A kind of environment-friendly lubricating grease for vehicles

A lubricating grease and environment-friendly technology, which is applied in the field of automotive lubricating grease and its preparation, achieves the effects of low production cost, increased maximum non-jamming load, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

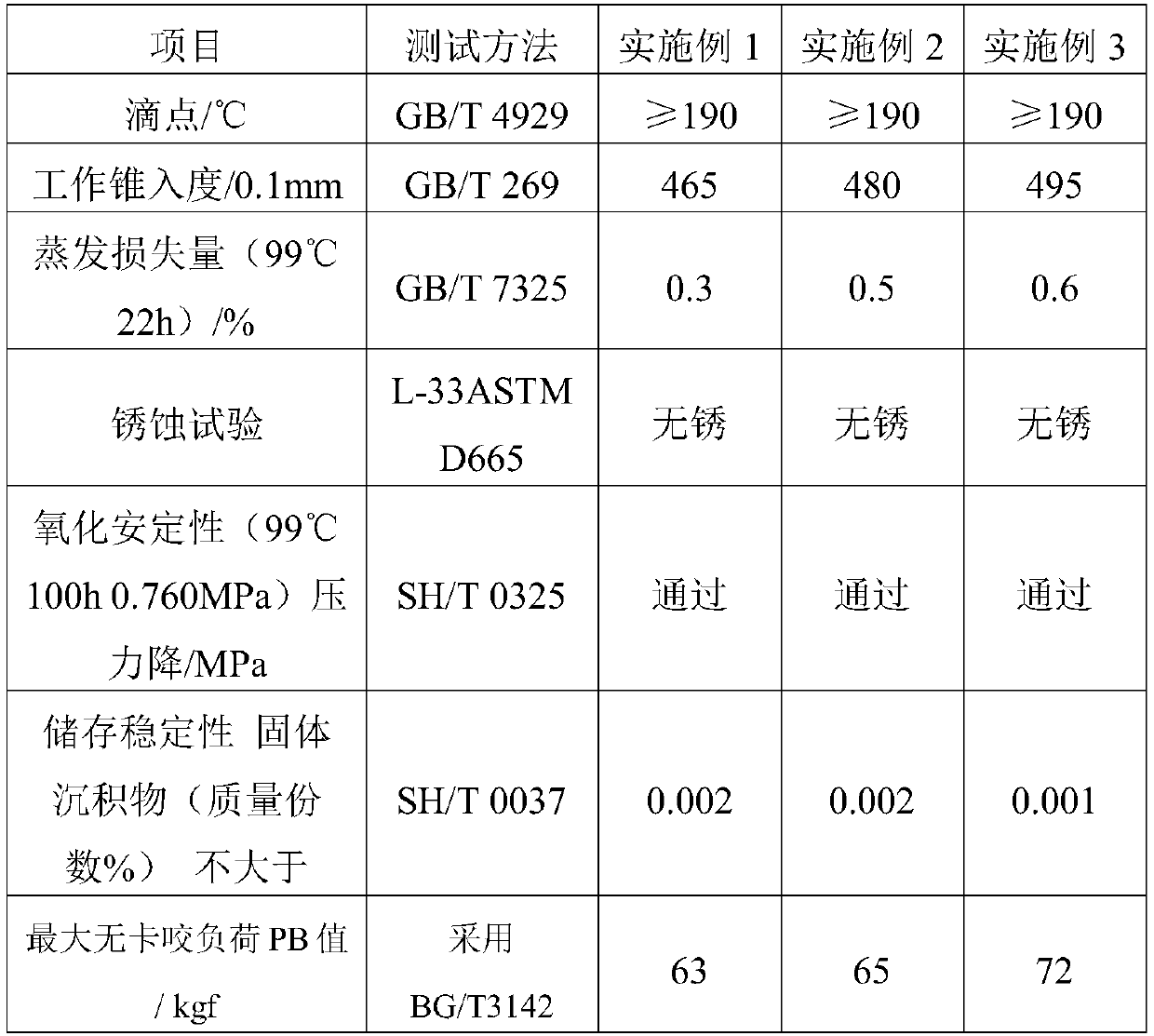

Examples

Embodiment 1

[0030] An environment-friendly lubricating grease for vehicles, comprising the following components in parts by weight: 68 parts of plant-based synthetic oil, 10 parts of sodium-based bentonite, 2 parts of sasol wax, 3 parts of chlorinated paraffin, 3 parts of detergent and dispersant, emulsifying 3 parts of anti-oxidant, 3 parts of extreme pressure agent, 3 parts of antioxidant, 2 parts of anti-corrosion and anti-rust agent, 15 parts of organic acid, 12 parts of calcium hydroxide and 20 parts of water.

[0031] The plant-based synthetic oil comprises the following components in parts by weight: 10 parts of castor oil, 10 parts of cottonseed oil, 30 parts of water, 5 parts of triethanolamine, 3 parts of boric acid and 10 parts of triethanolamine oleate.

[0032] The preparation method of the plant-based synthetic oil described in this embodiment is: Step (A) The preparation method of the plant-based synthetic oil comprises the following steps:

[0033] Step A-1) Mix castor oil...

Embodiment 2

[0048] An environment-friendly lubricating grease for vehicles, comprising the following components in parts by weight: 100 parts of plant-based synthetic oil, 15 parts of sodium-based bentonite, 4 parts of sasol wax, 6 parts of chlorinated paraffin, 6 parts of detergent and dispersant, emulsifying 6 parts of anti-oxidant, 6 parts of extreme pressure agent, 6 parts of antioxidant, 4 parts of anti-corrosion and anti-rust agent, 20 parts of organic acid, 15 parts of calcium hydroxide and 30 parts of water.

[0049] The plant-based synthetic oil comprises the following components in parts by weight: 15 parts of castor oil, 15 parts of cottonseed oil, 40 parts of water, 10 parts of triethanolamine, 8 parts of boric acid, and 12 parts of triethanolamine oleate.

[0050] The preparation method of the plant-based synthetic oil described in this embodiment is: Step (A) The preparation method of the plant-based synthetic oil comprises the following steps:

[0051] Step A-1) Mix castor ...

Embodiment 3

[0066] An environment-friendly lubricating grease for vehicles, comprising the following components in parts by weight: 85 parts of plant-based synthetic oil, 12 parts of sodium-based bentonite, 3 parts of sasol wax, 5 parts of chlorinated paraffin, 5 parts of detergent and dispersant, emulsifying 5 parts of anti-corrosion agent, 5 parts of extreme pressure agent, 5 parts of antioxidant, 3 parts of anti-corrosion and anti-rust agent, 18 parts of organic acid, 13 parts of calcium hydroxide and 25 parts of water.

[0067] The plant-based synthetic oil comprises the following components in parts by weight: 12 parts of castor oil, 13 parts of cottonseed oil, 35 parts of water, 8 parts of triethanolamine, 6 parts of boric acid and 11 parts of triethanolamine oleate.

[0068] The preparation method of the plant-based synthetic oil described in this embodiment is: Step (A) The preparation method of the plant-based synthetic oil comprises the following steps:

[0069] Step A-1) Mix ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com