Cation amino silicone oil micro-emulsion and preparation method thereof

A technology of amino silicone oil and cationic emulsifier, used in textiles, papermaking, fiber processing, etc., can solve the problems of production of floating oil and poor stability, and achieve the effect of firm orientation adsorption, excellent heat resistance stability, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method step of cationic amino silicone oil microemulsion is as follows:

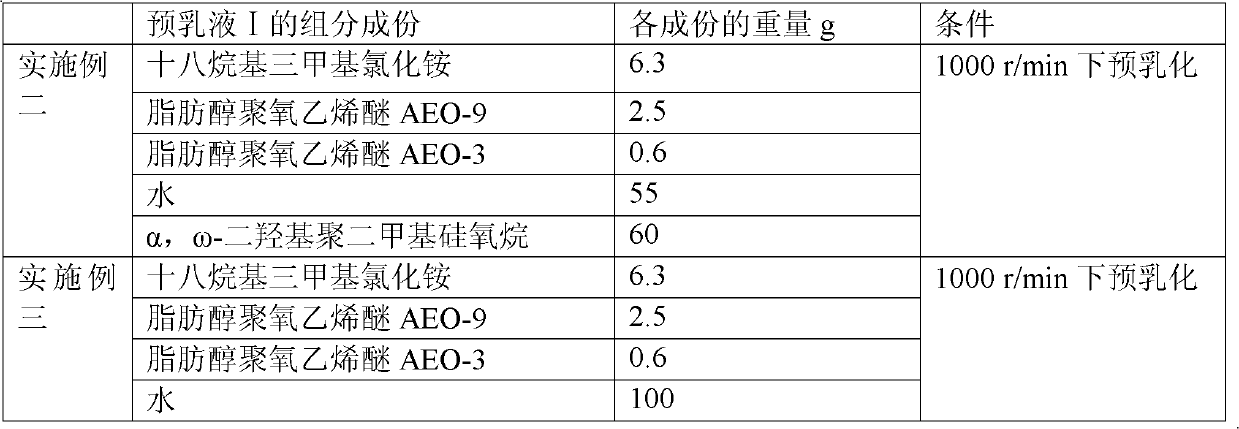

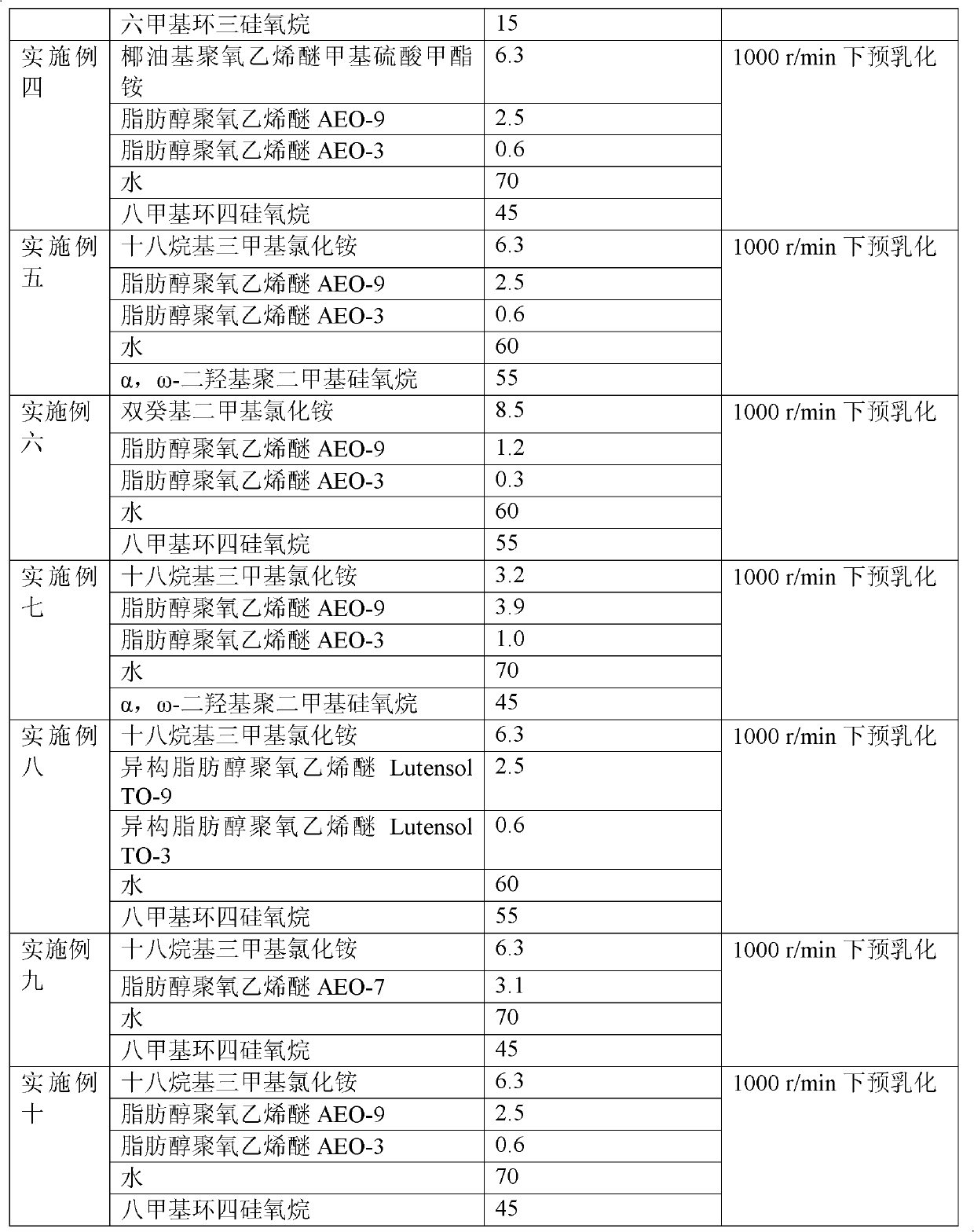

[0033] a) Pre-emulsification of organosiloxane monomer, cationic emulsifier, and nonionic emulsifier into pre-emulsion I;

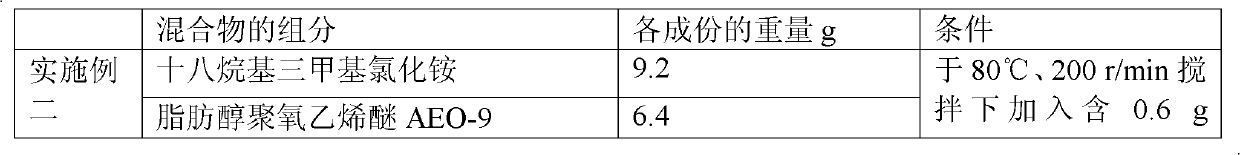

[0034] b) Put water, cationic emulsifier, non-ionic emulsifier in the reactor and heat to 60~90 ℃, then add catalyst; Get 50% pre-emulsion I dropwise from the pre-emulsion I generated in step a) Inside the reactor;

[0035] c) adding a silane coupling agent, a cationic emulsifier, and a nonionic emulsifier to the remaining 50% of the pre-emulsion I generated in step a) to pre-emulsify into a pre-emulsion II;

[0036] d) After the addition of the pre-emulsion I in step b) is completed, add the pre-emulsion II dropwise into the reactor; the total time of adding the pre-emulsion I and pre-emulsion II is less than or wait for 4 hours.

