Method for preparing iron-titanium-vanadium ternary inorganic polymeric flocculant based on sulfuric acid acidolysis vanadium titano-magnetite two-step method

A technology of vanadium-titanium magnetite and inorganic polymers, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water treatment parameter control, etc., can solve problems such as high temperature and insufficient stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] As a preferred embodiment of the present invention, the preparation steps of the iron-titanium-vanadium ternary inorganic polymer flocculant are as follows:

[0036] (1) Dry the vanadium-titanium-magnetite concentrate, grind it into powder, and dry it in an oven at 60°C until it reaches a constant weight.

[0037] (2) The first step reactor is placed in a constant temperature oil bath, and the temperature is controlled under magnetic stirring to carry out the acidolysis reaction. The initial concentration of sulfuric acid is set to 80%, the liquid-solid ratio is 10:1, and the acidolysis temperature is 80 ° C. Stir Rotate at 100 rpm, react until the liquid is completely volatilized, and the remaining solid is off-white.

[0038] (3) In the second step, water is added to the reactor for leaching, the liquid-solid ratio is 2:1, the leaching temperature is 80°C, and the leaching is continued for 1.5h under magnetic stirring at a speed of 100rpm.

[0039] (4) After the leac...

Embodiment 3

[0051] Applications:

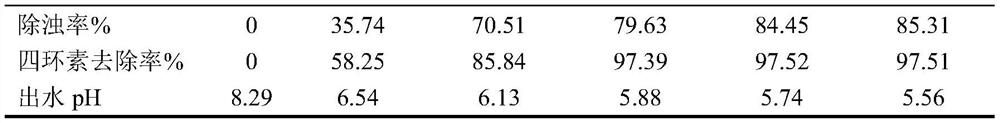

[0052] In the first step, weigh 1g of tetracycline and dissolve it in deionized water, dissolve it with ultrasonic stirring, and dilute to 1L to obtain a 1g / L tetracycline standard stock solution; dilute the 1g / L tetracycline standard stock solution to 50mg / L as a tetracycline simulation Sewage samples: by accurately pipetting a series of 1g / L tetracycline standard stock solutions and diluting them into tetracycline sewage samples with different concentration gradients.

[0053] Add 200mL of tetracycline simulated sewage samples to six beakers respectively, stir rapidly at 200r / min for 30s, add the coagulant prepared in Example 1, continue to stir rapidly for 1min, change the stirring speed to 40r / min, and after 15min, let stand After 30 minutes, water samples were taken at 2cm below the liquid surface to measure relevant water quality indicators.

[0054] The effect of iron-titanium-vanadium ternary inorganic polymer flocculant to treat tetracycline si...

Embodiment 4

[0059] Applications:

[0060] Weigh 1.0 g of waste lubricating oil into a beaker and add corresponding water, add 100 μL of surfactant, stir with magnetic force for 2 hours, and set the volume to 1 L to obtain 1000 mg / L simulated oily wastewater.

[0061] Add 200mL of simulated oily waste water to six beakers respectively, stir rapidly at 200r / min for 30s, add the coagulant prepared in Example 1, continue to stir rapidly for 1min, change the stirring speed to 40r / min, and let it stand for 30min after continuing for 15min. Water samples were taken 2cm below the liquid surface to determine relevant water quality indicators.

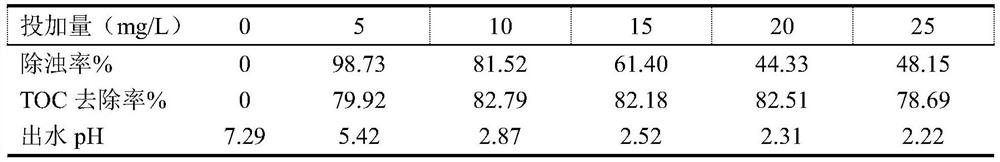

[0062] The effect of iron-titanium-vanadium ternary inorganic polymer flocculant to treat simulated oily wastewater is as follows:

[0063] Table 3. Simulated oily wastewater treatment effect

[0064]

[0065] As shown by the above application examples, the iron-titanium-vanadium ternary inorganic polymer flocculant prepared by the present invention ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com