Preparation method of nickel, chromium, boron, silicon and niobium alloy abrasion-resistant coating

A nickel-chromium borosilicate and wear-resistant coating technology, which is applied in metal material coating process, coating, fusion spraying, etc., can solve the problem of decreased corrosion performance and fatigue performance of the coating, high brittleness of the hard phase, and increased cost and other issues, to achieve the effect of improving hardness and wear resistance, excellent wear resistance, and reducing heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

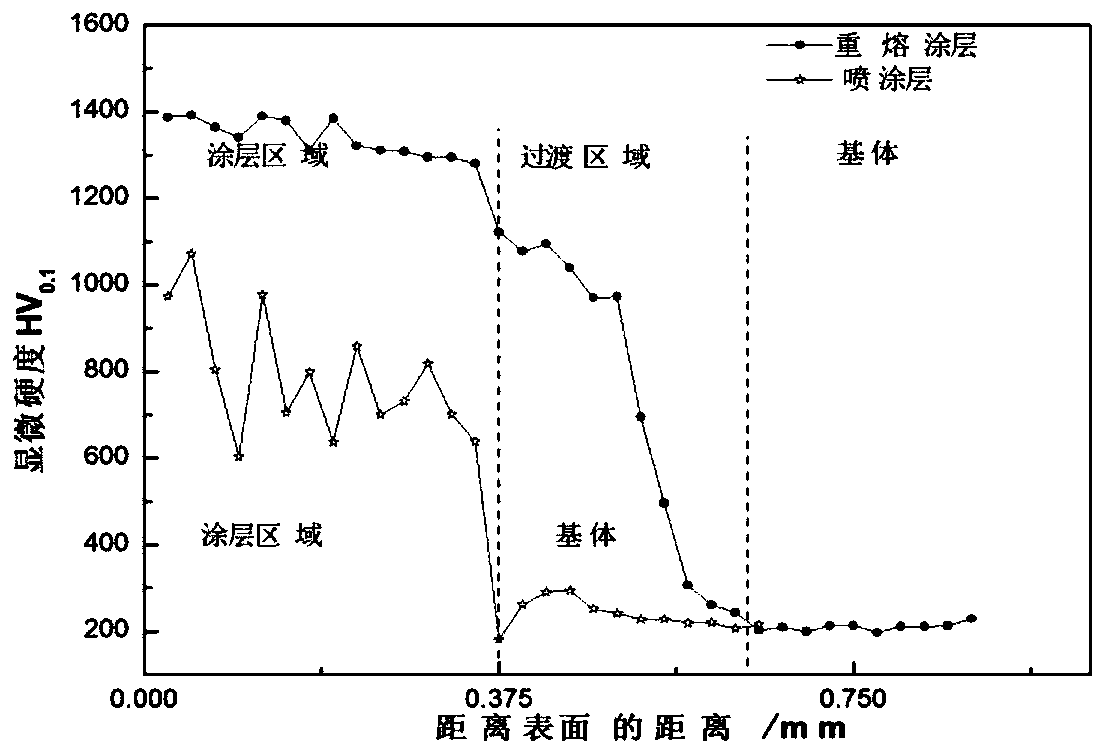

[0035] The present embodiment 1 adopts nickel chromium borosilicate niobium (NiCrBSiNb) powder according to the composition ratio in the table below, the purity is 99% elemental Ni, Cr, Mn, Nb, and purity is 99.99% elemental B, Si, mix Afterwards, alloying treatment is carried out by high-energy ball milling to obtain alloy powder, that is, nickel chromium borosilicate niobium (NiCrBSiNb) powder with a thickness of 25-50 μm.

[0036] Table 1 Chemical composition of NiCrBSiNb (mass fraction, %)

[0037]

[0038] The purity of Ni, Cr, Mn and Nb is 99%, and the purity of B and Si is 99.99%.

[0039] The main steps include: quenching and tempering the 45 steel substrate → sandblasting the 45 steel substrate → feeding the arcing ion gas → powering the spraying equipment → starting the arc of the plasma spray gun → feeding the metal self-fluxing alloy for spraying into the plasma stream The powder is sprayed on the surface of the workpiece to form a nickel-chromium borosilicate ...

Embodiment 2

[0058] In Example 2, nickel chromium borosilicate niobium (NiCrBSiNb) powder is used, and nickel chromium borosilicate niobium (NiCrBSiNb) powder with a thickness of 25-50 μm is selected. Change the content of Cr, B, Si, Mn in the coating, the composition of this powder is shown in Table 3.

[0059] Table 3 Chemical composition of NiCrBSiNb (mass fraction, %)

[0060]

[0061] Other steps are the same as in Example 1. The resulting coating properties are close to Example 1.

Embodiment 3

[0063] In Example 3, nickel chromium borosilicate niobium (NiCrBSiNb) powder is used, and nickel chromium borosilicate niobium (NiCrBSiNb) powder with a thickness of 25-50 μm is selected. Change the content of Cr, B, Si, Mn in the coating, the composition of this powder is shown in Table 4.

[0064] Table 4 Chemical composition of NiCrBSiNb (mass fraction, %)

[0065]

[0066] Other steps are the same as in Example 1. The resulting coating properties are close to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Rockwell hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com