Blue glass ceramics and preparation method thereof

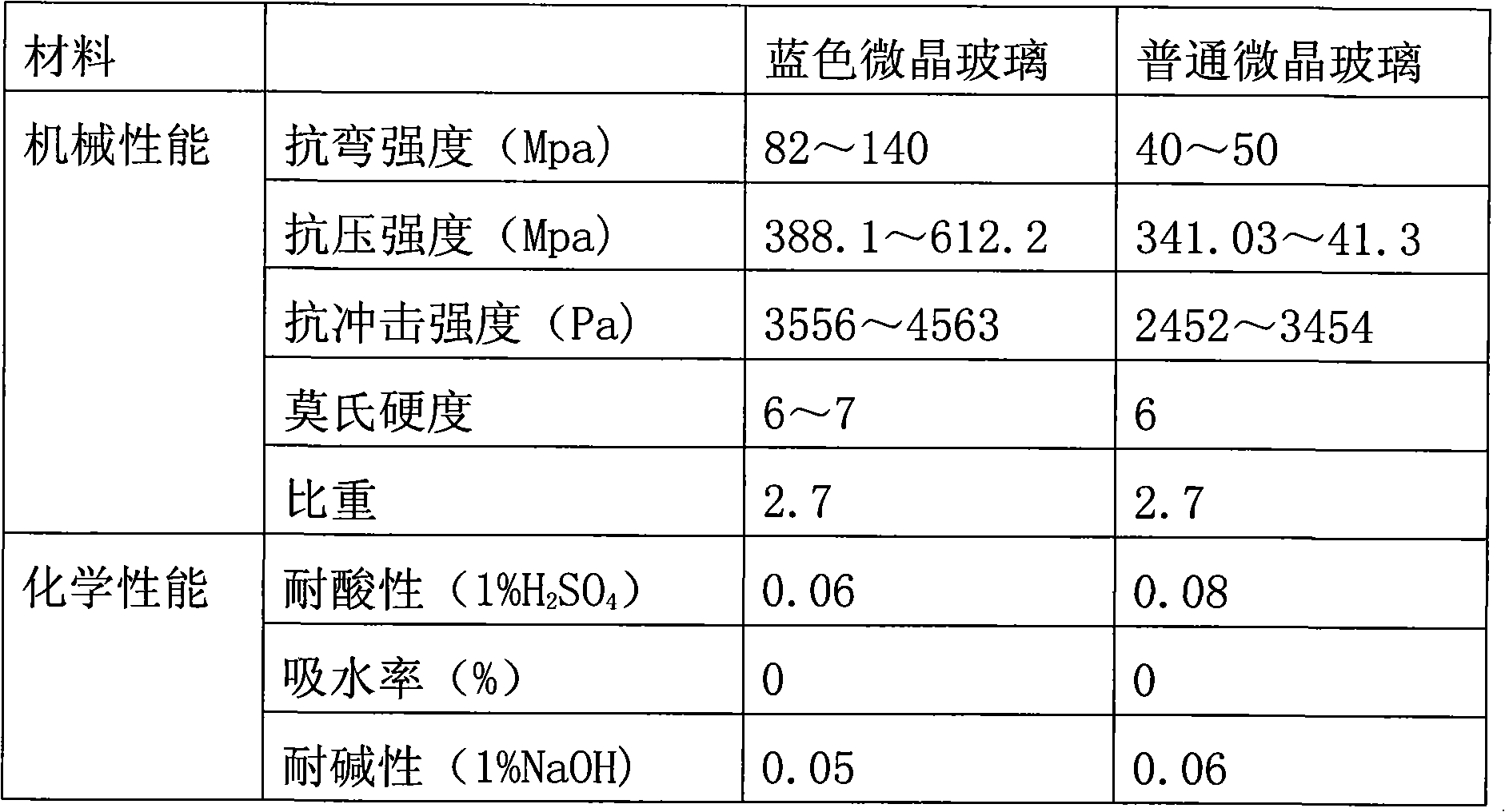

A glass-ceramic and blue technology, applied in the preparation of the blue glass-ceramic, in the field of blue glass-ceramic, can solve the problems of single color of glass-ceramic and high cost of production process, and achieve the improvement of melting furnace efficiency and increase Physical and chemical properties, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

