Sulfur-fixing combustion-supporting high-temperature profile control agent, and preparation method and application thereof

A profile control agent, high temperature technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of other components not being recycled, crude oil not being fully recovered, and the difficulty of harmless treatment. , to achieve good application prospects, saving profile control costs, and good suspension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

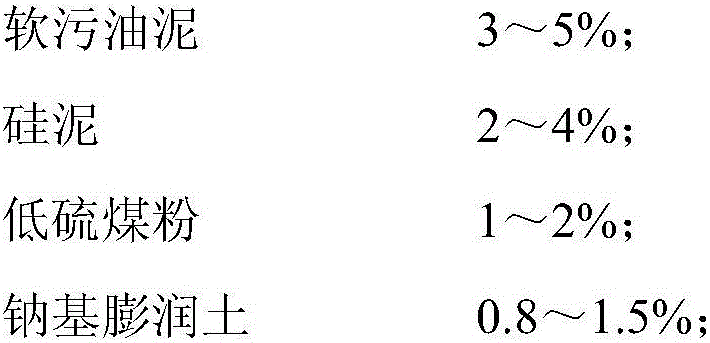

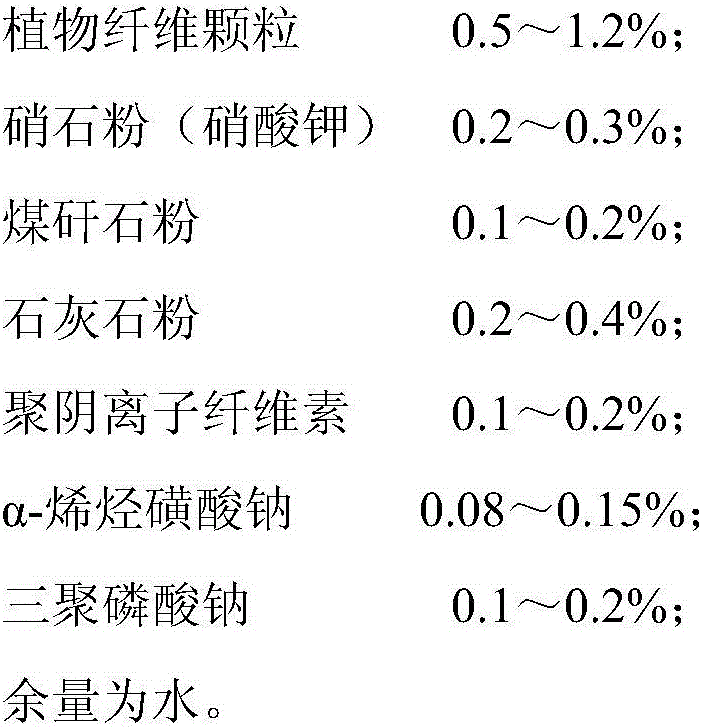

[0061] This embodiment provides a sulfur-fixing, combustion-supporting, high-temperature profile control agent, which is prepared from the following raw materials, based on the total weight of the sulfur-fixing, combustion-supporting, high-temperature profile-controlling agent as 100%:

[0062]

[0063]

[0064] The sulfur-fixing combustion-supporting high-temperature profile control agent provided in this example is prepared according to the following steps:

[0065] (1) Add an appropriate amount of water and polyanionic cellulose into the reaction kettle, and stir for 15 minutes at normal temperature;

[0066] (2) Add soft sludge, silica mud and low-sulfur coal powder to the reaction kettle solution obtained in the above step (1) successively, and stir for 20 minutes at normal temperature;

[0067] (3) Add sodium bentonite, sodium α-olefin sulfonate and sodium tripolyphosphate successively to the reactor solution obtained in the above step (2), and stir for 12 minutes ...

Embodiment 2

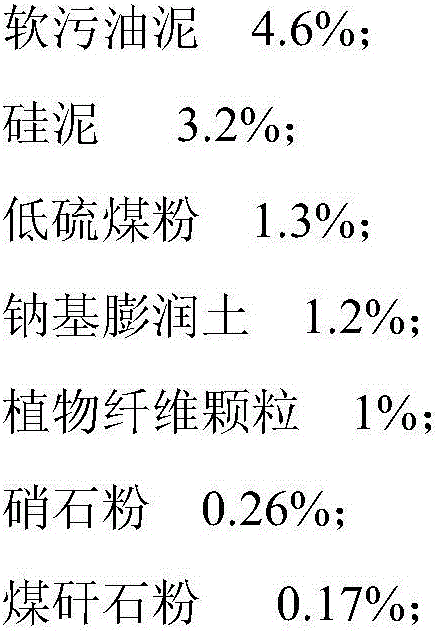

[0080] This embodiment provides a sulfur-fixing, combustion-supporting, high-temperature profile control agent, which is prepared from the following raw materials, based on the total weight of the sulfur-fixing, combustion-supporting, high-temperature profile-controlling agent as 100%:

[0081]

[0082] The sulfur-fixing combustion-supporting high-temperature profile control agent provided in this example is prepared according to the following steps:

[0083] (1) Add appropriate amount of water and polyanionic cellulose into the reaction kettle, and stir for 10 minutes at normal temperature;

[0084] (2) Add soft sludge, silica mud and low-sulfur coal powder to the reaction kettle solution obtained in the above step (1) successively, and stir for 15 minutes at normal temperature;

[0085] (3) Add sodium bentonite, sodium α-olefin sulfonate and sodium tripolyphosphate successively to the reactor solution obtained in the above step (2), and stir for 12 minutes at normal tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com