Infrared high-emissivity coating material and preparation method thereof

A high emissivity, coating material technology, applied in coatings, alkali metal silicate coatings, etc., can solve the problems of coating emissivity attenuation, affecting service life, high cost, stable infrared emissivity, infrared emission High efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

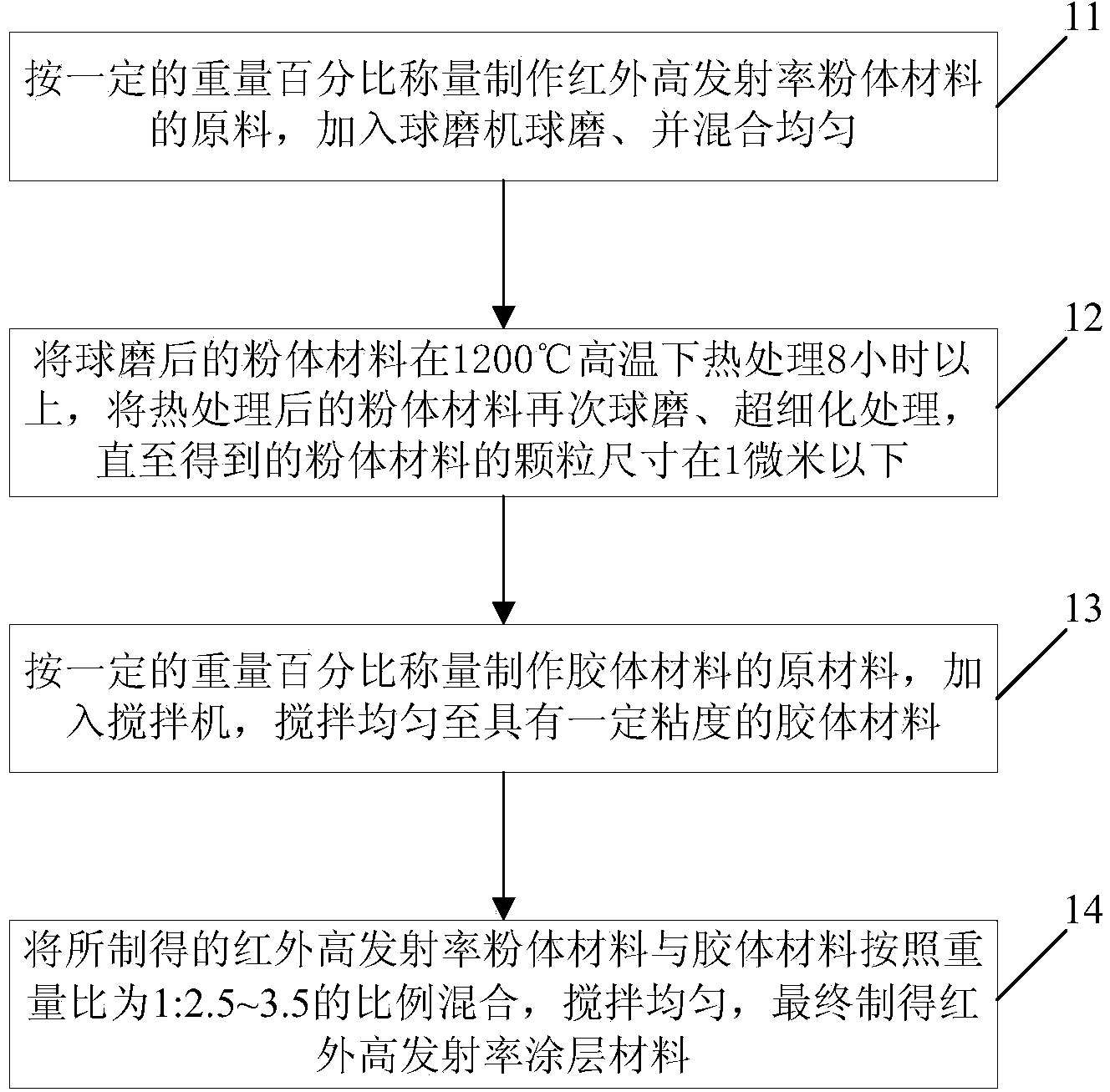

[0040] Based on the above-mentioned infrared high emissivity coating material, the embodiment of the present invention also provides a preparation method of an infrared high emissivity coating material, such as figure 1 Shown is a schematic flow chart of the preparation method of the infrared high-emissivity coating material described in the embodiment of the present invention, and the preparation method includes:

[0041] Step 11: Weigh the raw materials for making infrared high-emissivity powder materials according to a certain weight percentage, add them to a ball mill and mix them evenly

[0042] In this step, the weight percent of the raw material of the infrared high emissivity powder material is: iron slag: 45-75%; iron oxide: 0-10%; manganese oxide: 5-15%; zirconia: 5% -15%; Chromium Oxide: 5-15%; Silicon Carbide: 5-15%.

[0043] Step 12: heat-treat the ball-milled powder material at a high temperature of 1200°C for more than 8 hours, ball-mill the heat-treated powder...

Embodiment 1

[0049] 1. Weigh 2kg of iron slag, 0.4kg of iron oxide, 0.4kg of manganese oxide, 0.4kg of zirconia, 0.4kg of chromium oxide, and 0.4kg of silicon carbide, add them to a ball mill, grind for several hours, and mix the powder evenly.

[0050] 2. The powder mixed by the ball mill is heat-treated at a high temperature of 1200° C. for 12 hours to obtain a powder material with high infrared emissivity.

[0051] 3. After the heat treatment is finished, cool down to room temperature, and ball mill the powder for several hours to obtain an ultrafine powder with a particle size below 1 micron.

[0052] 4. Take again 10kg of water, 2.5kg of water glass, 0.125kg of carboxymethyl cellulose, and 0.5kg of ultrafine silicon dioxide, put them into a blender, and stir until viscous colloidal material.

[0053] 5. Weigh the infrared high-emissivity powder material and colloidal material in a weight ratio of 1:3, stir and mix evenly, and then obtain the usable infrared high-emissivity coating mat...

Embodiment 2

[0055] 1. Weigh 1.8kg of silicon dioxide, 0.6kg of iron oxide, 0.4kg of manganese oxide, 0.4kg of zirconia, 0.4kg of chromium oxide, and 0.4kg of silicon carbide, add to a ball mill, grind and mix well.

[0056] 2. Heat-treat the mixed powder at a high temperature of 1200°C for 12 hours to obtain a powder material with high infrared emissivity.

[0057] 3. After the heat treatment is completed, the powder is ball milled to obtain an ultra-fine powder below 1 micron.

[0058] 4. Weigh 10 kg of water, 2 kg of aluminum dihydrogen phosphate, 0.125 kg of carboxymethyl cellulose, and 0.5 kg of ultrafine silicon dioxide, put them into a blender, and stir until viscous colloidal material.

[0059] 5. Weigh the infrared high-emissivity powder material and colloidal material in a weight ratio of 1:3, stir and mix evenly, and then obtain the usable infrared high-emissivity coating material.

[0060] The infrared high-emissivity coating material prepared according to the above process ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com