Adsorbent with photocatalytic activity, and preparation method and application thereof

A technology of photocatalytic activity and adsorbent, which is applied in the field of adsorption and catalysis, and can solve the problems of low titanium dioxide loading and poor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing an adsorbent with photocatalytic activity, comprising the following steps:

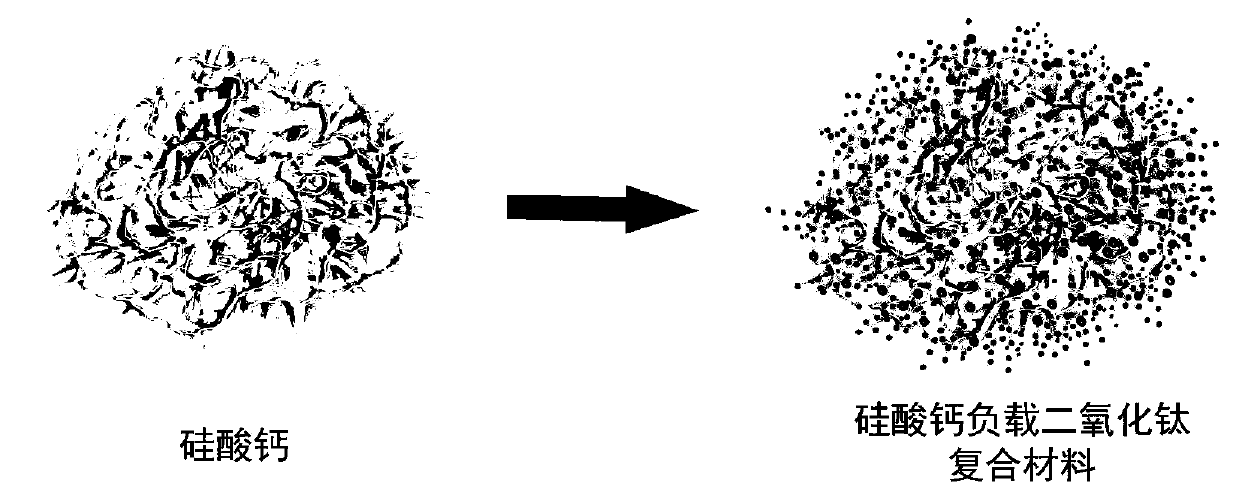

[0026] Mix water glass and calcium hydroxide for hydrothermal reaction to obtain mesoporous calcium silicate material with rich wrinkled structure on the surface;

[0027] Tetrabutyl titanate was dissolved in ethanol to obtain solution A;

[0028] Mix acetic acid, water and ethanol to obtain solution B;

[0029] Mixing the mesoporous calcium silicate material with solution B to obtain system C;

[0030] The solution A is added dropwise into the system C, and the adsorbent with photocatalytic activity is obtained through aging, drying and roasting in sequence.

[0031] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known in the art.

[0032]In the invention, water glass and calcium hydroxide are mixed for hydrothermal reaction to obtain mesoporous calcium silicate material with...

