Graphene heating film and preparation method thereof

A technology of graphene heating film and graphene film, applied in the field of graphene heating film and its preparation, can solve the problems of long transfer time and low transfer rate, and achieve the effects of short transfer time, high transfer rate and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

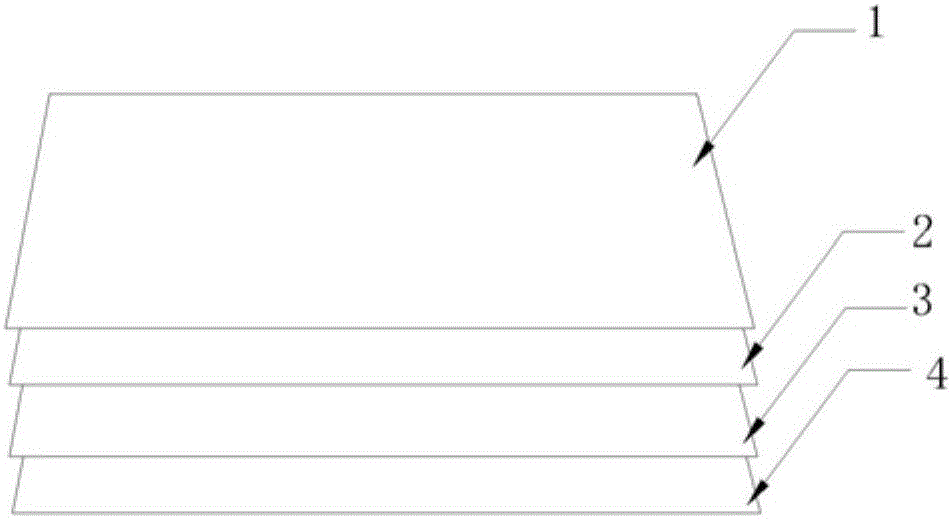

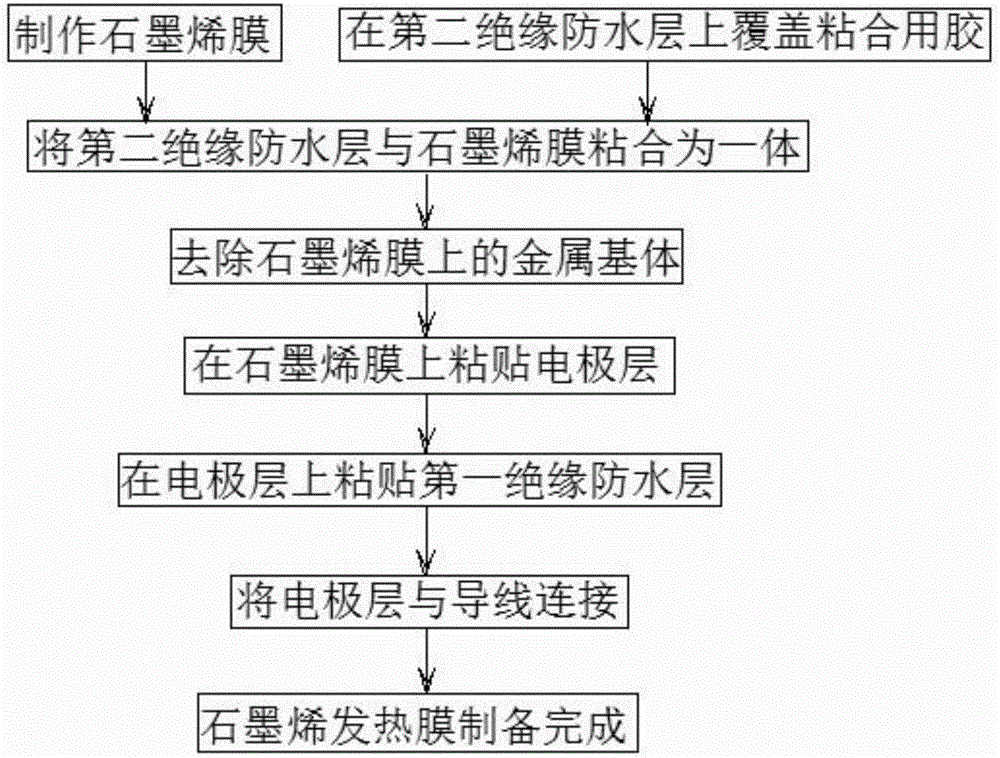

[0066] Such as figure 2 As shown, a kind of graphene heating film preparation method provided by the invention comprises the following process steps:

[0067] 1), the making of graphene film, adopts chemical vapor deposition method to prepare graphene film on the surface of metal substrate;

[0068] 2), adopting the method of spraying, brushing or rolling to cover the adhesive glue on the second insulating and waterproof layer 4;

[0069] 3), the second insulating and waterproof layer 4 covered with glue for bonding is bonded together with the graphene film;

[0070] 4), adopt the method for mechanical stripping or electrochemical corrosion to remove the metal matrix on the graphene film, make the graphene film with insulating waterproof layer;

[0071] 5), paste the electrode layer 2 on the graphene film that is covered with the first insulating and waterproof layer 1;

[0072] 6), pasting the first insulating and waterproof layer 1 on the electrode layer 2;

[0073] 7) ...

Embodiment 1

[0101] 1), choose to prepare a layer of graphene film on the surface of the metal substrate (such as aluminum foil, copper foil or nickel foil) by chemical vapor deposition method, at a temperature of 25 ° C, normal pressure, inert gas (such as helium, neon, etc.) 1. Grow in a sterile environment for 15 hours to prepare a graphene film with a thickness of 30 μm;

[0102] 2) Select one or more of polyurethane, polystyrene, epoxy resin and acrylate as the bonding glue, and spray, brush or roll on the second insulating and waterproof layer 4 (such as PVC film) , PE film or PET film) to prepare a bonding layer with a thickness of about 150-280 μm;

[0103] 3) Cover the PVC film, PE film or PET film with the adhesive layer on the surface of the substrate with graphene growing, and act for 5 hours at a temperature of 50°C and a pressure of 50Pa, and the adhesive layer will be covered. The second insulating and waterproof layer 4 of the layer is bonded as a whole with the graphene f...

Embodiment 2

[0109] The difference between embodiment 2 and embodiment 1 is only that step 1), step 3) and step 4) are different, and other steps are the same as embodiment 1).

[0110] 1), choose to prepare a layer of graphene film on the surface of the metal substrate (such as aluminum foil, copper foil or nickel foil) by chemical vapor deposition method, at a temperature of 25 ° C, normal pressure, inert gas (such as helium, neon, etc.) 1. Grow in a sterile environment for 17 hours to prepare a graphene film with a thickness of 38 μm;

[0111] 3) Cover the PVC film, PE film or PET film with an adhesive layer on the surface of the substrate on which graphene grows, and act for 3.2 hours at a temperature of 90 ° C and a pressure of 50 Pa, and the adhesive layer will be covered. The second insulating and waterproof layer 4 of the junction layer is bonded as a whole with the graphene film;

[0112] 4), remove the metal substrate on the graphene film by mechanical stripping or electrochemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com