Biodegradable lubricating grease

A technology of biodegradation and lubricating grease, applied in the direction of lubricating compositions, etc., to achieve the effect of excellent conventional physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

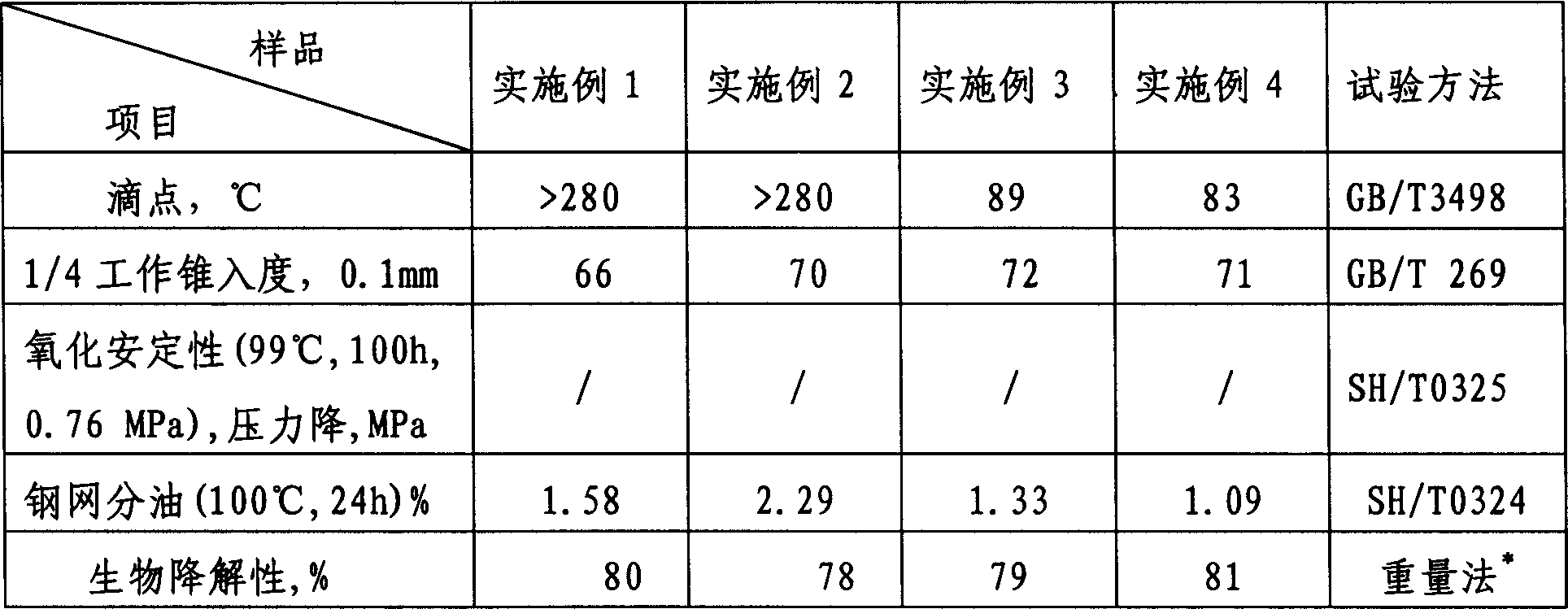

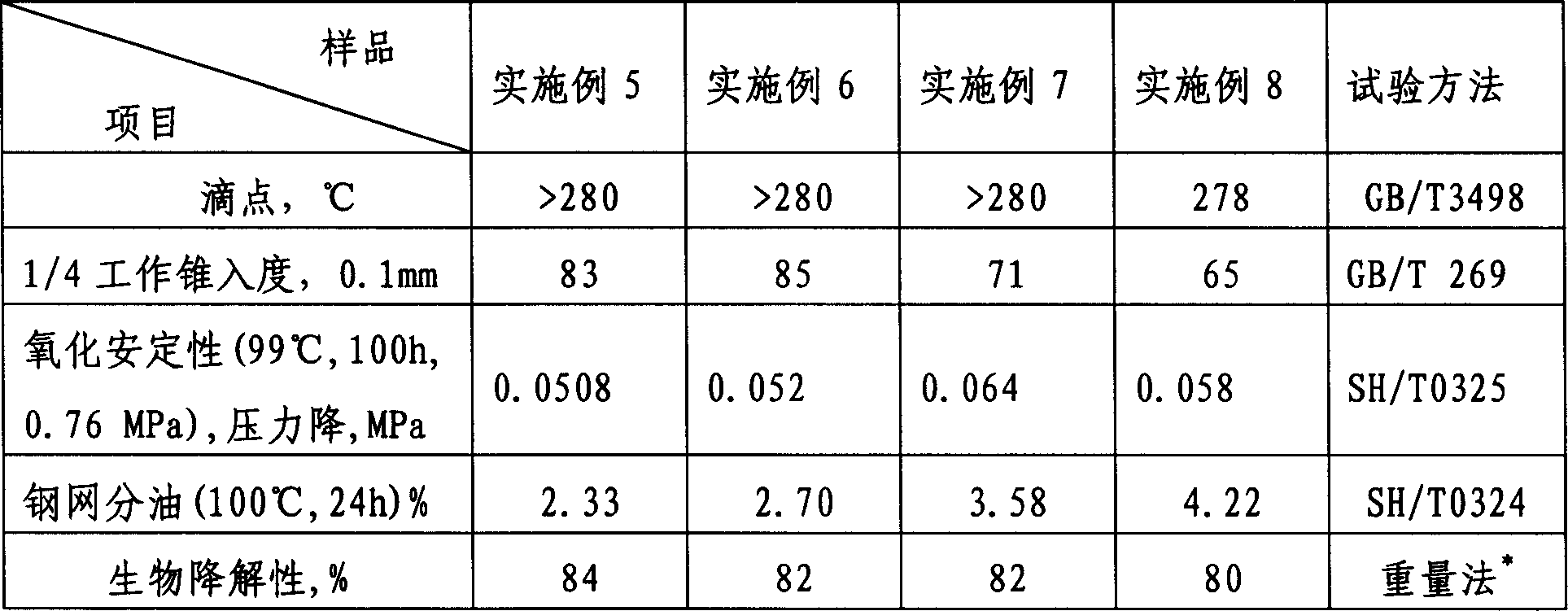

Examples

Embodiment 1

[0020] composition:

[0021] Castor Oil: 75Wt%

[0022] Complex calcium thickener: 25Wt%

[0023] In the thickener: organic acid: calcium hydroxide = 2:1;

[0024] 12-hydroxystearic acid: octanoic acid: glacial acetic acid = 1:0.5:5

[0025] preparation:

[0026] Add molten calcium hydroxide to 1 / 2 of the base oil, add glacial acetic acid at room temperature, add n-octanoic acid when heated to about 50°C, add 12-hydroxystearic acid at around 80°C, heat up to 210°C and add remaining 1 / 2 base oil, ground three times after cooling.

Embodiment 2

[0028] composition:

[0029] Castor oil: 79.5Wt%

[0030] Composite calcium thickener: 20Wt%

[0031] Alkylated diphenylamine (SIBA Refining, L-57): 0.5wt%

[0032] In the thickener: 12-hydroxystearic acid: n-octanoic acid: glacial acetic acid = 1:0.29:5;

[0033] Organic acid: calcium hydroxide = 2:1.

[0034] Preparation: same as Example 1, just add antioxidant when cooling.

Embodiment 3

[0036] composition

[0037] Castor Oil: 89Wt%

[0038] Anhydrous calcium thickener: 11Wt%

[0039] Thickener: 12-hydroxystearic acid: calcium hydroxide = 2:1, excess calcium hydroxide 5%

[0040] preparation:

[0041] Mix 12-hydroxystearic acid and base oil, heat up to 80-85°C, add calcium hydroxide alkali solution after acid dissolution, heat up to 135°C after saponification, cool and grind three times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com