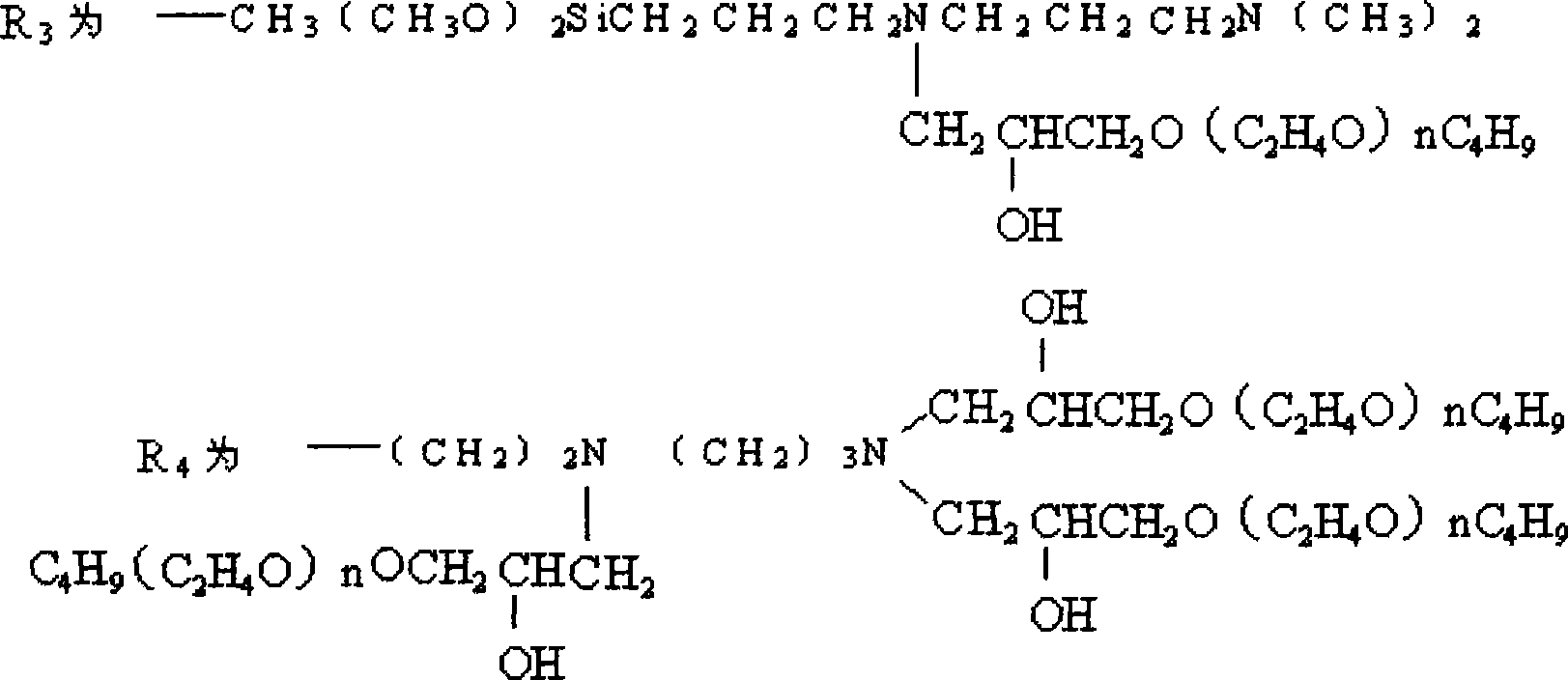

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of a durable hydrophilic polyether-modified aminopolysiloxane softener, comprising the following steps: (1) firstly prepare an aminosilane coupling agent hydrolyzate, put in the aminosilane coupling agent, and slowly Add excess deionized water dropwise, after dropping, stir at a constant temperature of 70°C for 3 hours, then add toluene, azeotropically dehydrate, and steam the toluene to obtain high-viscosity aminosilane coupling agent hydrolyzate; Cyclotetrasiloxane and aminosilane coupling agent hydrolyzate are used as raw materials, and the bulk polymerization method is adopted, and the temperature is raised to 100°C under the condition of basic catalyst and magnetic stirring, and the reaction is carried out for 20 hours, and the ring-opening polymerization produces amino polyorganosilicon with high ammonia value Oxane softener, the catalyst adopts (CH 3 ) 4 NOH, the amount used is to add 10mg (CH 3 ) 4 NOH. After reaching equilibrium, use a ...

Embodiment 2

[0046] A preparation method of a durable hydrophilic polyether-modified aminopolysiloxane softener, comprising the following steps: (1) firstly prepare an aminosilane coupling agent hydrolyzate, put in the aminosilane coupling agent, and slowly Drop in excess deionized water, after the drop, stir at a constant temperature of 90°C for 3 hours, then add toluene, azeotropically dehydrate, and steam the toluene to obtain a high-viscosity aminosilane coupling agent hydrolyzate; Cyclotetrasiloxane and aminosilane coupling agent hydrolyzate are used as raw materials, using bulk polymerization method, heating up to 160°C under alkaline catalyst and magnetic stirring, reacting for 2 hours, and ring-opening polymerization to form amino polyorganosilicon with high ammonia value Oxane softening agent, the catalyst uses NaOH, and the amount used is to add 100 mg of catalyst NaOH to 1 g of octamethylcyclotetrasiloxane. After reaching equilibrium, use a vacuum pump to pump out the unreacted ...

Embodiment 3

[0048] A preparation method of a durable hydrophilic polyether-modified aminopolysiloxane softener, comprising the following steps: (1) firstly prepare an aminosilane coupling agent hydrolyzate, put in the aminosilane coupling agent, and slowly Drop in excess deionized water, after the drop, stir at a constant temperature of 85°C for 3 hours, then add toluene, azeotropically dehydrate, and steam the toluene to obtain a high-viscosity aminosilane coupling agent hydrolyzate; Cyclotetrasiloxane and aminosilane coupling agent hydrolyzate are used as raw materials, and the bulk polymerization method is adopted, and the temperature is raised to 120°C under basic catalyst and magnetic stirring, and the reaction is carried out for 10 hours. The catalyst adopts (CH 3 ) 4 NOH, the amount used is to add 45mg (CH 3 ) 4 NOH, ring-opening polymerization to generate amino polyorganosiloxane softener with high ammonia value. After reaching equilibrium, use a vacuum pump to pump out the unr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com