Keyboard and manufacturing method thereof

A manufacturing method and keyboard technology, applied in the direction of electrical components, electrical switches, circuits, etc., can solve problems such as unfavorable mass production, low practicability, complex manufacturing process, etc., achieve good metallic luster effect, and simplify the effect of spraying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

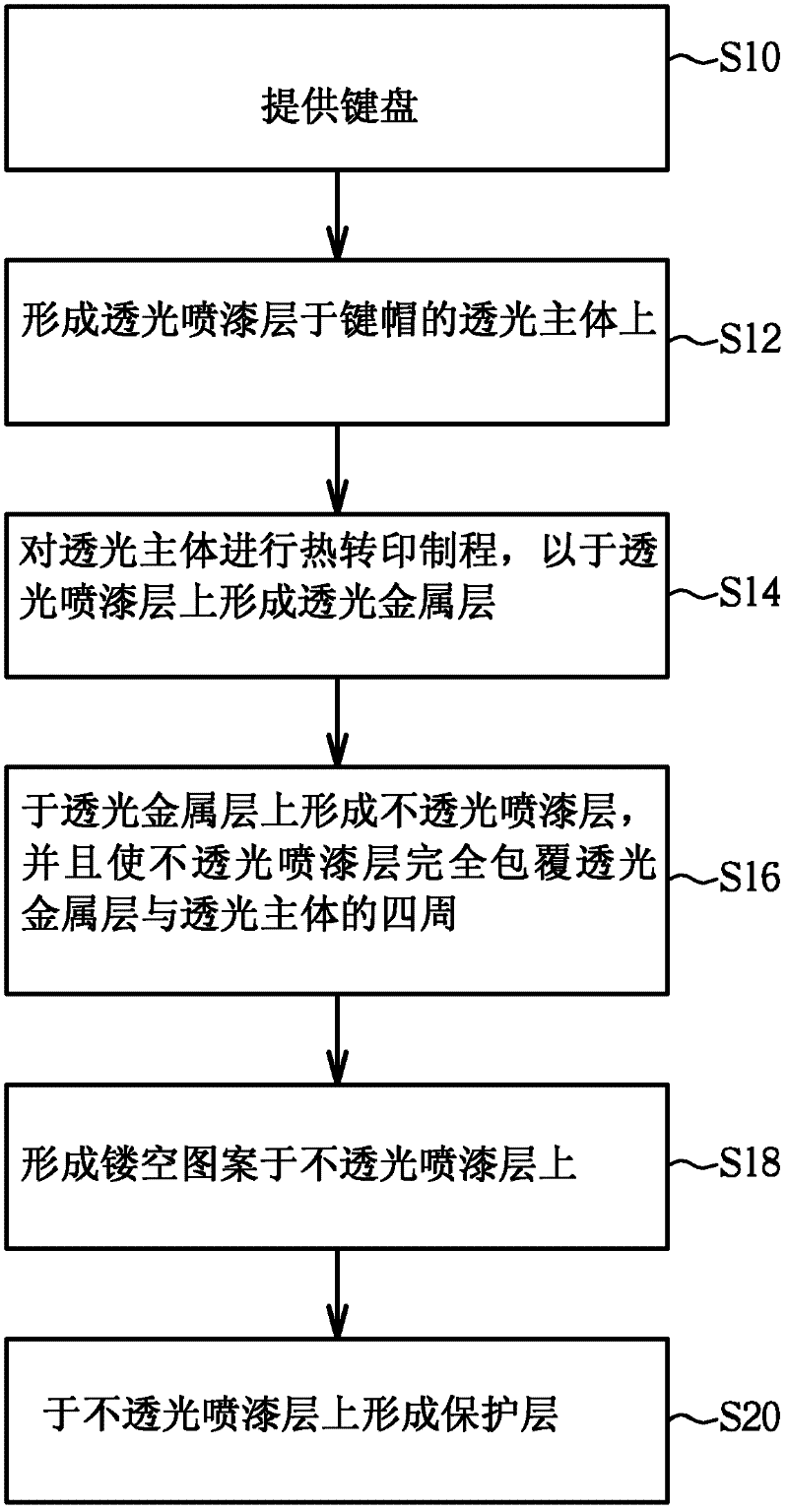

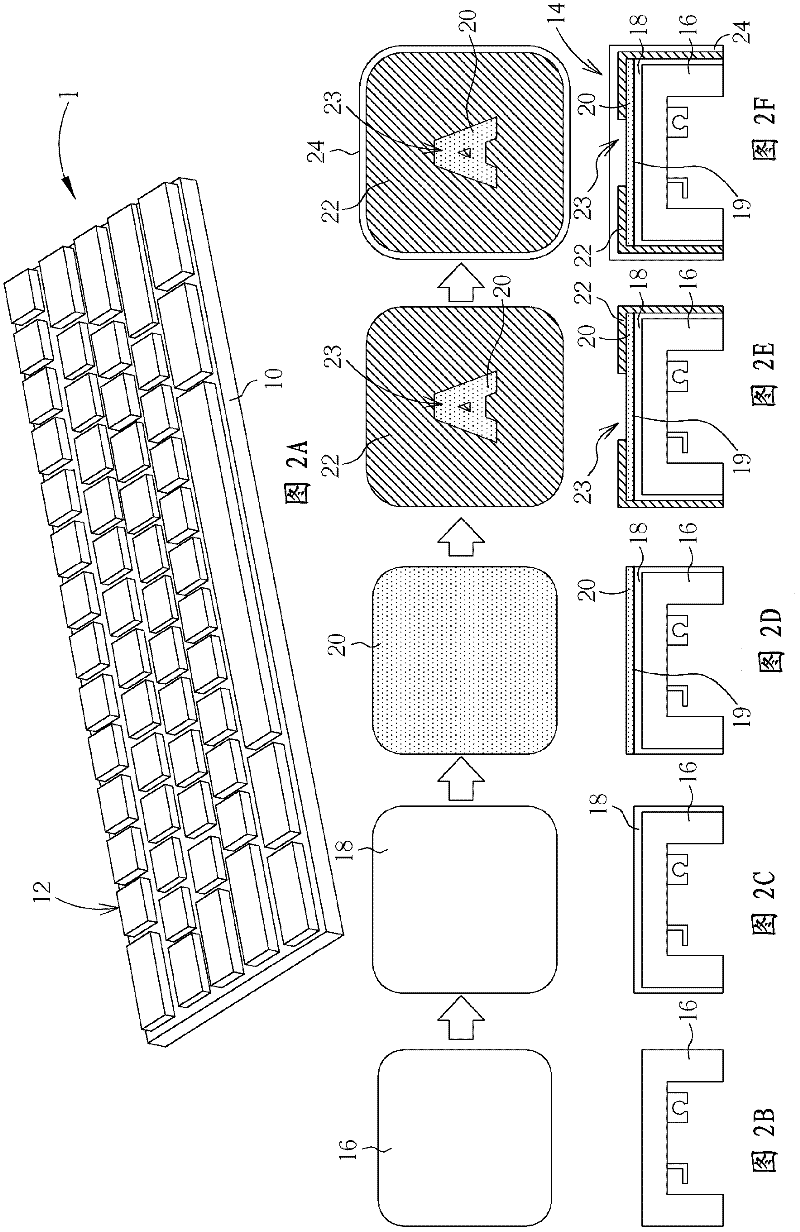

[0033] see figure 1 as well as Figure 2A to Figure 2F , figure 1 It is a flowchart of a keyboard manufacturing method according to an embodiment of the present invention, Figure 2A to Figure 2F for matching figure 1 Schematic diagram of the process. For the convenience of explanation, Figure 2A presented as a stereogram, while Figure 2B to Figure 2F Then it is presented in a sectional view supplemented with a top view and only a single keycap is shown.

[0034] First, step S10 is performed to provide keyboard 1, such as Figure 2A shown. In this embodiment, the keyboard 1 includes a base plate 10 and a plurality of keys 12, wherein the keys 12 are arranged on the base plate 10, and the keys 12 include a keycap 14, and the keycap 14 includes a light-transmitting body 16, a light-transmitting paint layer 18, a transparent Light metal layer 20, at least one opaque spray paint layer 22 (in Figure 2F Shown in one), and protective layer 24. Cooperate with single key c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com