Ampoule bottle embossed printer

An ampoule bottle and printer technology, which is used in typewriters, printing devices, printing and other directions, can solve problems such as unclear handwriting and single color, and achieve the effect of ensuring clarity, improving printing efficiency, and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

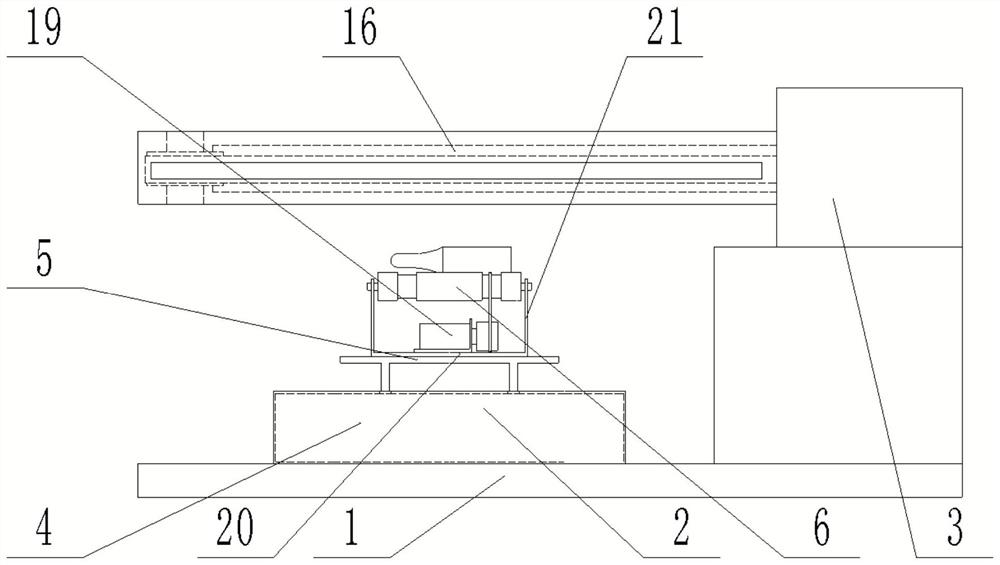

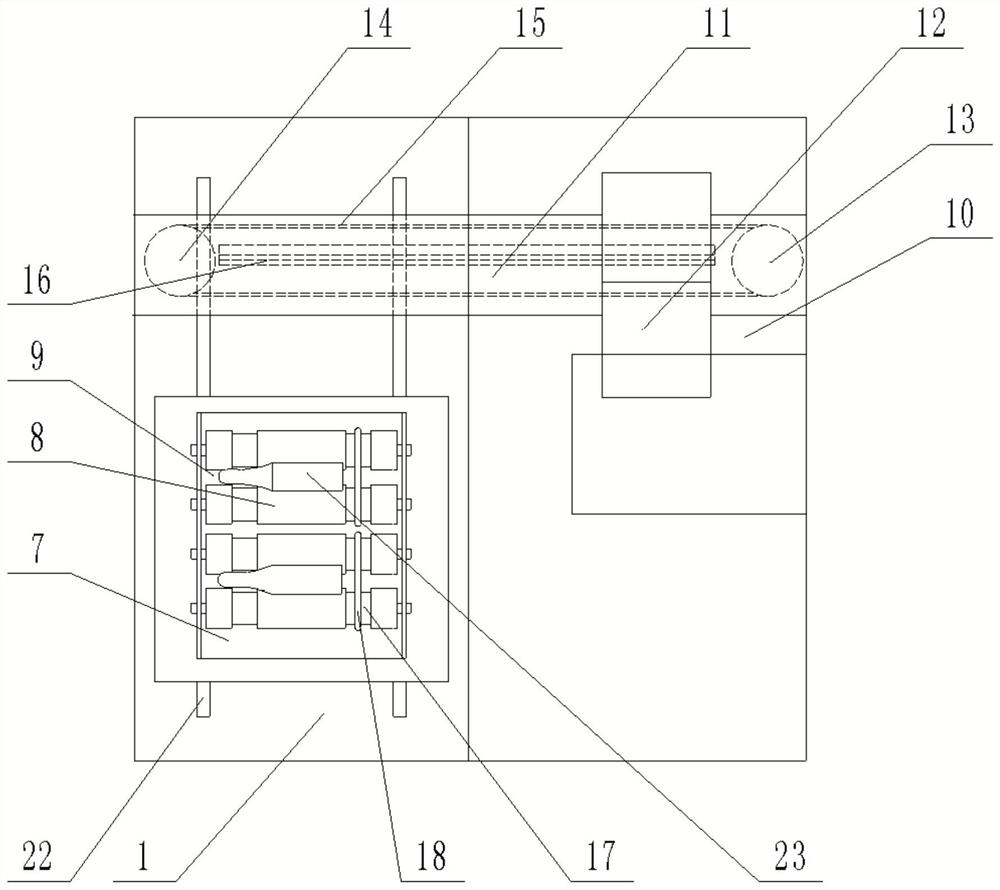

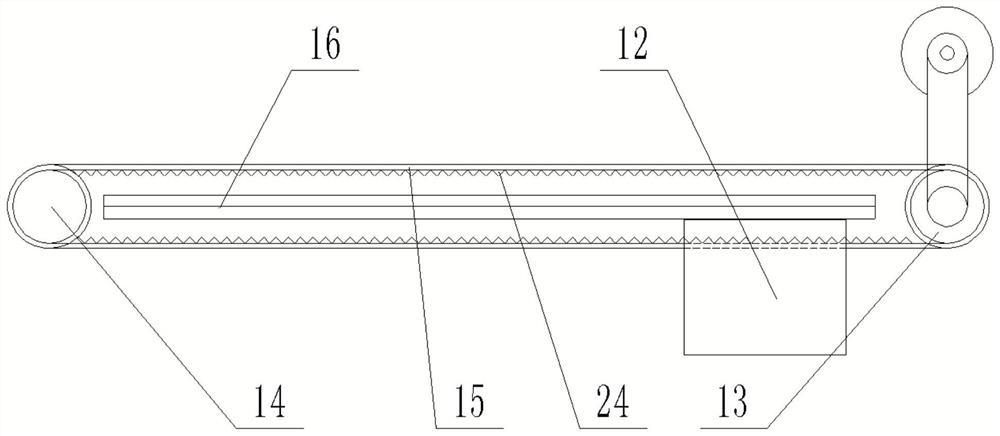

Embodiment 1

[0026] Such as Figure 1-4 As shown, an ampoule embossing printer includes a frame 1 on which a rotary translation processing mechanism 2 and a reciprocating translation printing mechanism 3 are installed; the rotary translation processing mechanism includes a fixed seat 4 on which a Processing platform 5, the upper end surface of the fixed seat is provided with a chute 22 along the translation direction, the lower end surface of the processing platform is equipped with a slider, the slider extends into the chute, and the translation drive for driving the slider to move along the chute is installed in the fixed seat. The motor, the processing platform 5 is equipped with an ampoule support mechanism 6 for placing ampoules 23, the ampoule support mechanism 6 includes a fixed frame 7, and two support rollers 8 are installed on the fixed frame 7 for side by side rotation, and the fixed frame adopts an integrally formed The steel plate, the fixed frame includes a bottom plate 20, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com