Tobacco flavor enhancing fragrance essence for heat-not-burn cigarettes as well as preparation method and application thereof

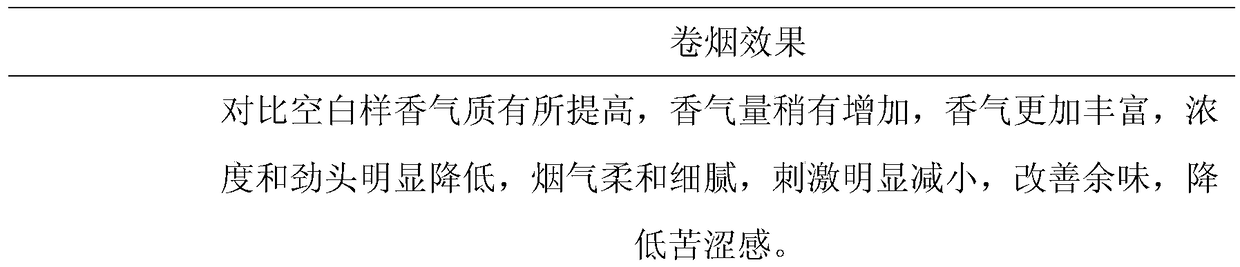

A heat-not-burn and tobacco technology, which is applied in the fields of tobacco, application, and tobacco treatment, can solve problems that affect the smoking experience and enjoyment, large sample differences, differences in aroma, concentration, and taste, and achieve improved experience and Enjoyment, uniform and stable aroma release, comfortable and natural aroma effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

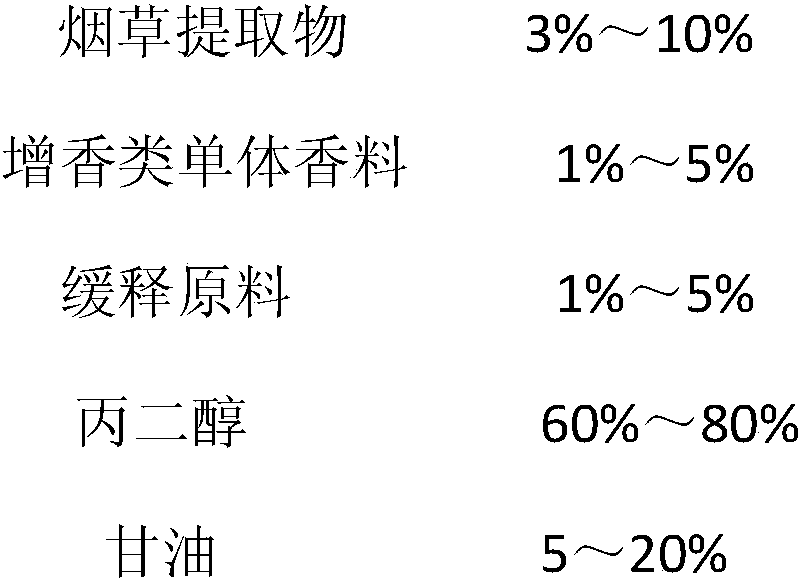

[0026] The tobacco-flavored flavoring essence for heat-not-burn cigarettes described in Example 1 is mixed with the following components in mass percentage: 3% of oriental tobacco molecular distillate, 1% of sun-cured red tobacco molecular distillate, Zimbabwean tobacco extract 4%, sucrose fatty acid ester 2%, fructose 0.2%, macrostigmatrienone 0.3%, turkelenone 0.2%, lactic acid 0.2%, linalool 0.1%, propylene glycol 79%, glycerin 10%;

[0027] Add the above molecular distillate of oriental tobacco, molecular distillate of sun-cured red tobacco, Zimbabwean tobacco extract and propylene glycol into a mixing tank and mix at a frequency of 10-50HZ for 1-2 hours, mix well and set aside, then add all the sucrose fatty acids Esters, fructose, macrostigmatrienone, turkenone, lactic acid, and linalool are fully mixed for later use, and finally glycerin is added to continue stirring and mixing, and the clarified liquid is obtained by filtering through a 200-400 mesh filter to obtain hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com