Manufacturing method for car tire with side wall colored patterns

A color pattern and manufacturing method technology, applied in the field of vehicle tire manufacturing, can solve problems such as difficulties in the production process, and achieve low cost, outstanding effect, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described in detail below in conjunction with specific examples.

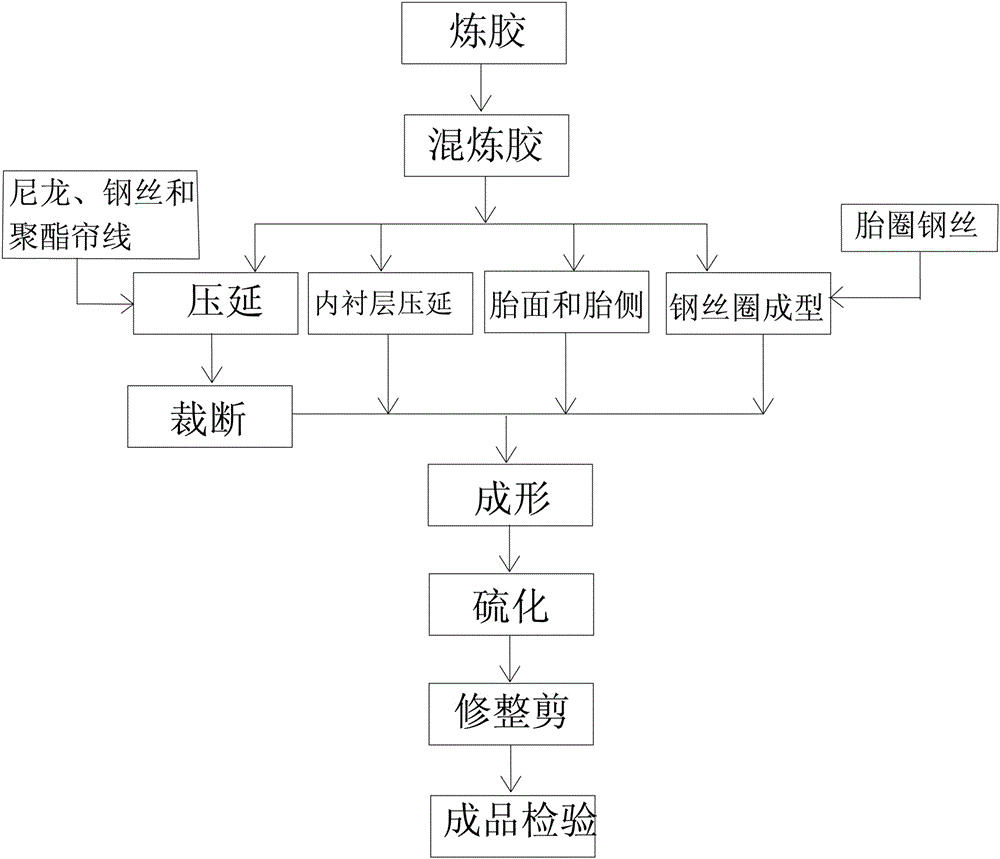

[0035] Tires are divided into automobile tires, engineering machinery tires, agricultural machinery tires, motorcycle tires, rickshaw tires, etc. according to the use category. The production process is also different, and the application requirements of the present invention are also different. The outer side can be printed on one side, while the tires need to be printed on both sidewalls of the tires. Now take the production of the tires as an example to illustrate the production process. The process flow chart is attached. figure 1 .

[0036] The manufacturing method of the rickshaw tire with sidewall color patterns is as follows:

[0037] 1 Rubber mixing process

[0038] The rubber mixing process is to mix carbon black, natural / synthetic rubber, oil, additives, accelerators and other raw materials together (select raw materials and components according to the needs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com