Conductive polymer-coated silicon-based negative electrode material and preparation method thereof

A technology of silicon-based negative electrode materials and conductive polymers, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of silicon negative electrode materials such as huge volume expansion and poor conductivity, and achieve good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

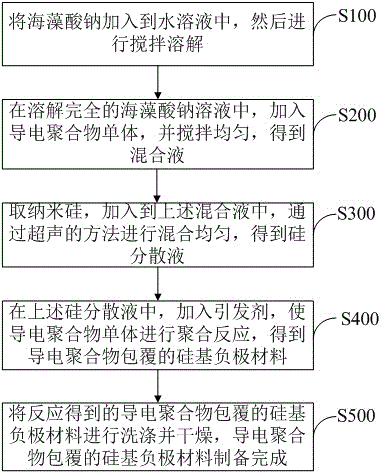

Method used

Image

Examples

Embodiment 1

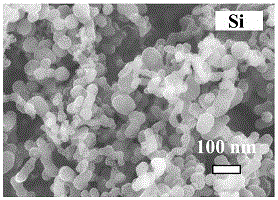

[0047] Take untreated elemental silicon as the active material, see figure 2 , figure 2 It is a scanning electron microscope picture of elemental silicon, and it can be observed that the shape of elemental silicon is spherical, and its particle size ranges from 50 to 80 nm. According to the ratio of active material: acetylene black: binder (PVDF) = 8:1:1 (mass percentage), the electrode film is made by mixing, with lithium sheet as the positive electrode and Cellgard 2300 porous membrane as the diaphragm, and 1 mol L -1 LiPF 6 / EC+DM (volume ratio 1:1) mixed solution as electrolyte, assembled into 2032 button cells. The electrochemical performance test was carried out on the Land-CT2001A (Wuhan Jinnuo Electronics) program-controlled automatic electrochemical tester. see Figure 4 , at a current density of 200 mA·g -1 The charge and discharge test was carried out under the same conditions, the voltage range was set at 0.01~1.0 V, and the initial discharge capacity was 3...

Embodiment 2

[0049] Take 5 mmol of aniline monomer and add it to 100 ml of deionized aqueous solution, and stir it magnetically for about 2 h. Then, 0.5 g of silicon powder (60 nm) was added to the above mixed solution while stirring, and after stirring evenly, ultrasonication was performed for 30 min to obtain a uniformly dispersed silicon dispersion. Subsequently, 1.14 g of ammonium persulfate (APS:ANI=1:1) was dissolved in 20 ml of deionized water, and slowly poured into the above-mentioned silicon dispersion, and kept stirring for 24 h, the solution gradually changed from the original brown to green , the above solution was filtered with a circulating water multipurpose vacuum pump, washed with deionized water and ethanol until the filtrate was colorless, and the obtained product was placed in a vacuum drying oven and dried at 60 °C for 12 h to obtain Si-0.1SA -5 PANI composite material. Active material: acetylene black: binder (SA) = 8:1:1 ratio (mass percentage) was mixed to form an...

Embodiment 3

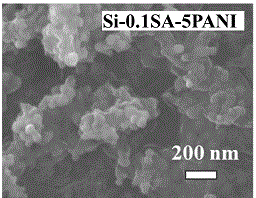

[0051] Put 0.1 g of sodium alginate powder in 100 ml of deionized water, and magnetically stir for 2 h to completely dissolve the sodium alginate, then add 5 mmol of aniline monomer, and magnetically stir for 2 h. Add 0.5 g of silicon powder (60 nm) to the above mixed solution while stirring, stir well and then ultrasonicate for 30 min to obtain a uniformly dispersed silicon dispersion. Subsequently, 1.14 g of ammonium persulfate (APS: ANI = 1: 1) was dissolved in 20 ml of deionized water, and slowly poured into the above silicon dispersion, stirring continuously for 24 h, the solution gradually changed from brown to green , the above solution was filtered with a circulating water multipurpose vacuum pump, washed with deionized water and ethanol until the filtrate was colorless, and the obtained product was placed in a vacuum drying oven and dried at 60 °C for 12 h to obtain Si-0.1SA -5PANI composite material, the morphology of this Si-0.1SA-5PANI composite material sees ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com