Colored photocatalysis fibers and preparation method thereof

A colored fiber, colored light technology, applied in the field of photocatalytic materials, can solve the problem of single color of catalytic functional textiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing colored photocatalytic fibers, comprising the following steps:

[0022] Mix the polyester polymer, color masterbatch and composite photocatalyst evenly for spinning to obtain colored fiber precursors;

[0023] The composite photocatalyst inside the colored fiber precursor is exposed to obtain the colored photocatalytic fiber.

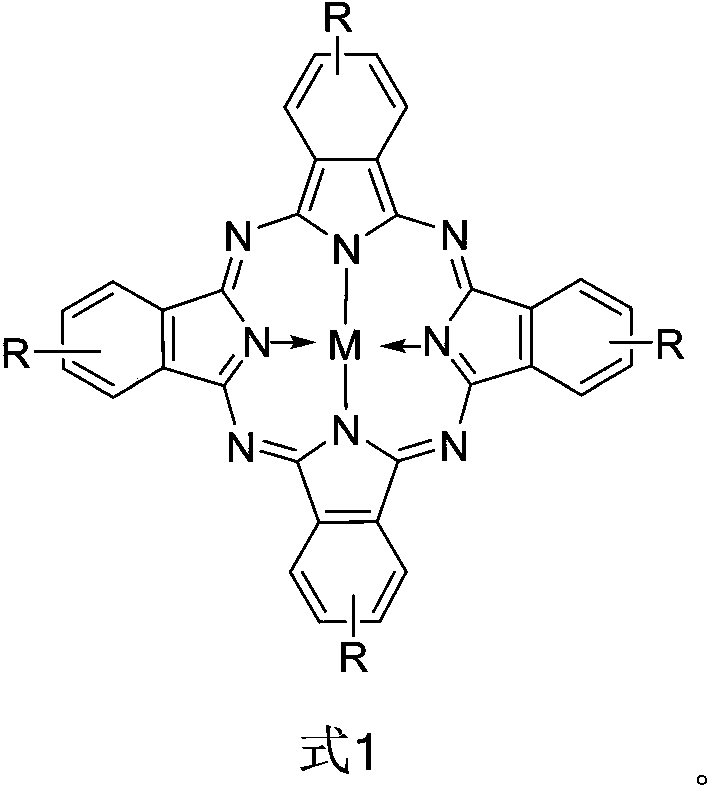

[0024] In the invention, the polyester polymer, color masterbatch and composite photocatalyst are uniformly mixed and spun to obtain colored fiber precursors. In the present invention, the polyester polymer is preferably polyethylene terephthalate, polypropylene terephthalate, polybutylene terephthalate, polyethylene naphthalate , polybutylene succinate, polylactic acid, polyester elastomer and polyglycolide, a mixture of one or more substances or a copolymer of several substances, more preferably one, two, three Mixtures of one, four, five, six, seven or eight substances or copolymers of one, two, ...

Embodiment 1

[0086] Take by weighing 82 parts of polyethylene terephthalate, 3 parts of yellow masterbatch and 15 parts of composite photocatalyst (85% TiO 2 with 15% g-C 3 N 4 ), the three are mixed evenly and melt-spun to obtain colored fiber precursors, the diameter of the colored fiber precursors is 20 μm.

[0087] Then take 100 parts of colored fiber precursors and join in the alkali reduction treatment solution to process 60min, the bath ratio of the alkali reduction treatment is 1:50, and the concentration of sodium hydroxide in the alkali reduction treatment solution is 5g / L, the concentration of the accelerator cetyltrimethylammonium bromide is 0.4g / L, and the water temperature is 80°C. Then it was washed with water until it became neutral, and placed in an oven at 60°C to dry flatly to obtain colored photocatalytic fibers. Weigh its quality, calculate its alkali reduction rate of 15%.

