High-flowability and high-brightness heat conduction nylon composite material and preparation method thereof

A nylon composite material and high-flow technology, applied in the field of nylon composite materials, can solve problems such as heat resistance, poor fluidity, and inability to mix colors, and achieve the effects of improving thermal conductivity, improving dispersion, and improving fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

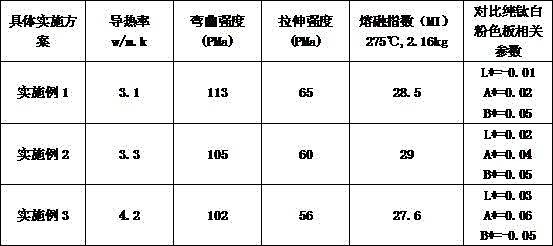

Examples

Embodiment 1

[0018] In terms of mass fraction, weigh the following raw materials: 660 parts of PA660 with a relative viscosity of 2.4, 40 parts of PA6640 with a relative viscosity of 2.4, 0.3 parts of nano-silicon oxide, 20 parts of spherical aluminum nitride with a diameter of 10 μm, and whisker aluminum nitride with an aspect ratio of 20 20 parts, 0.3 parts of antioxidant 1098 and 168 compound, 2 parts of monoalkoxy pyrophospholipid titanate coupling agent, 3 parts of EBS and oxidized polyethylene, 28 parts of isopropanol;

[0019] Mix and stir 2 parts of the monoalkoxy pyrophospholipid titanate coupling agent with 28 parts of isopropanol, and spray one-thirtieth of the obtained mixed solution onto the nano-silicon oxide stirred at a low speed, and spray After completion, stir again at a high speed, and finally put it into an oven with a set temperature of 95°C. After the solvent evaporates, the treated nano-nano silicon oxide is obtained;

[0020] Spray one-half of the remaining mixed s...

Embodiment 2

[0024] According to the mass fraction, weigh the following raw materials: PA650 parts with a relative viscosity of 2.4, PA6650 parts with a relative viscosity of 2.4, 0.4 parts of nano-silicon oxide, 30 parts of spherical aluminum nitride of 10 μm, whisker aluminum nitride with an aspect ratio of 30 20 parts, 0.3 parts of antioxidant 1098 and 168 compound, 3 parts of monoalkoxy pyrophosphatidyl titanate coupling agent, 3.5 parts of EBS and oxidized polyethylene compound, 47 parts of isopropanol;

[0025] Mix and stir 2.5 parts of the monoalkoxy pyrophospholipid titanate coupling agent with 40 parts of isopropanol solvent, and spray one-fiftieth of the resulting mixed solution onto the nano silicon oxide stirred at a low speed, After the spraying is completed, stir again at a high speed, and finally put it into an oven with a set temperature of 95°C. After the solvent evaporates, the treated nano-nano silicon oxide is obtained;

[0026] Spray three-fifths of the remaining mixed...

Embodiment 3

[0030] According to the mass fraction, the following raw materials were weighed: 100 parts of PA66 with a relative viscosity of 2.4, 0.8 parts of nano-silicon oxide, 40 parts of spherical aluminum nitride of 10 μm, 20 parts of whisker aluminum nitride with an aspect ratio of 30, and 1098 parts of antioxidant Compound 0.6 with 168, 4 parts of monoalkoxy pyrophospholipid titanate coupling agent, 4 parts of EBS and oxidized polyethylene, 56 parts of isopropanol

[0031] Mix and stir 4 parts of the surface treatment agent and 56 parts of ethanol solvent, spray one-thirtieth of the obtained mixed solution onto the nano silicon oxide stirred at a low speed, after the spraying is completed, stir at a high speed, and finally put In an oven set at a temperature of 95°C, after the solvent evaporates, the treated nano-nano silicon oxide is obtained;

[0032] Spray two-thirds of the remaining mixed solution above on the spherical aluminum nitride and the other third on the whisker-type al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com