Embodiment 1

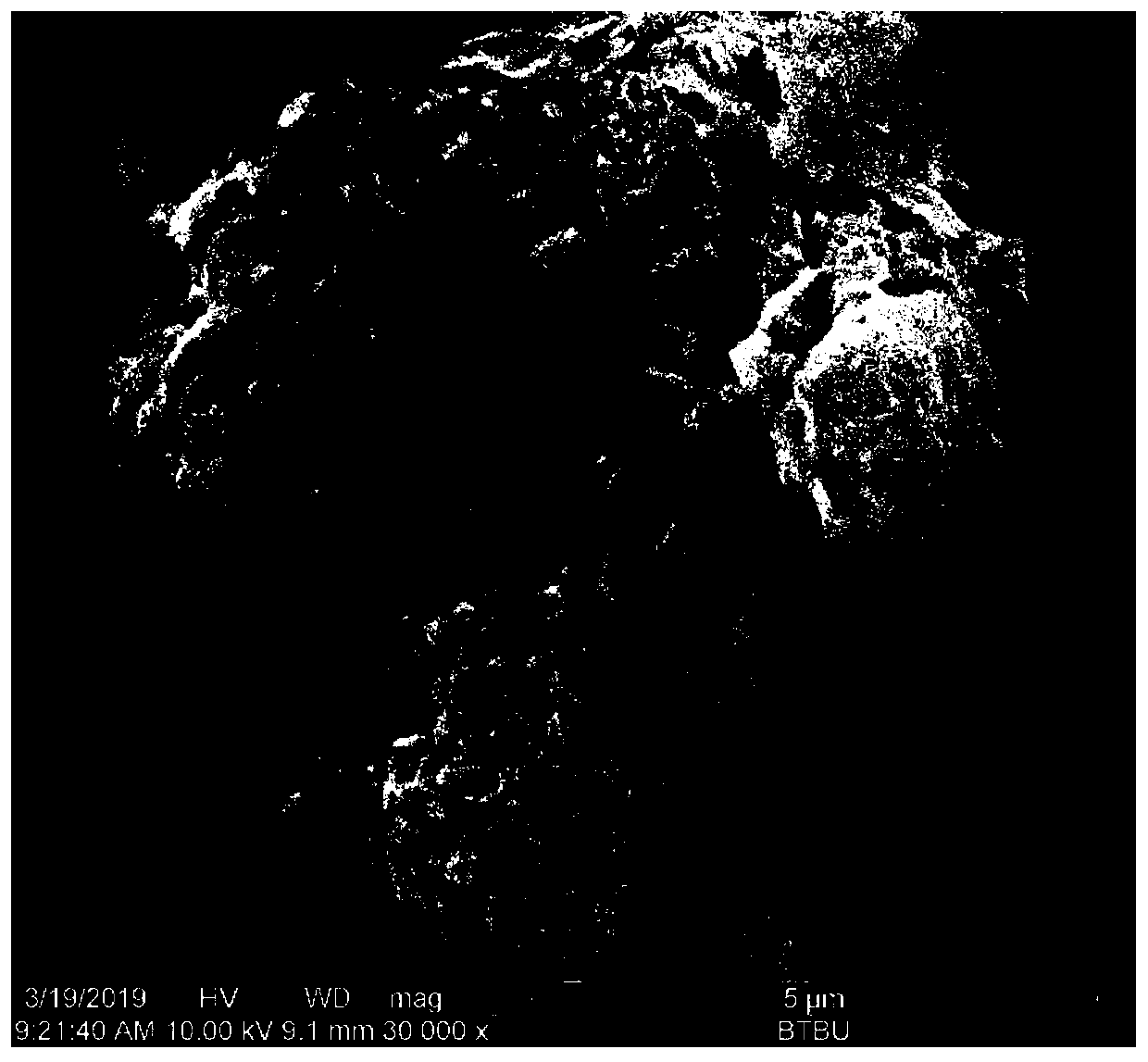

[0043] Using water glass and calcium hydroxide as materials, a mesoporous calcium silicate material (CSH) with rich wrinkle structure on the surface was synthesized by one-step hydrothermal synthesis. The specific preparation process is as follows: an appropriate amount of Na 2 SiO 3 Dissolve in deionized water, then add Ca(OH) at room temperature according to the molar ratio of Ca and Si at 1:1 under vigorous stirring 2 , and continued stirring at 70°C for 4h. Use NaOH solution to adjust the pH of the resulting system to 12, then transfer the liquid to a hydrothermal reactor, react at 120°C and 1.5MPa for 2 hours, then cool naturally to ambient temperature (about 25°C), and filter and dry Finally, CSH white powder is finally obtained.

[0044] Dissolve 10mL of tetrabutyl titanate in 35mL of absolute ethanol to obtain solution A; take 4mL of glacial acetic acid and 10mL of deionized water and dissolve them in 70mL of absolute ethanol to obtain solution B, adjust the pH to 3...

Embodiment 2

[0053] The preparation method of the mesoporous calcium silicate material is the same as in Example 1. Take 8 mL of tetrabutyl titanate in 28 mL of absolute ethanol to obtain solution A; take 3.5 mL of glacial acetic acid and 8 mL of deionized water in 60 mL of absolute ethanol to obtain solution B , adjust the pH to 3, add 3.8g of mesoporous calcium silicate material to solution B, stir rapidly to obtain system C; add solution A dropwise to system C to obtain a white sol, and obtain a white gel after aging for 18 hours. The gel was dried in an oven at 120°C and ground to powder, then placed in a muffle furnace and sintered at 500°C for 5 hours to obtain an adsorbent with photocatalytic activity and abundant wrinkles on the surface, with a loading capacity of 32.32%.

[0054] Put 2g of the above product under the irradiation power of 0.28W / m 2 The photocatalytic research of 20mg / L bisphenol A was carried out under the xenon lamp. After 7 hours of irradiation, the removal rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Hole radius | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com