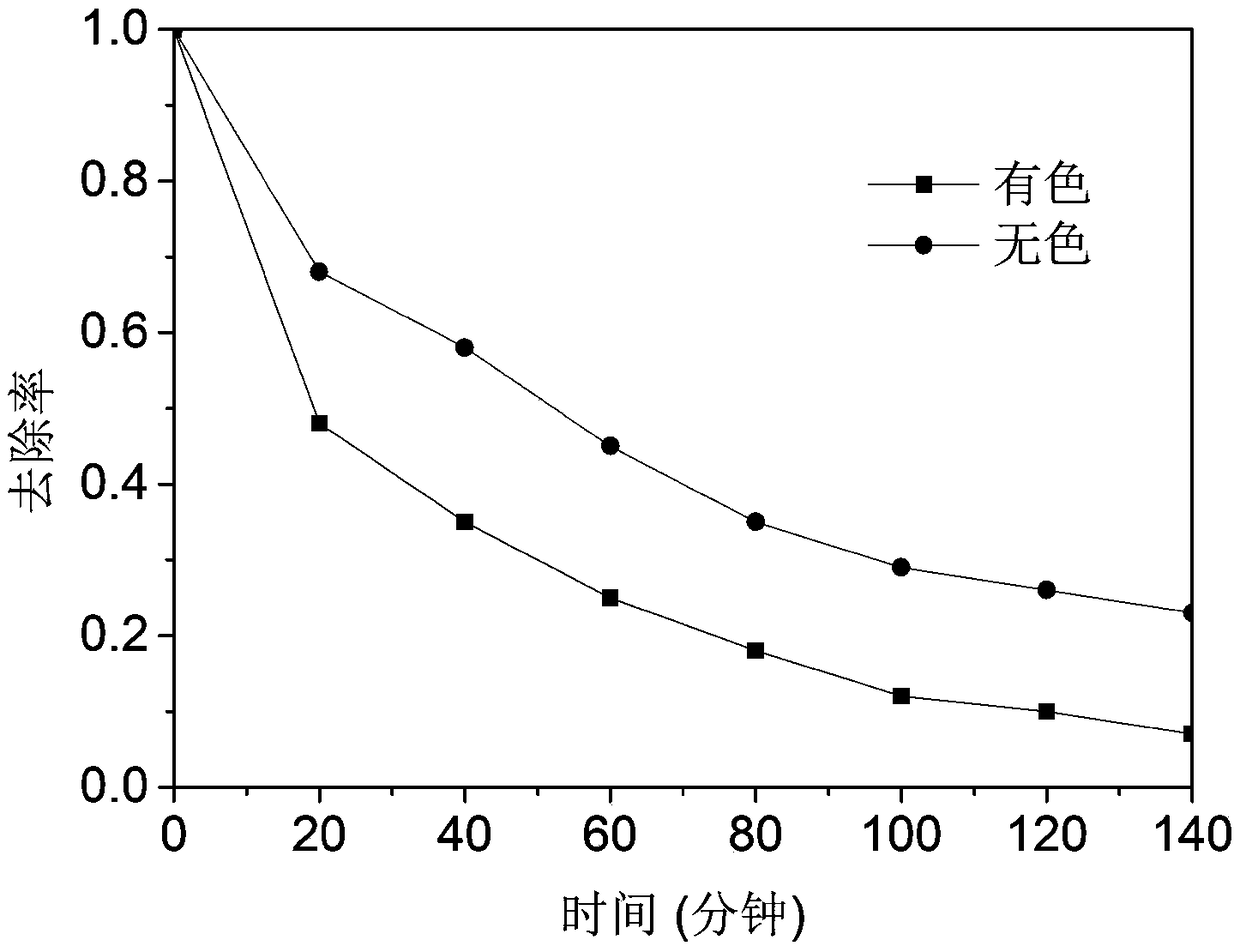

[0088] Add 40mg of the colored photocatalytic fiber obtained in this example to 30mL with...

Embodiment 2

[0090] Take by weighing 87 parts of polytrimethylene terephthalate, 5 parts of blue masterbatch and 8 parts of composite photocatalyst (88% TiO 2 , 10% g-C 3 N 4 and 2% graphene), the three are mixed evenly, and melt-spun to obtain a colored fiber precursor, and the diameter of the colored fiber precursor is 24 μm.

[0091] Then take 100 parts of colored fiber precursors and join in the alkali reduction treatment solution to process 70min, the bath ratio of the alkali reduction treatment is 1:50, and the concentration of sodium hydroxide in the alkali reduction treatment solution is 10g / L, the concentration of the accelerator octadecyl dimethyl hydroxyethyl ammonium nitrate is 0.4g / L, and the water temperature is 80°C. Then it was washed with water until it became neutral, and placed in an oven at 60°C to dry flatly to obtain colored photocatalytic fibers. Weigh its quality and calculate its alkali reduction rate of 20%.

[0092] The present invention detects the colored ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com