[0037] e) After the heat preservation reaction for 6-12 hours, the temperature is lowered to room temperature, and a neutralizi...

Embodiment 1

[0039] a) 6.3g octadecyltrimethylammonium chloride, 2.5g fatty alcohol polyoxyethylene ether AEO-9 and 0.6g fatty alcohol polyoxyethylene ether AEO-3, 70g water, 45g octamethylcyclotetrasilane Mix oxane, shear at 1000r / min, and pre-emulsify into pre-emulsion I;

[0040] b) Add 9.2g octadecyltrimethylammonium chloride, 6.4g fatty alcohol polyoxyethylene ether AEO-9 and 1.4g fatty alcohol polyoxyethylene ether AEO-3, 80g water, stirred at 200r / min to 80°C, then added an aqueous solution containing 0.9g of potassium hydroxide (KOH) catalyst, then the pre-emulsion prepared in a) Half of I was added dropwise in the reaction flask within 1.5h;

[0041] c) Add 0.35g of octadecyltrimethylammonium chloride, 0.2g of fatty alcohol polyoxyethylene ether AEO-9, 0.5g of N-β-aminoethyl- γaminopropylmethyldimethoxysilane and 0.2g of N-β-aminoethyl-γaminopropyltrimethoxysilane were sheared at 1000r / min and pre-emulsified into pre-emulsion II;

[0042] d) After the pre-emulsion I is added dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com