Degradable lubricating grease for locomotive wheel flange and preparation method

A technology of lubricating grease and rim, applied in the field of lubricating materials in the chemical industry, can solve the problems of soil, water and air pollution, damage to the ecological environment and ecological balance, etc., and achieve the effect of excellent conventional physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

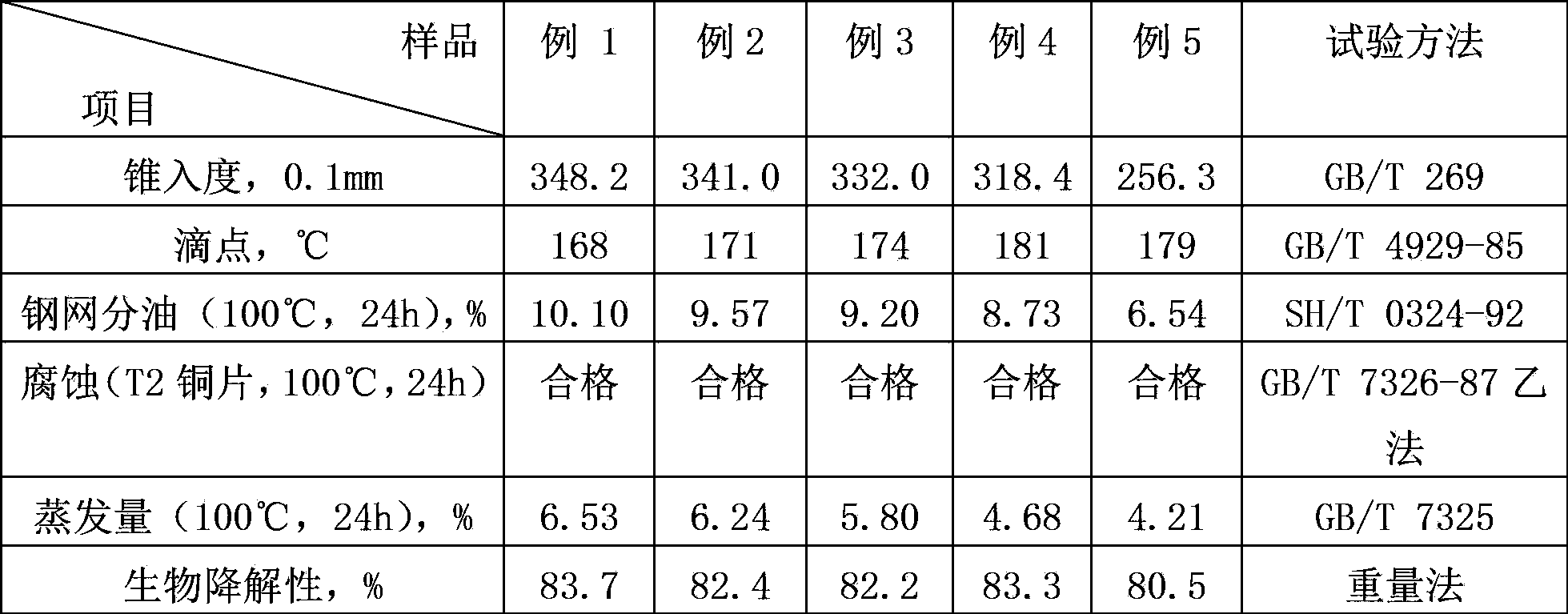

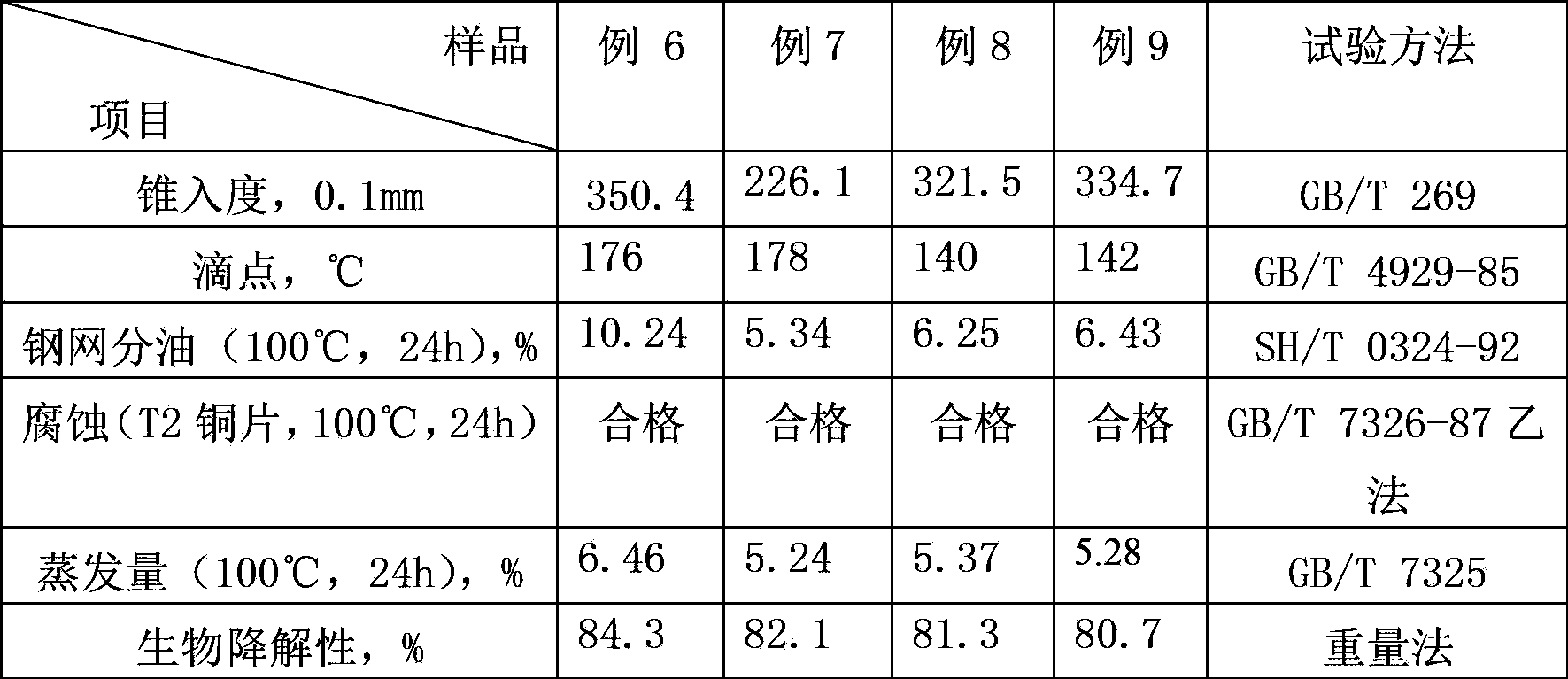

Examples

Embodiment 1

[0037] A lithium-based lubricating grease for locomotive rims (i.e. degradable lubricating grease for locomotive rims) of this embodiment is prepared from the following raw materials in weight percentage: 83wt% diisooctyl adipate is used as the base oil , 11wt% thickening agent (it is made up of 12-hydroxystearic acid and the lithium hydroxide aqueous solution that concentration is 15wt%, and the molar ratio of 12-hydroxystearic acid and lithium hydroxide is 1:1; Saponification reaction makes 12-hydroxystearate lithium soap), add 1.5wt% tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 1010), 2wt% Barium petroleum sulfonate (petroleum sulfonate), 1 wt% polyisobutylene, 1 wt% molybdenum dibutyldithiocarbamate, 0.5 wt% graphite.

[0038] The above-mentioned preparation method of degradable lubricating grease for a locomotive wheel rim adopts a one-step saponification method, comprising the following steps:

[0039] 1) Select raw mate...

Embodiment 2

[0042] A lithium-based lubricating grease for locomotive rims (i.e., degradable lubricating grease for locomotive rims) of this embodiment is prepared from the following raw materials in weight percentage: 84wt% diisooctyl adipate is used as the base oil , the thickening