Preparation method of ice blast base oil with natural pungent and sweet note

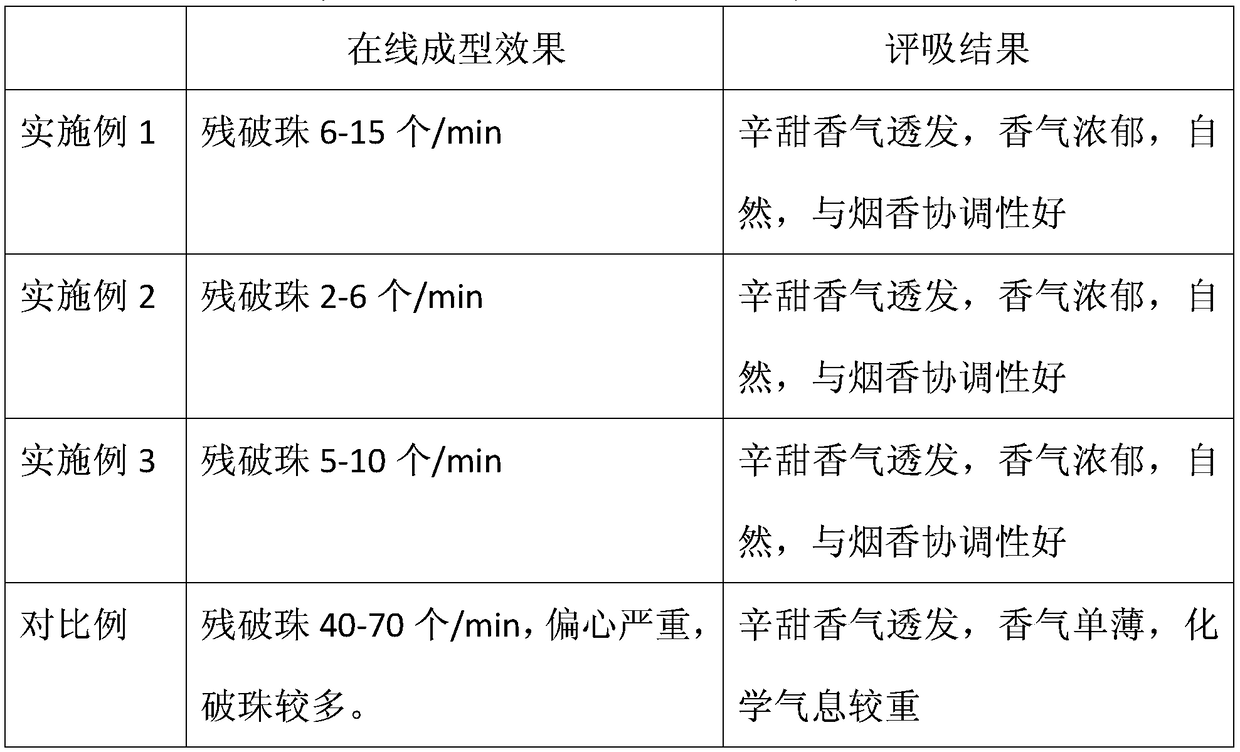

A technology of base oil and fragrance, which is applied in the field of preparation of popcorn base oil, can solve the problems of affecting the molding of popcorn, weak aroma of synthetic essence, unstable state of popcorn, etc., and achieves the solution of thin aroma, rich aroma and compatibility good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1 provides a method for preparing quick-bead base oil with natural pungent and sweet flavor, and the specific steps are as follows:

[0015] (1) Take 100g of the raw material parsnip and 200g of cassia twig, add 10 times the weight of the mixed raw material with tap water, soak at room temperature for 8, then heat to 65°C under normal pressure for reflux extraction for 2h, collect the distillate with a condenser, and separate the oil and water Obtain volatile oil, and then dissolve the volatile oil into polyglycerol fatty acid ester 3000 times its weight;

[0016] (2) Add 0.1‰ of Tween 60 by weight to the mixture obtained in step (1), filter to remove impurities and insolubles. The filtrate is sonicated for 0.5h at a temperature of 30℃ and a frequency of 30kHz. After standing for 2 hours, the quick-bead base oil with natural pungent and sweet fragrance is obtained.

Embodiment 2

[0017] Example 2 provides a method for preparing quick-bead base oil with natural pungent and sweet flavor. The specific steps are as follows:

[0018] (1) Take 200g of the raw materials of parsnips and 100g of cassia twigs, add 8 times the weight of the mixed raw materials in tap water, soak at room temperature for 12, heat to 60℃ under normal pressure and reflux for extraction for 5 hours, collect the distillate with a condenser, and separate the oil and water Obtain the volatile oil, and then dissolve the volatile oil into 5000 times the polyglycerol fatty acid ester;

[0019] (2) Add 0.3‰ of Tween 60 by weight to the mixture obtained in step (1), filter to remove impurities and insolubles, and the filtrate is sonicated for 1h at a temperature of 40°C and a frequency of 35kHz, and then left to stand after the ultrasonic is finished. 4 hours, it is the said base oil for pop pearls with natural sweet fragrance.

Embodiment 3

[0020] Example 3 provides a method for preparing quick-bead base oil with natural pungent and sweet flavor, and the specific steps are as follows:

[0021] (1) Take 200g of raw materials, fenfeng, 200g of cassia twigs, add 6 times the weight of the mixed raw materials with tap water, soak at room temperature for 8, then heat to 55°C under normal pressure for reflux extraction for 4 hours, collect the distillate with a condenser, and separate the oil and water Obtain the volatile oil, and then dissolve the volatile oil into the polyglycerol fatty acid ester 10,000 times its weight;

[0022] (2) Add 0.1‰ of Tween 60 by weight to the mixture obtained in step (1), filter to remove impurities and insolubles. The filtrate is sonicated for 1.5h at a temperature of 50°C and a frequency of 25kHz. Leave it for 24 hours, and it will be the said quick-bead base oil with natural pungent and sweet fragrance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com