Brewing instant pea meal

A pea flour and brewing technology, applied in the field of brewing instant pea flour, can solve the problems affecting the degree of gelatinization, transparency and gelatinization characteristics of pea flour, taste of instant pea flour, influence on color, etc. Delicate taste and good color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

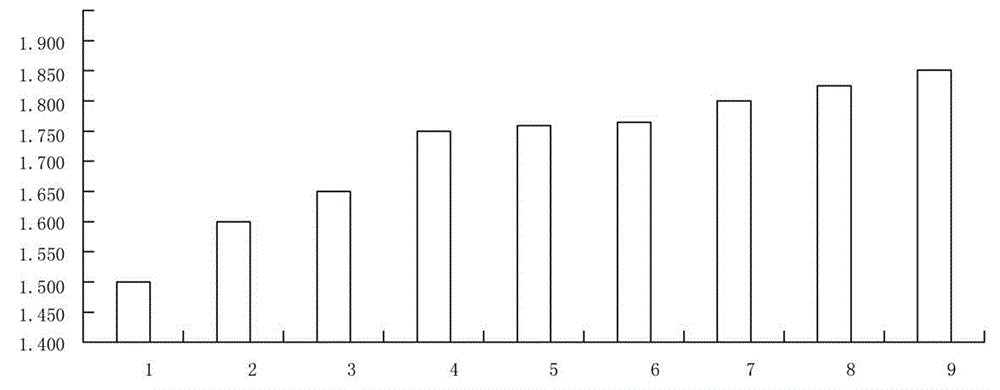

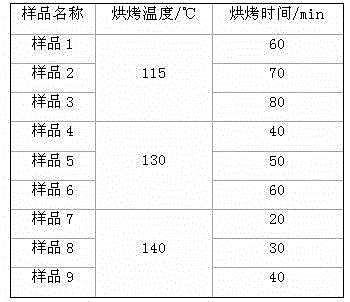

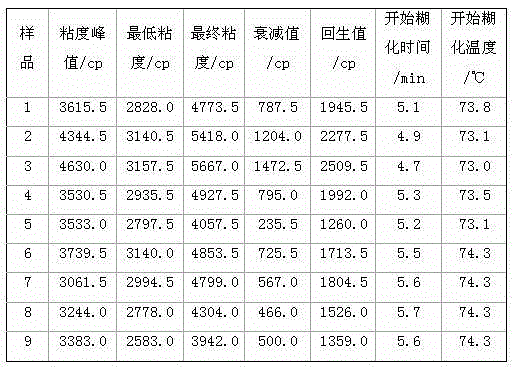

Image

Examples

Embodiment 1

[0016] A kind of ready-to-eat pea powder prepared by the following method: first, select peas with plump grains, no moth-eaten, and no mildew, remove impurities, and wash for use; then, bake the washed peas at 130°C Bake at the baking temperature for 50 minutes; then take the baked peas, soak them in lye until the peas fully absorb water and swell, then peel and grind to obtain pea slurry; then take the pea slurry for spray drying, crushing, and sieve , to prepare ready-to-use pea powder; finally take ready-to-use pea powder, lotus root powder and mung bean powder in proportion, and mix them evenly to obtain instant pea powder; wherein, the weight of the lotus root powder accounts for 20% of the weight of the instant pea powder , the weight of the mung bean powder accounts for 10% of the instant pea powder weight.

[0017] The instant pea powder of this example, through the gelatinization properties, thermodynamic properties, and transparency measurement methods commonly used ...

Embodiment 2

[0019] The difference between this embodiment and Example 1 is that the baking temperature is 125°C and the baking time is 45 minutes; the weight of the lotus root powder accounts for 10% of the weight of the instant pea powder, and the weight of the mung bean powder accounts for 10% of the weight of the instant pea powder. 5% of the instant pea flour weight.

[0020] The instant pea powder of this example, through the gelatinization properties, thermodynamic properties, and transparency measurement methods commonly used in the field, has a final viscosity value of 4250.5 / cp, an attenuation value of 250.5 / cp, and a retrogradation value of 1502.0 / cp.

Embodiment 3

[0022] The difference between this embodiment and Example 1 is that the baking temperature is 135°C and the baking time is 55 minutes; the weight of the lotus root powder accounts for 30% of the weight of the instant pea powder, and the weight of the mung bean powder accounts for 30% of the weight of the instant pea powder. 15% of the instant pea flour weight.

[0023] The instant pea powder of this example, through the gelatinization properties, thermodynamic properties, and transparency measurement methods commonly used in the field, has a final viscosity value of 4310.5 / cp, an attenuation value of 263.5 / cp, and a retrogradation value of 1550.0 / cp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com