agent of 10wt% (it is made up of the lithium hydroxide aqueous solution of 15wt% by 12 hydroxystearic acid and concentration, the mol ratio of 12-hydroxystearic acid and lithium hydroxide is 1:1; Saponification reaction makes 12 -Lithium hydroxystearate soap), add 1.5wt% tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol (antioxidant 1010), 2wt% petroleum Barium sulfonate, 1 wt% polyisobutylene, 1 wt% molybdenum dibutyldithiocarbamate, 0.5 wt% graphite.

[0043] The above-mentioned preparation method of degradable lubricating grease for a locomotive wheel rim adopts a one-step saponification method, comprising the following steps:

[0044] 1) Select raw materials according to the above...

Embodiment 3

[0047] A lithium-based lubricating grease for locomotive rims (i.e. degradable lubricating grease for locomotive rims) of this embodiment is prepared from the following raw materials in weight percentages: 82wt% diisooctyl adipate is used as the base oil , 12wt% thickening agent (it is made up of 12-hydroxystearic acid and the lithium hydroxide aqueous solution that concentration is 15wt%, and the molar ratio of 12-hydroxystearic acid and lithium hydroxide is 1:1; Saponification reaction makes 12-hydroxystearate lithium soap), add 1.5wt% tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 1010), 2wt% Barium petroleum sulfonate, 1 wt% polyisobutylene, 1 wt% molybdenum dibutyldithiocarbamate, 0.5 wt% graphite.

[0048] The above-mentioned preparation method of degradable lubricating grease for a locomotive wheel rim adopts a one-step saponification method, comprising the following steps:

[0049] 1) Select raw materials according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| cone penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com