Method for preparing cigarette filter additive from peppermint

A technology for cigarette filter rod and peppermint, which is applied in the fields of preparing cigarette filter rod additives and cigarette filter tip materials, can solve the problems of loss of plant material aroma substances, insufficient natural tobacco aroma, loss of aroma substances and the like, and achieves rich cigarettes. Aroma, rich aroma, effect of enhancing aroma quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

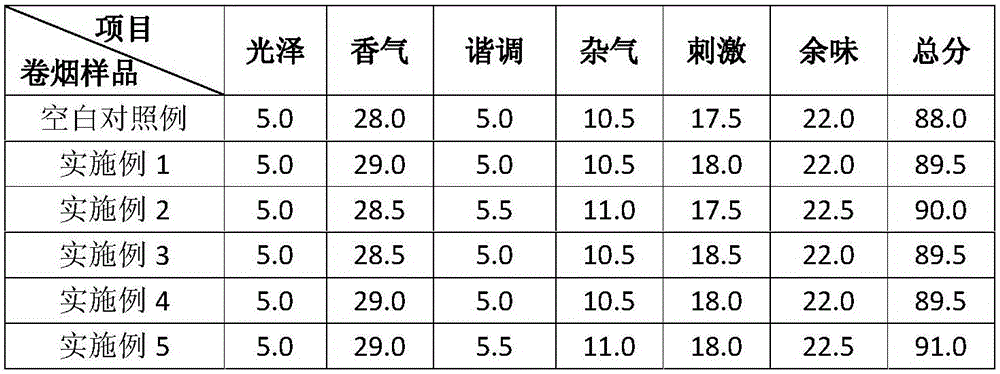

Examples

Embodiment 1

[0033] Embodiment 1: Preparation of peppermint filter stick additive:

[0034]Pre-cool peppermint leaves, K326 firework petals and red tobacco leaves at -20°C for 12 hours, then vacuum freeze-dry peppermint leaves, fireworks petals and red tobacco leaves at a cold trap temperature of -110°C to a moisture content of 5%; use a low-temperature ultrafine pulverizer to pulverize the freeze-dried peppermint leaves, fireworks petals, and tobacco leaves so that the micropowder particles can pass through a 100-mesh sieve; weigh 50 Put 1 kilogram of peppermint leaf powder, 7 kilograms of fireworks petal powder, 18 kilograms of tobacco leaf powder, and 25 kilograms of tobacco pectin powder into a high-speed mixer, and add 3 kilograms of water to the mixer, and then fully stir; use water cooling The type dry granulator extrudes the uniformly mixed material into tablets, and controls the thickness of the tablets at 1.5-2.0mm, and the cooling water temperature of the nip roller is at 30-40°...

Embodiment 2

[0037] Example 1 was repeated, with the following differences: the peppermint leaves, the petals of Honghua Dajinyuan fireworks and the leaves of Dajinyuan were vacuum freeze-dried to a state with a moisture content of 5%. Take by weighing 60 kilograms of peppermint leaf powder, 5 kilograms of fireworks petal powder, 12 kilograms of tobacco leaf powder, 23 kilograms of tobacco pectin powder, and add 2 kilograms of water. Control the thickness of the tablet at 1.8-2.5mm, and the cooling water temperature of the nip roller at 35-45°C. Add the peppermint composite particles obtained in Example 2 to the filter stick tow at a dosage of 1.0 mg / mm.

Embodiment 3

[0039] Example 1 was repeated, with the following differences: peppermint leaves, K326 fireworks petals and tabacum leaves were vacuum freeze-dried to a state with a moisture content of 6%. Weigh 40 kg of peppermint leaf powder, 10 kg of fireworks petal powder, 20 kg of tobacco leaf powder, and 30 kg of tobacco pectin powder, and add 2.5 kg of water to control the thickness of the tablet at 1.5 to 2.0mm. The cooling water temperature is 30-40°C. Add the peppermint composite particles obtained in Example 3 to the filter stick tow at a dosage of 2.0 mg / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com