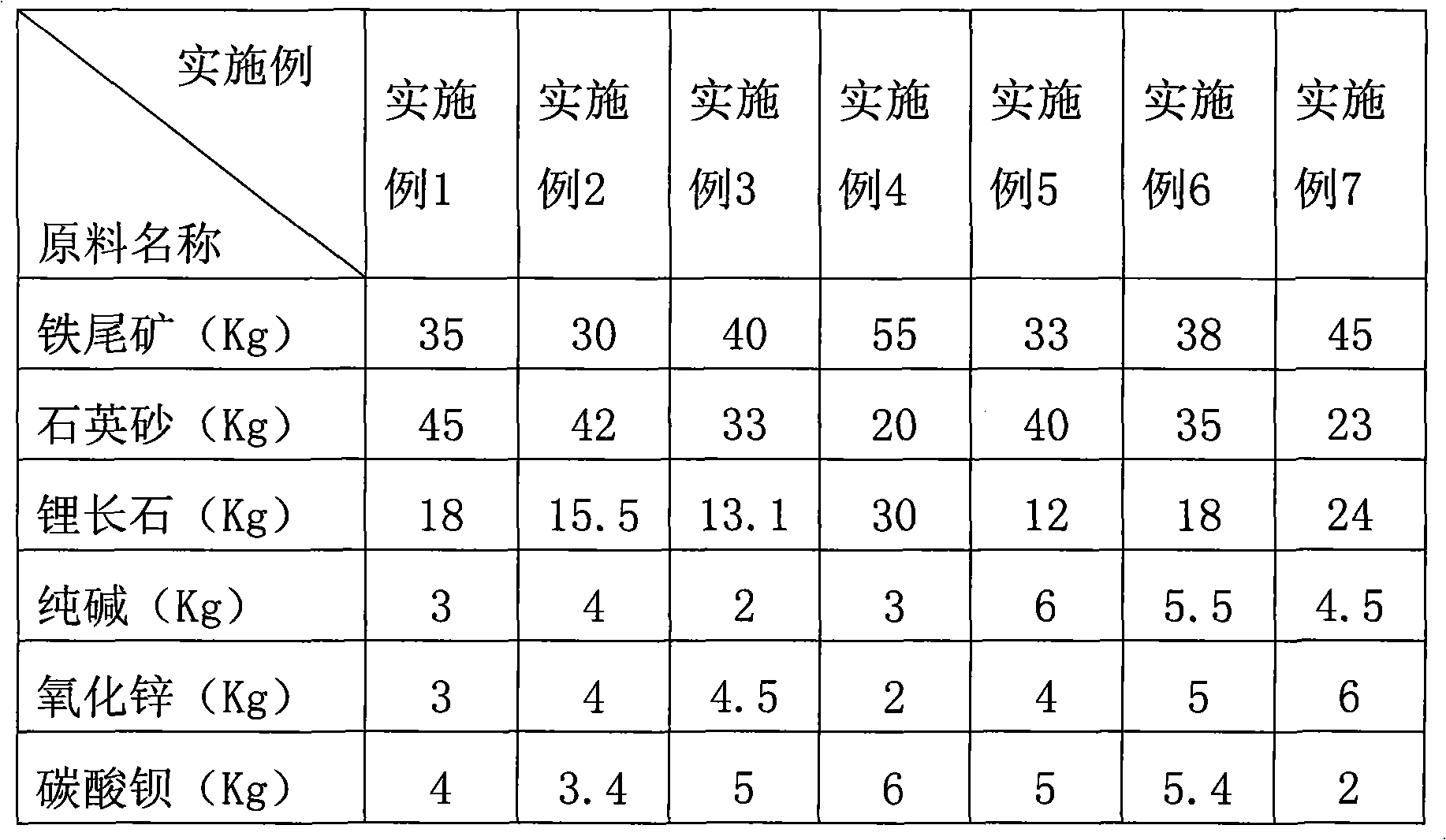

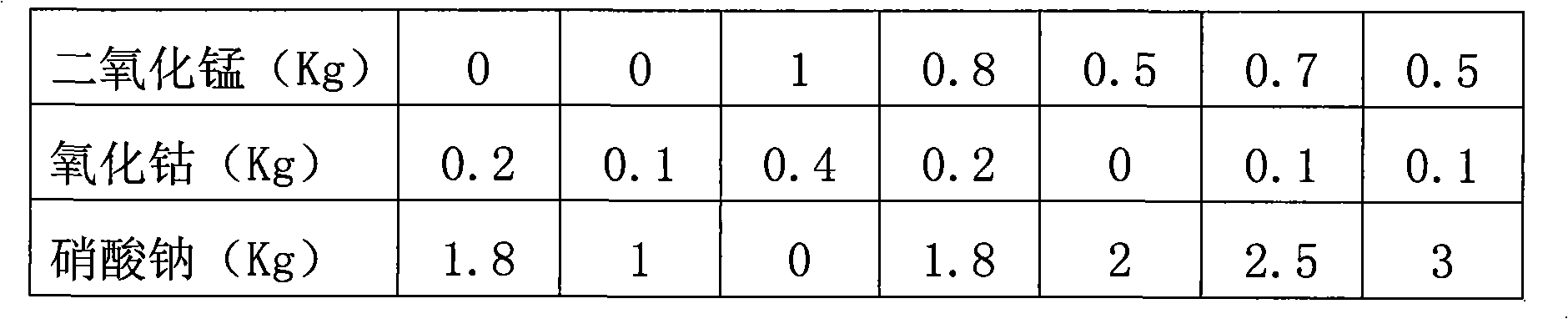

Examples

Embodiment 1

[0041] According to Table 2, each component described in Example 1 was weighed, wherein the quartz sand was vein quartz.

[0042] The preparation method comprises the following steps:

[0043] (1) Drying, sieving, and mixing the iron tailings in sequence to obtain dry powder iron tailings with a water content of 0.5% and a particle size of 40 mesh;

[0044] (2) dry powdered iron tailings are mixed with other components according to the stated ratio;

[0045] (3) Put the mixture obtained above in a box-type high-temperature electric furnace, and melt it at a temperature of 1500° C. for 1 hour to obtain molten glass with a viscosity of 10 Pa.s;

[0046] (4) The molten glass is flowed into water, and the water is quenched to become glass pellets;

[0047] (5) Put the glass pellets into the mold for nucleation and crystallization molding, nucleate at 650°C for 0.8 hours, then raise the temperature to 1060°C at a rate of 4.7°C / min, and crystallize and shape at a pressure of 25Pa ...

Embodiment 2

[0049] According to Table 2, the components described in Example 2 were weighed, wherein the quartz sand included a mixture of 40% vein quartz and 60% quartzite.

[0050] The preparation method comprises the following steps:

[0051] (1) drying, sieving, and mixing the iron tailings successively to obtain dry powder iron tailings with a water content of 1% and a particle size of 80 mesh;

[0052] (2) dry powdered iron tailings are mixed with other components according to the stated ratio;

