Preparation method for IC10 alloy low-pressure-turbine guide vane thermal barrier coating

A technology of thermal barrier coating and guide vane, which is applied in metal material coating process, coating, fusion spraying and other directions, can solve the problem of inability to meet the service requirements of aero-engine heterosexual blades, and achieves a simple, feasible and good spraying process method. The effect of corrosion resistance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

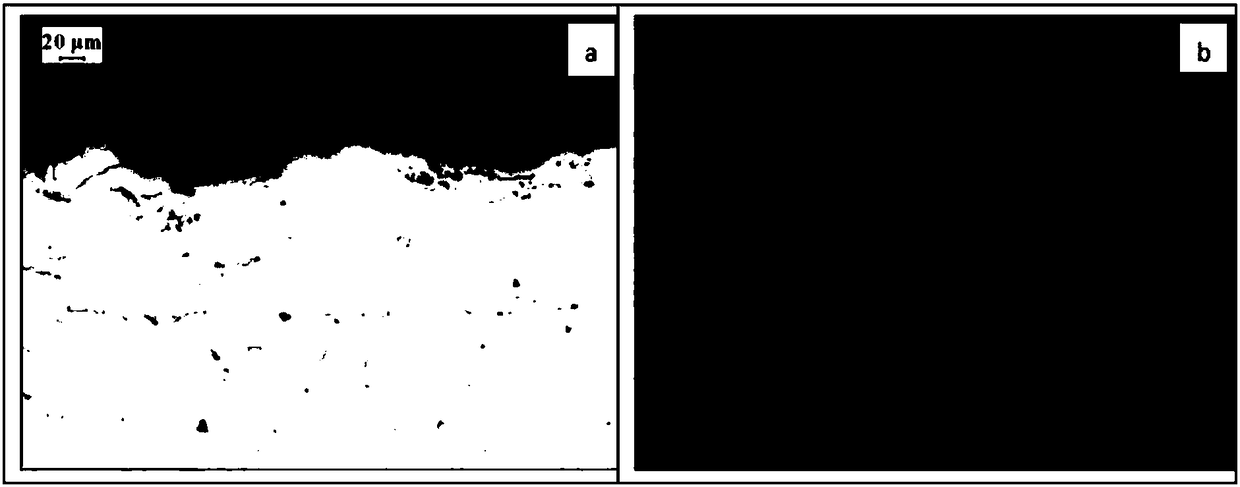

Image

Examples

Embodiment 1

[0028] Embodiment 1: The part alloy grade is IC10 alloy

[0029] In this example, it is used for the preparation method of IC10 alloy low-guide vane thermal barrier coating, and the specific steps are as follows:

[0030] Step 1: Degrease the surface of the parts, use acetone or gasoline to wipe the sprayed area of the parts to remove oil and debris;

[0031] Step 2: Use pressure-sensitive tape to protect the non-sprayed area before sandblasting;

[0032] Step 3: Roughen the surface of the parts, using a press-in sand blower, 40 mesh white corundum sand to treat the area to be sprayed, and the gas pressure is 0.2MPa;

[0033] Step 4: Supersonic spray NiCrAlYSi bottom layer (the nominal composition of the bottom layer is Ni-20Cr-10Al-0.8Y-1.2Si) on the parts to be sprayed. The specific process parameters are: oxygen flow 825SCFH, current 800A, kerosene flow 6.4GPH, send Powder machine pressure 3.5bar, powder feeding rate 40g / min, spraying distance 350mm;

[0034] Step 5: C...

Embodiment 2

[0036] Embodiment 2: The part alloy grade is IC10 alloy

[0037] In this example, it is used for the preparation method of IC10 alloy low-guide vane thermal barrier coating, and the specific steps are as follows:

[0038] Step 1: Degrease the surface of the parts, use acetone or gasoline to wipe the sprayed area of the parts to remove oil and debris;

[0039] Step 2: Use pressure-sensitive tape to protect the non-sprayed area before sandblasting;

[0040] Step 3: Roughen the surface of the parts, using a press-in sand blower, 60 mesh white corundum sand to treat the area to be sprayed, and the gas pressure is 0.3MPa;

[0041] Step 4: Supersonic spray NiCrAlYSi bottom layer (the nominal composition of the bottom layer is Ni-20Cr-10Al-0.8Y-1.2Si) on the parts to be sprayed. The specific process parameters are: oxygen flow 450SCFH, current 750A, kerosene flow 3.3GPH, send Powder machine pressure 2bar, powder feeding rate 25g / min, spraying distance 300mm;

[0042] Step 5: Carry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com