Organic pit mud for liquor brewing use and preparation technology thereof

A cellar mud and organic technology, applied in the field of wine making, can solve the problems of easy decay of microorganisms, inability to produce good wine, and easy hardening and aging of inorganic pit mud, so as to achieve strong nutrient sustainability, reduce wine making cost input, and rich and diverse bacterial flora Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

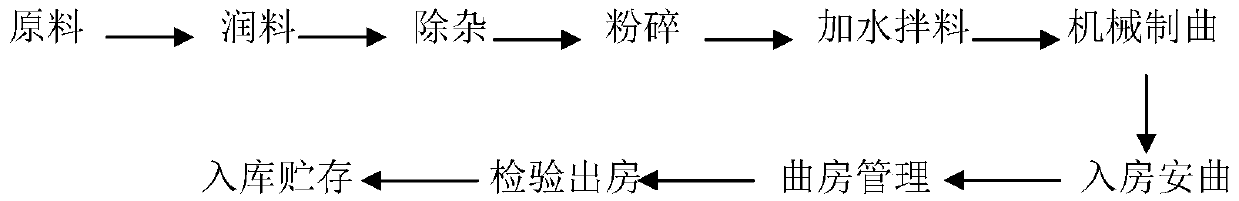

Method used

Image

Examples

Embodiment 1

[0034] 1. Experimental materials and procedures

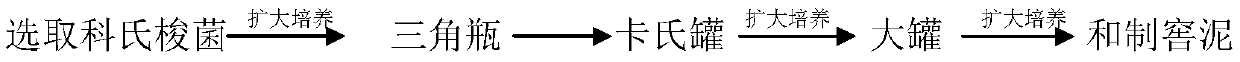

[0035] 1. Make mother liquor

[0036] (1) Raw materials and dosage

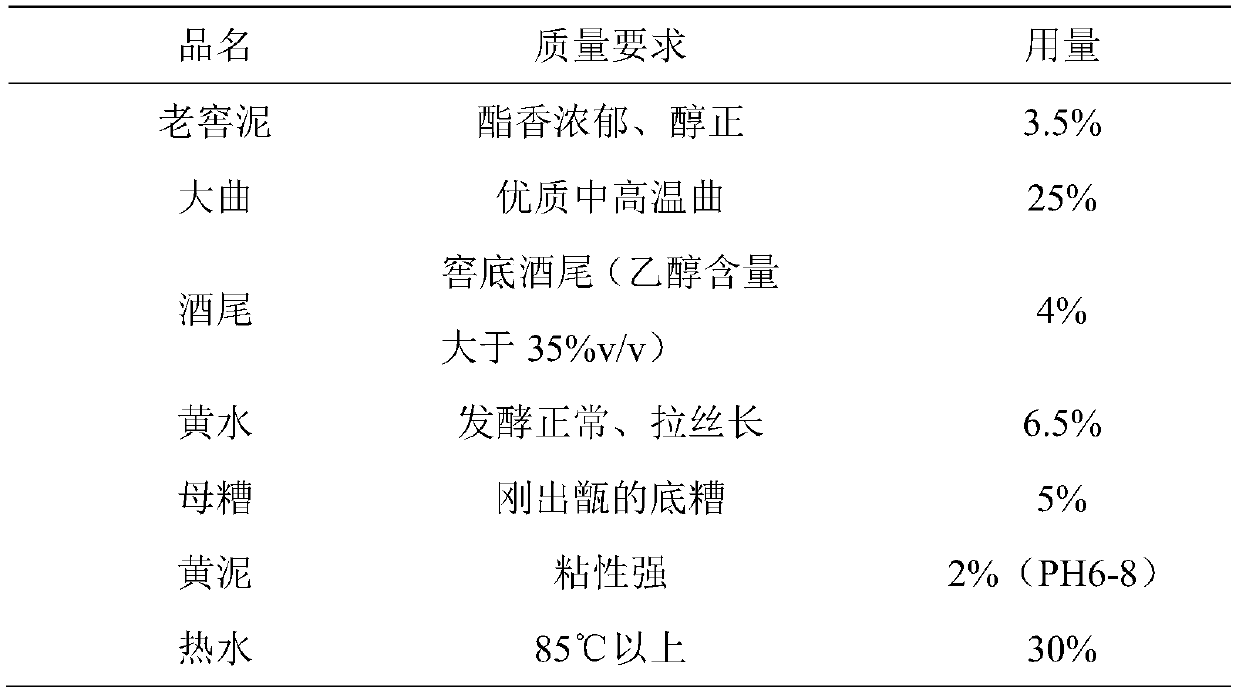

[0037] Table 1 mother liquor raw materials and dosage

[0038]

[0039] (2) Mixing and cultivation

[0040] ① Sterilization in the vat, first crush the dried yellow mud and put it into the vat, then add hot water (20%) above 85°C, stir evenly, seal the altar immediately, keep warm and sterilize. On the second day, continue to heat the water to about half a tank (30%), and adjust the temperature in the tank between 42-45°C.

[0041] ②Prepare the strain liquid: add a small amount of hot water (not lower than 45°C) in a small pail, add the old pit mud, grind it into a slurry, add 8 kg of koji, and mix well. After mixing, keep the temperature in the barrel at about 40°C, slowly pour the cultured and mature bacteria solution into the barrel and stir evenly.

[0042] (3) Add ingredients and mix well

[0043] Add the yellow water, mother's grains, and wine t...

Embodiment 2

[0104] 1. Experimental steps

[0105] 1. Experimental samples

[0106] The organic pit mud of the present application prepared in embodiment 1, the inorganic pit mud commonly used on the market

[0107] 2. Detection of physical and chemical indicators of organic pit mud and inorganic pit mud

[0108] (1) Determination of moisture in fresh samples

[0109] Weigh 15g of the organic pit mud made in Example 1 on the balance, weigh 15g of the common inorganic pit mud on the market, spread it in a low-type weighing dish with constant weight (diameter is 50-60cm), place In a drying oven at 105-110°C, after drying for 6-8 hours, take it out and cover it, put it in a glass drying oven, cool it to room temperature (about 30 minutes) and weigh it, and then calculate according to the following formula:

[0110] Moisture and volatile matter:

[0111] In the formula: W1——weighing bottle plus sample weight before drying (g);

[0112] W2——weigh the bottle and add the sample weight afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com