Method for preparing sodium lignosulfonate and application of sodium lignosulfonate as a dye dispersant

A technology of sodium lignosulfonate and lignin, which is applied in the field of preparing sodium lignosulfonate and sodium lignosulfonate as a dye dispersant, which can solve the problems of low heat resistance stability and heavy staining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

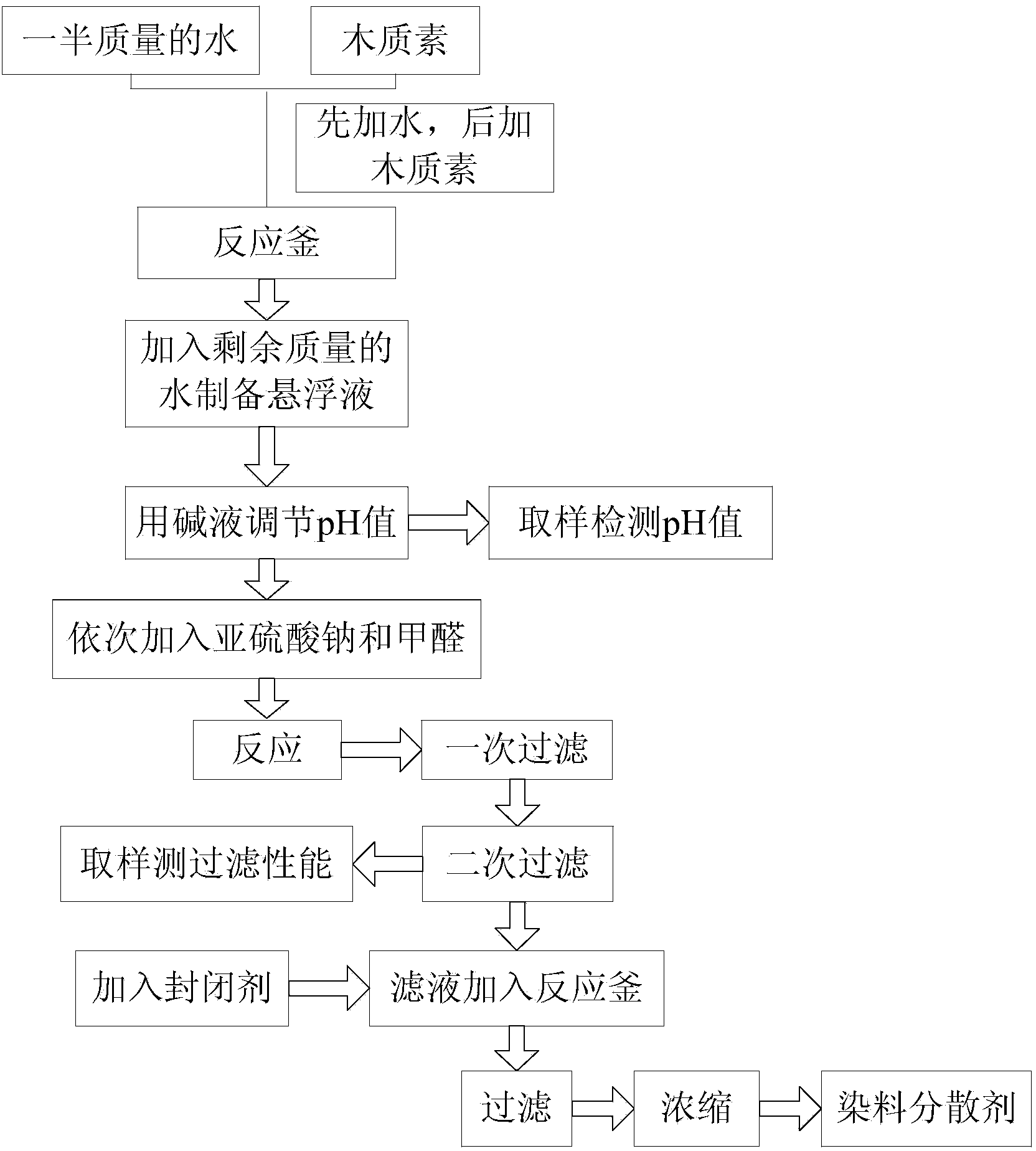

Method used

Image

Examples

Embodiment 1

[0061] First add 1000kg of water to a 5 cubic meter reactor, start stirring, add 600kg of lignin to it dry, and then add an appropriate amount of water to make a suspension with a mass concentration of 20%;

[0062] While stirring, add such as NaOH solution to adjust the pH value of the suspension to 7.5, then add 1.3mmol / g lignin sodium sulfite and 1.3mmol / g lignin formaldehyde to it in turn; turn on the steam and heat up to 120°C and keep it warm for 3h . After the reaction is completed, the temperature is lowered to 50°C for two plate and frame filtrations;

[0063] 0.7 mmol / g lignin blocking agent epichlorohydrin was added to the obtained filtrate, and the reaction was continued at 90° C. for 1 h. After the reaction is completed, concentrate to a solid content of 30% to obtain sodium lignosulfonate.