[0053] (3) Put the mixture obtained above in a box-type high-temperature electric furnace, and melt it at a temperature of 1510° C. for 2 hours to obtain molten glass with a viscosity of 10.5 Pa.s;

[0054](4) The molten glass is flowed into water, and the water is quenched to become glass pellets;

[0055] (5) Put the glass pellets into the mold for nucleation and crystallization molding, nucleate at 650°C for 1 hour, then raise the temperature to 1040°C at a rate of 4.7°C / min, and cryst...

Embodiment 3

[0057] According to Table 2, each component described in Example 3 was weighed, wherein the quartz sand was opal.

[0058] The preparation method comprises the following steps:

[0059] (1) drying, sieving, and mixing the iron tailings successively to obtain dry powder iron tailings with a water content of 3% and a particle size of 120 mesh;

[0060] (2) dry powdered iron tailings are mixed with other components according to the stated ratio;

[0061] (3) Put the mixture obtained above in a box-type high-temperature electric furnace, and melt it at a temperature of 1520° C. for 2.5 hours to obtain molten glass with a viscosity of 11 Pa.s;

[0062] (4) The molten glass is flowed into water, and the water is quenched to become glass pellets;

[0063] (5) Put the glass pellets into the mold for nucleation and crystallization molding, nucleate at 650°C for 0.9 hours, then raise the temperature to 1020°C at a rate of 4.7°C / min, and crystallize and shape at a pressure of 25Pa , t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com