Efficient Fenton-like technology beneficial to repeated reaction

A Fenton-like process technology, applied in the field of high-efficiency Fenton-like processes, can solve problems such as catalyst recovery, catalyst loss, and wear and tear of catalytic treatment equipment, and achieve the effects of reducing processing costs, stable properties, and reducing reaction operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

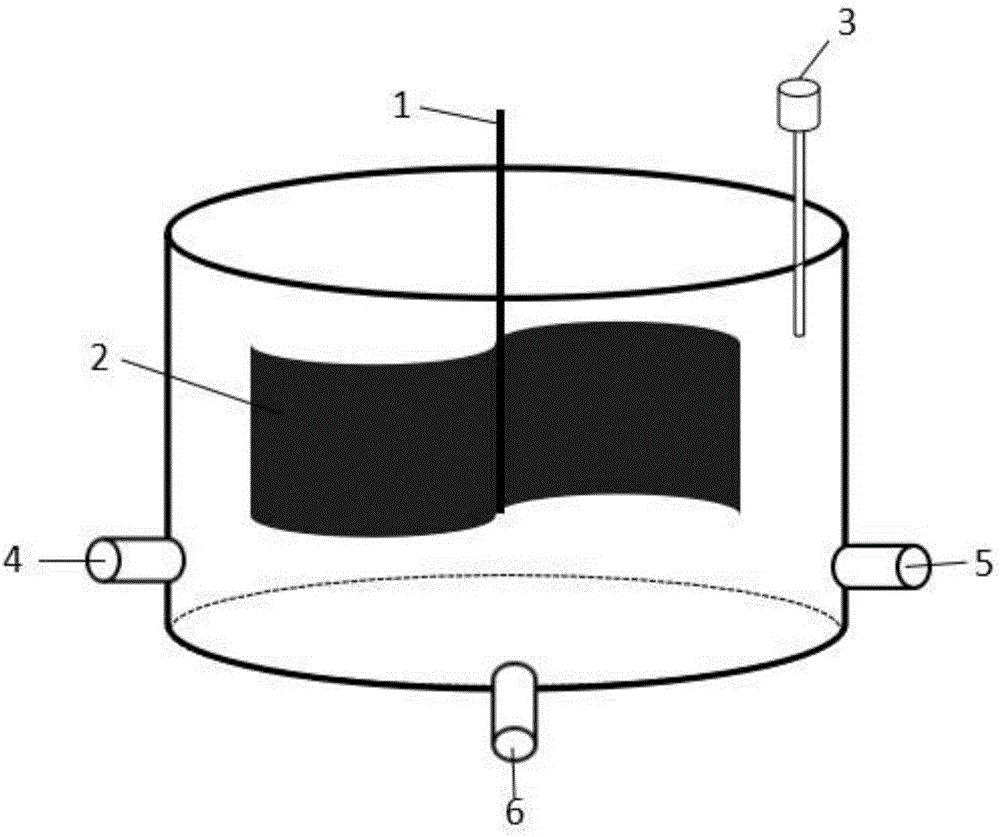

Image

Examples

preparation example Construction

[0036] 1. Preparation of catalyst particles: Put the powders of alumina, magnesia, and titanium dioxide into a ball mill at a mass ratio of 1:1:1, grind and mix them, put them in a muffle furnace at 800-1000℃ for 4-8h, and intercept 100 meshes Particles between ~200 mesh.

[0037] 2. Catalyst thermal spraying: The catalyst particles are sprayed on the surface of the turbine by thermal spraying technology. The spraying temperature is set to 350-500℃, the spraying pressure is set to 0.6-0.8MPa, the spraying distance is set to 15-25mm, and the powder feeding amount is set to 5. -20g / min.

[0038] 3. Fenton-like process: Put the turbine sprayed with catalyst particles into the container, add hydrogen peroxide (30%) in a ratio of 1:100 to 1:200 wastewater (volume ratio), and add hydrogen peroxide evenly during the reaction. The rotation speed is set to 100~180rpm, and the processing time of similar Fenton process is 1~2h.

[0039] 4. Determination of water quality indicators: To determi...

Embodiment 1

[0042] 1. Put the powders of alumina, magnesia, and titanium dioxide into a ball mill at a mass ratio of 1:1:1, grind and mix them, put them in a muffle furnace at 800°C for 6 hours, and intercept particles between 100 mesh and 200 mesh. The catalyst particles are sprayed on the surface of the turbine by thermal spraying technology, the spraying temperature is set to 400℃, the spraying pressure is set to 0.7MPa, the spraying distance is set to 20mm, and the powder feeding rate is set to 12g / min.

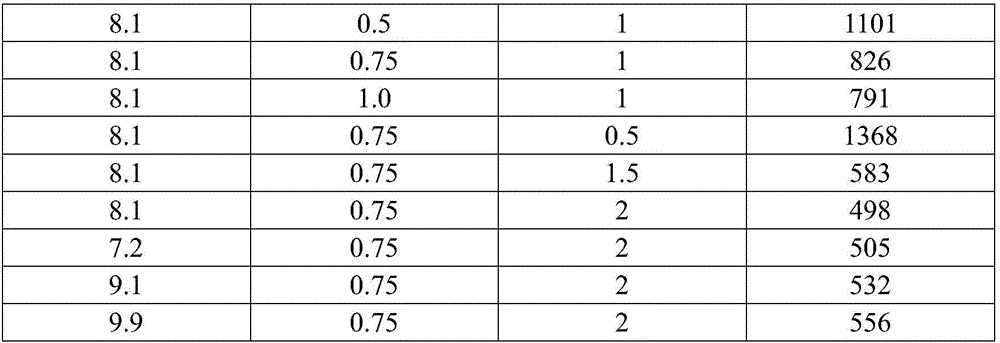

[0043] 2. The desulfurization wastewater taken from Huadian Laizhou Power Plant has a conductivity of 23.1mS / cm, an initial pH of 8.1, and an initial TOC value of 2205. The desulfurization wastewater is introduced into the reaction vessel, 30% hydrogen peroxide is evenly added during the reaction, and the turbine speed is set to 180 rpm.

[0044] 3. The reaction time is set to 2h. After the reaction is over, the supernatant is taken for analysis.

[0045] Water quality determination: TOC a...

Embodiment 2

[0050] 1. The preparation steps are the same as in Example 1.

[0051] 2. The domestic wastewater taken from Huadian Laizhou Power Plant has a conductivity of 4.11mS / cm, an initial pH of 8.6, and an initial TOC value of 1871.

[0052] 3. The processing and analysis process are the same as in Example 1. The results of water quality measurement are shown in Table 2.

[0053] Table 2 Water quality measurement results of Example 2

[0054]

[0055] The invention mainly realizes the rapid removal of organic matter in high-salt wastewater by constructing equipment that can efficiently improve the Fenton-like effect and an advanced Fenton-like process. The process loads the catalyst on the surface of the turbine, which not only can efficiently improve hydrogen peroxide The function of oxidation ability, and can avoid the friction between the catalyst and the reactor wall, prevent the catalyst from being destroyed, and maintain the catalyst activity of the catalyst. At the same time, the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com