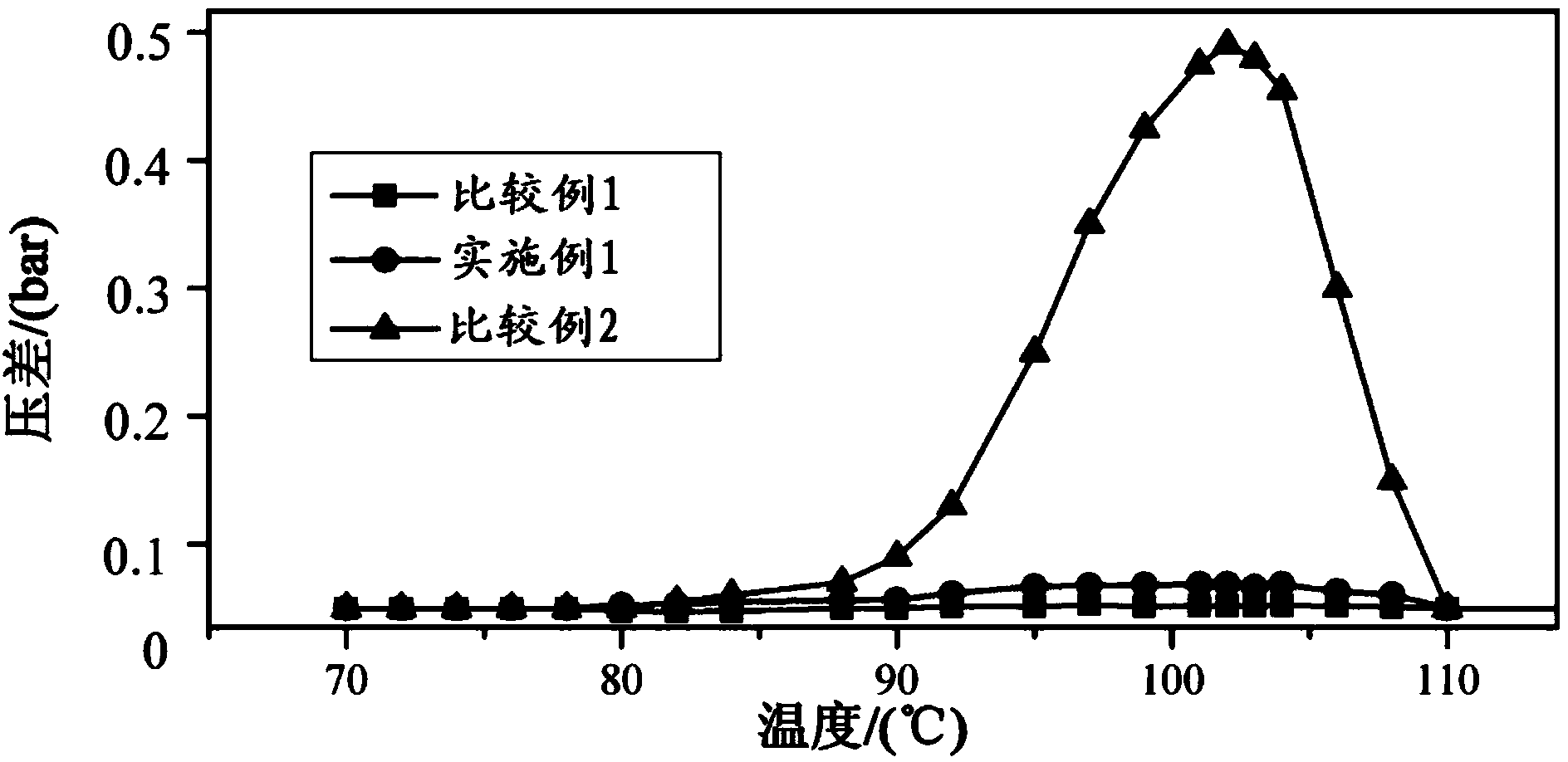

[0064] The sodium lignosulfonate obtained by the present invention is used as a dye dispersant, and the obtained sodium lignosulfonate is subjected to a performance test, a...

Embodiment 2

[0085] First add 1000kg of water to a 5 cubic meter reactor, start stirring, and add 600kg of lignin to dry it, and then add an appropriate amount of water to make a suspension with a mass concentration of 20%;

[0086] Add NaOH solution to it while stirring to adjust the pH value of the suspension to 8.5, then add 1.4mmol / g lignin sodium sulfite and 1.4mmol / g lignin formaldehyde to it in turn; turn on the steam and raise the temperature to 120°C and keep it warm for 3h. After the reaction is completed, the temperature is lowered to 50°C for two plate and frame filtrations;

[0087] Add 0.7 mmol / g lignin blocking agent epichlorohydrin to the desired filtrate, and continue to react at 90° C. for 1 h. After the reaction is completed, concentrate to a solid content of 35% to obtain sodium lignosulfonate.

[0088] The performance when the sodium lignosulfonate obtained according to the method test described in Example 1 is used as a dye dispersant, the results show that when the ...

Embodiment 3

[0090] First add 1000kg of water to a 5 cubic meter reactor, start stirring, add 600kg of lignin to it dry, and then add an appropriate amount of water to form a suspension with a mass concentration of 15%;

[0091] Add NaOH solution to it while stirring to adjust the pH value of the suspension to 7.5, then add 1.3mmol / g lignin sodium sulfite and 1.3mmol / g lignin formaldehyde to it in turn; turn on the steam and raise the temperature to 120°C and keep it warm for 3h. After the reaction is completed, the temperature is lowered to 50°C for two plate and frame filtrations;

[0092] Add 0.7 mmol / g lignin blocking agent ethylene oxide to the obtained filtrate and continue to react at 80° C. for 1 h. After the reaction is completed, concentrate to a solid content of 25% to obtain sodium lignosulfonate.

[0093] The performance when the sodium lignosulfonate obtained according to the method test described in Example 1 is used as a dye dispersant, the results show that when the sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com