Modified heat-resistant silicone rubber and preparation method thereof

A silicone rubber and heat-resistant technology, applied in the field of modified heat-resistant silicone rubber and its preparation, can solve the problems of poor low temperature resistance and high price, and achieve the effects of good heat resistance and excellent heat resistance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] According to the components specified in the following Table 1, weigh the raw materials, dissolve the chloroplatinic acid in anhydrous isopropanol and stir fully to completely dissolve the chloroplatinic acid and leave it to stand to obtain the chloroplatinic acid-isopropanol solution; Disperse vinyl silicone oil, quartz powder, carbon black, phenyl silicone oil, cerium oxide and inhibitors in a high-speed shearing machine for 90-110 minutes, then cool down to 40-50°C, and then add chloroplatinic acid- Under isopropanol solution and hydrogen-containing silicone oil, mix and stir for 30-50 minutes, and then solidify at room temperature for 1-2 days to obtain the finished product. Its physical and mechanical performance index test was carried out. The test results are listed in Table 1.

Embodiment 2

[0020] The method of Example 1 was repeated according to the content of each component specified in Table 1 below, and the test results are listed in Table 1.

Embodiment 3

[0022] The method of Example 1 was repeated according to the content of each component specified in Table 1 below, and the test results are listed in Table 1.

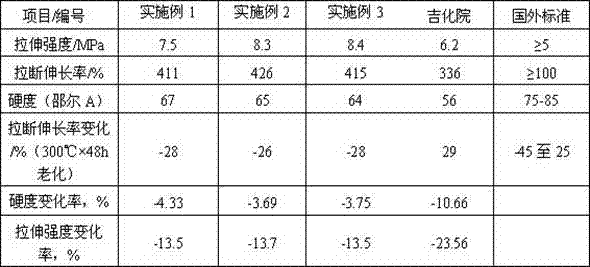

[0023] Table 1 Table of components of Examples 1-3.

[0024]

[0025] 1. Performance testing

[0026] Hardness (Shore A) is tested according to GB / T 531-1999; tensile strength and elongation at break are tested according to GB / T 528-1998; thermogravimetric analysis is tested according to ISO11358-1997.

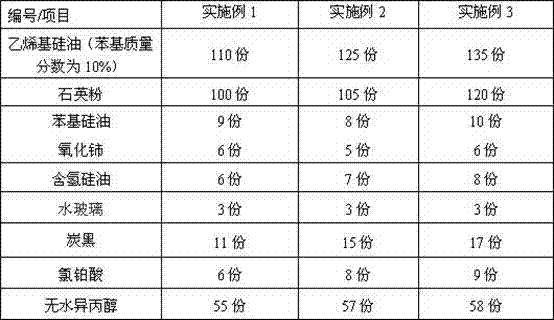

[0027] 1. Test the performance of the high-temperature-resistant silicone rubber prepared in Examples 1-3, and compare it with the national standard and products from other origins. The comparison results are shown in Table 2.

[0028] Table 2 Comparison table of the rational index of the high temperature resistant silicone rubber prepared in Example 1-3 with the national standard and products from other origins.

[0029]

[0030] It can be seen from Table 2 that the change rate of hardness of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com