Flavor for improving taste of heated non-burning tobacco and preparation method and application thereof

A heat-not-burn, flavoring technology, applied in the field of tobacco flavors and fragrances, can solve problems such as affecting consumers' sensory experience, delayed flavor product development, and uncomfortable aftertaste, and achieve reliable guarantee of feasibility, improved comfort, and clean mouth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

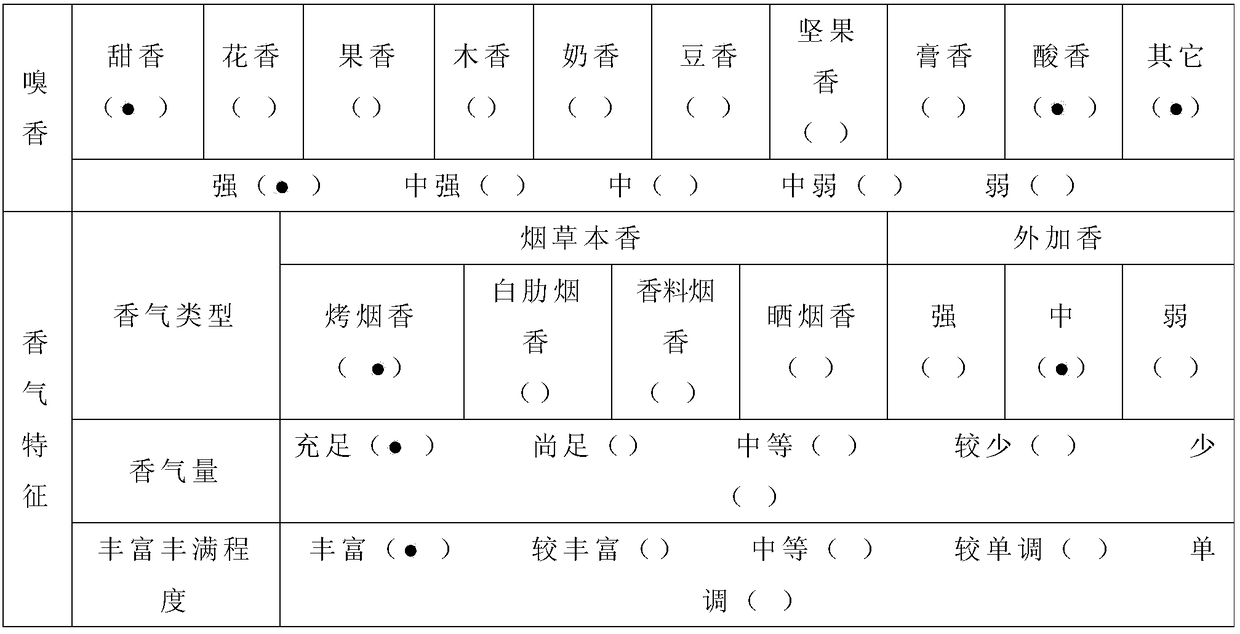

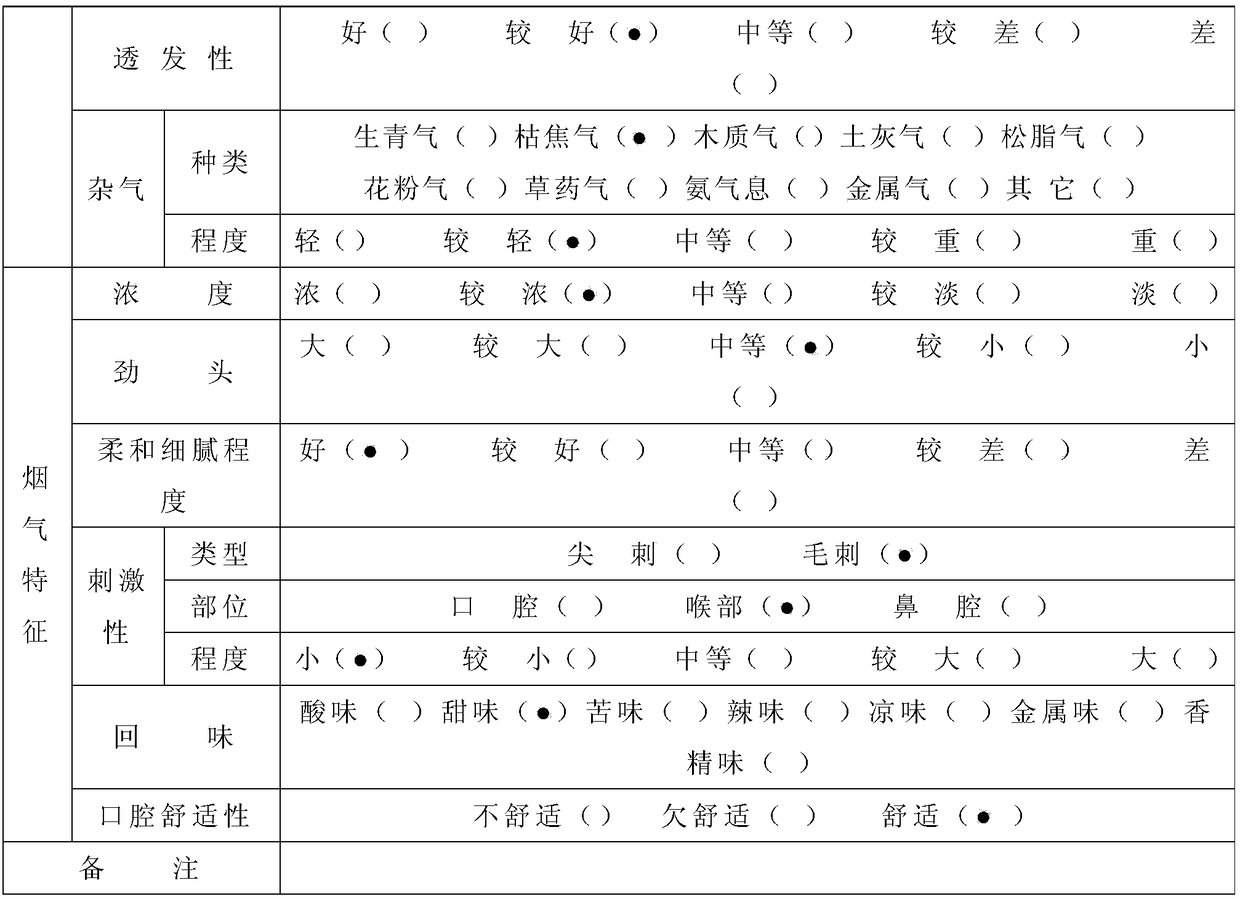

Image

Examples

Embodiment 1

[0028] An essence for improving the mouthfeel of heat-not-burn tobacco provided in Example 1, its preparation method is as follows:

[0029] (1) Raw material production:

[0030] a. After crushing the fresh Luo Han Guo fruit, soak it in 70% ethanol which is 15 times its mass for 5 hours, ultrasonicate for 50 minutes under the condition of ultrasonic power of 40W and temperature of 50°C, cool, filter, and depressurize the filtrate at 50°C Concentrate to a relative density (20°C): 1.1826±0.0080, then you can get the fresh fruit extract of Luo Han Guo, set aside;

[0031] b. add the ethanol of concentration 70% to sour plum according to the ratio of solid-liquid mass ratio 1: 4, under the condition of 70 ℃ heat reflux extraction 1 hour, gained product is through cooling, filtering, and the filtrate is reduced under 60 ℃ condition Concentrate under pressure to a relative density (20°C): 1.2356±0.0080, then the sour plum extract can be obtained for future use;

[0032] (2) Flavor...

Embodiment 2

[0037] An essence for improving the mouthfeel of heat-not-burn tobacco provided in Example 2, the preparation method of which is as follows:

[0038] (1) Raw material production:

[0039] a. After crushing the fresh Luo Han Guo fruit, soak it in 70% ethanol which is 20 times its mass for 8 hours, ultrasonicate for 60 minutes at an ultrasonic power of 60W and a temperature of 70°C, cool, filter, and depressurize the filtrate at 60°C Concentrate to a relative density (20°C): 1.1826±0.0080, then you can get the fresh fruit extract of Luo Han Guo, set aside;

[0040] b. add the ethanol of concentration 70% to sour plum according to the ratio of solid-liquid mass ratio 1: 8, under the condition of 90 ℃ heat reflux extraction 3.5 hours, gained product is through cooling, filtering, and the filtrate is reduced under the condition of 70 ℃; Concentrate under pressure to a relative density (20°C): 1.2356±0.0080, then the sour plum extract can be obtained for future use;

[0041] (2) Fla...

Embodiment 3

[0046] An essence for improving the mouthfeel of heat-not-burn tobacco provided in Example 3, the preparation method of which is as follows:

[0047] (1) Raw material production: a. After crushing the fresh Luo Han Guo fruit, soak it in ethanol with 70% concentration of 18 times its mass for 6 hours, ultrasonic power is 50W, and the temperature is 60 ℃ under the condition of ultrasonic 55min, cooling, filtering, filtrate in Concentrate under reduced pressure at 55°C to a relative density (20°C): 1.1826±0.0080, then you can get the fresh fruit extract of Luo Han Guo, which is ready for use;

[0048] b. add the ethanol of concentration 70% to sour plum according to the ratio of solid-liquid mass ratio 1: 6, under the condition of 80 ℃ heat reflux extraction 2.2 hours, gained product is through cooling, filtering, and the filtrate is reduced under the condition of 65 ℃ Concentrate under pressure to a relative density (20°C): 1.2356±0.0080, then the sour plum extract can be obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com