Blueberry fruit wine brewing method

A technology of black rice tree and black rice, which is applied in the field of wine making, can solve the problems of low utilization rate of black rice tree berries, achieve the effects of reducing the formation of bad metabolites, stable appearance quality, and preventing precipitation in the bottle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

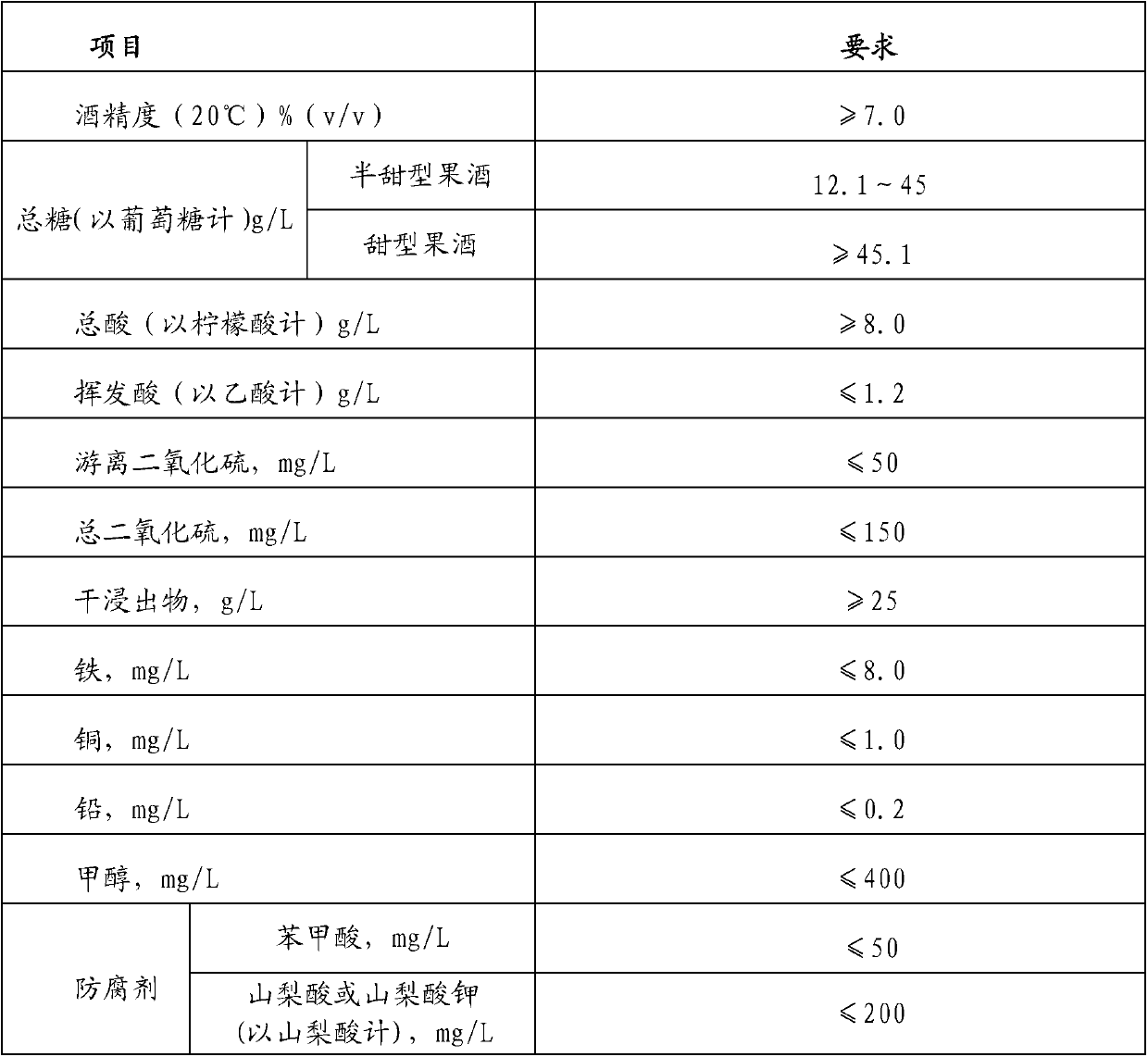

[0034] Embodiment 1 Semi-sweet type Wufanshu fruit wine

[0035] 1) The fruit of the black rice tree is fully mature around November, and immediately after picking it is transported to the processing plant, where the fruit of the black rice tree is cleaned and broken to obtain the black rice tree pulp;

[0036] 2) Fill the stainless steel fermentation tank with carbon dioxide and add sulfur dioxide. The amount of sulfur dioxide added is 50 mg of sulfur dioxide per liter of black rice fruit pulp. Put the black rice fruit pulp obtained in step 1) into the fermenter and heat at 60°C 6 hours;

[0037] 3) Cool down the processed blackberry fruit pulp in step 2) to 40°C, press it, and separate the pomace to obtain blackberry fruit juice. Add pectinase to the blackberry fruit juice. The amount of pectinase added Add 30 mg of pectinase to the juice of black rice tree, and react for 6 hours;

[0038] 4) Determination of reducing sugar, titrable acid and α-amino nitrogen content in th...

Embodiment 2

[0042] Embodiment 2 sweet type Wufanshu fruit wine

[0043] 1) The fruit of the black rice tree is fully mature around November, and immediately after picking it is transported to the processing plant, where the fruit of the black rice tree is washed and crushed to obtain the black rice tree pulp;

[0044] 2) Fill the fermenter with carbon dioxide and add sulfur dioxide. The amount of sulfur dioxide added is 70 mg of sulfur dioxide per liter of black rice fruit pulp. Put the black rice fruit pulp obtained in step 1) into the fermenter and heat at 70°C for 10 Hour;

[0045] 3) Cool down the processed blackberry fruit pulp in step 2) to 40°C, press it, and separate the pomace to obtain blackberry fruit juice. Add pectinase to the blackberry fruit juice. The amount of pectinase added Add 30 mg of pectinase to the juice of black rice tree, and react for 12 hours;

[0046] 4) Measure the content of reducing sugar, titrable acid and α-amino nitrogen in the fruit juice, add the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com