Lithium ion battery cathode and lithium ion battery

A lithium-ion battery and negative electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of poor rate performance, reduced cycle life, loose negative electrode active material layer, etc., and achieve a low expansion rate. , the effect of reducing the expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

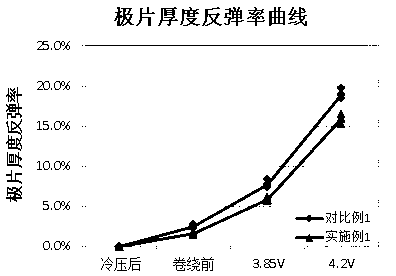

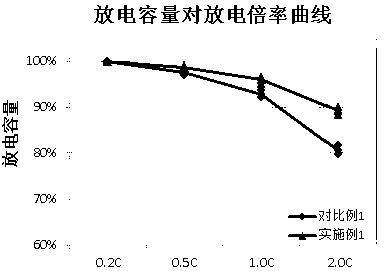

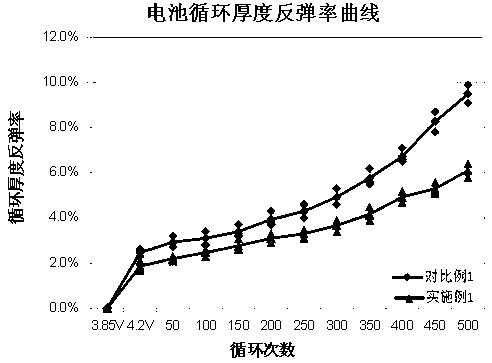

[0034] Example 1, A lithium ion battery negative electrode, comprising a negative electrode current collector and a negative electrode active material layer coated on the negative electrode current collector, the negative electrode active material layer includes a negative electrode active material, a conductive agent, a polymer thickener, and an aqueous emulsion polymer binder and a water-soluble polymer binder, the water-soluble polymer binder is polyethyleneimine, and the weight ratio of the water-emulsion polymer binder to the water-soluble polymer binder is 10:90~90:10 .

[0035] Preparation of the negative electrode: The negative electrode slurry formula is calculated by weight percentage of the dry material, consisting of 2% styrene-butadiene rubber emulsion, 1.5% polyethyleneimine, 0.5% sodium carboxymethyl cellulose, 1% conductive carbon black, and 95% negative electrode active material Composed of five parts, the negative electrode active material is made of artifi...

Embodiment 2

[0047] Example 2, The difference from Example 1 is that the preparation process of the negative electrode of this embodiment is that the negative electrode slurry formula is calculated by weight percentage of dry material, consisting of 2% nitrile rubber emulsion, 1.5% butadiene rubber emulsion, 2% polyethyleneimine , 0.5% carboxymethyl cellulose, 1% carbon fiber, and 93% negative electrode active material. The negative electrode active material is made of natural graphite and graphitized carbon fiber. The weight average molecular weight of polyethyleneimine is about 100,000g / mol. The pH value of the aqueous solution with a mass concentration of 5% is in the range of 9-12, the degree of substitution of carboxymethyl cellulose is in the range of 0.8-1.0, and the viscosity of an aqueous solution with a mass concentration of 1% at 25°C is 1000 -3000mPa.s range. During the slurry preparation process, the solvent is deionized water, and water accounts for 60% of the total slurry ...

Embodiment 3

[0051] Example 3, The difference from Example 2 is that the preparation process of the negative electrode in this example is as follows: the negative electrode slurry formula is calculated by weight percentage of dry material, consisting of 2% butadiene rubber emulsion, 2% polyethyleneimine, 1% hydroxyethyl fiber It consists of five parts: element, 1% carbon nanotubes, and 94% negative electrode active material. The negative electrode active material uses graphitized mesophase carbon microbeads and amorphous carbon. The weight average molecular weight of polyethyleneimine is about 5,000 g / mol. The pH value of the aqueous solution with a mass concentration of 5% is in the range of 9 to 12, the degree of substitution of hydroxyethyl cellulose is in the range of 0.8-1.0, and the viscosity of an aqueous solution with a mass concentration of 1% at 25°C is 1000 -3000mPa.s range. During the slurry preparation process, the solvent is deionized water, and water accounts for 60% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com