Preparation method of composite cathode material for lithium ion battery

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low discharge voltage and compaction density, secondary particle breakage, structural defects, etc., to achieve high energy density, improve The effect of compaction density, material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Fusion growth of monocrystalline layered lithium cobalt oxide particles and polycrystalline layered nickel cobalt manganese lithium oxide particles into a whole by the mixed sintering method of precursors 2 / Li 1.10 Ni 0.5 co 0.2 mn 0.3 o 2 Composite cathode material process:

[0041] Step 1: Preparation of nickel oxide cobalt manganese precursor:

[0042] (1) Prepare nickel sulfate, cobalt sulfate, and manganese sulfate according to the Ni:Co:Mn molar ratio of 5:2:3 to make a mixed solution with a total ion concentration of nickel, cobalt, and manganese of 3.6mol / L; use sodium hydroxide as a precipitant 1. Ammonia water is used as a complexing agent, polyethylene glycol is used as a water-soluble dispersant, and the molar amount of ammonia alkali is 0.3, and ammonia water is added in a sodium hydroxide solution of 12mol / L, and then 2% of the volume ratio of the total content is added. Polyethylene glycol is prepared as a solution for controlling the particle size...

Embodiment 2

[0049] Fusion growth of single-crystal layered lithium cobalt oxide particles and polycrystalline layered nickel-cobalt-manganese-lithium oxide particles into an integral LiCoO by intermediate mixed sintering method 2 / Li 1.10 Ni 0.5 co 0.2 mn 0.3 o 2 Composite cathode material process:

[0050] Step 1: same as Step 1 in Example 1;

[0051] Step 2: Preparation of LiCoO 2 / Li 1.10 Ni 0.5 co 0.2 mn 0.3 o 2 Composite cathode material:

[0052] ⑴ According to lithium LiCoO 2 Components, with the molar weight Li: Co=1.05 ratio, take out three cobalt tetroxide Co 3 o 4 1070g of powder and 1165.5g of lithium carbonate were placed in a mixer and mixed for 30min to form a mixture of layered lithium cobalt oxide precursors with lithium; according to Li 1.10 Ni 0.5 co 0.2 mn 0.3 o 2 Components, with a molar ratio of Li:Me(Me=Ni+Co+Mn)=1.1, weigh 916.27g of nickel hydroxide cobalt manganese precursor and 407g of lithium carbonate, and mix them in a mixer for 30min , fo...

Embodiment 3

[0056] Fusion growth of monocrystalline layered lithium cobalt oxide particles and polycrystalline layered nickel cobalt manganese lithium oxide particles into a whole by the mixed sintering method of the final product 2 / Li 1.10 Ni 0.5 co 0.2 mn 0.3 o 2 Composite cathode material process:

[0057] Step 1: same as Step 1 in Example 1;

[0058] Step 2: Preparation of LiCoO 2 / Li 1.10 Ni 0.5 co 0.2 mn 0.3 o 2 Composite cathode material:

[0059] ⑴ According to LiCoO 2 Components, with the molar ratio of Li:Co=1.05, take out cobalt carbonate CoCO 3 1190g of powder and 388.5g of lithium carbonate were placed in a mixer and mixed uniformly for 30min to form a mixture of layered lithium cobalt oxide precursors with lithium; according to Li 1.10 Ni 0.5 co 0.2 mn 0.3 o 2 Components, with a molar ratio of Li:Me(Me=Ni+Co+Mn)=1.1, weigh 916.27g of the nickel hydroxide cobalt manganese precursor prepared in step 1 and 407g of lithium carbonate, and place them on a mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

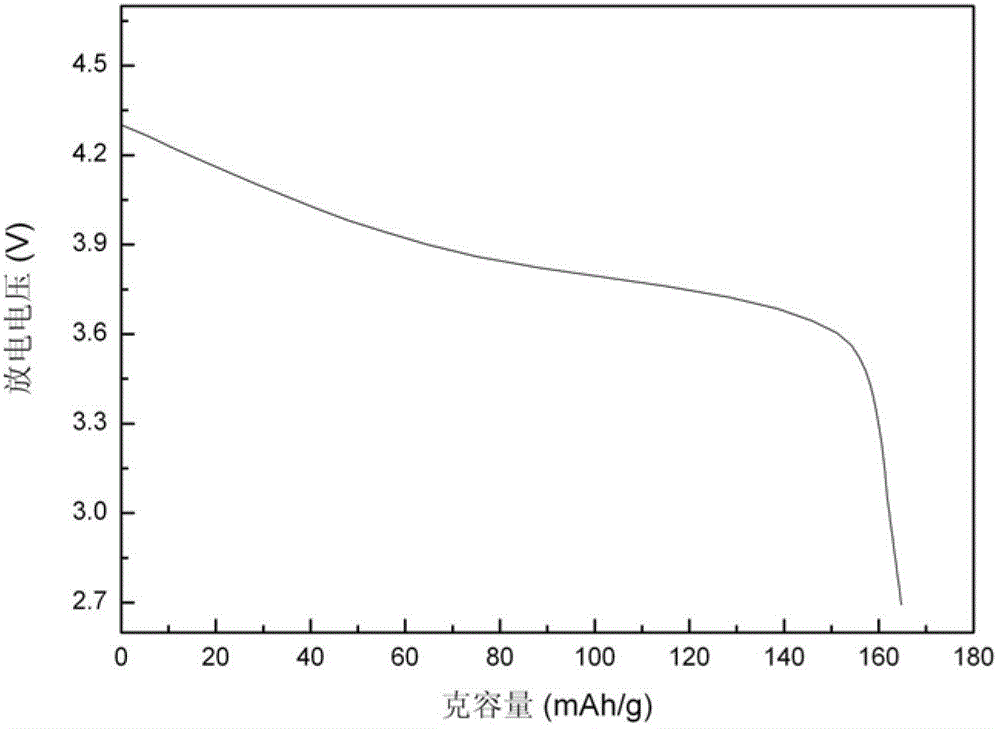

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com