Method for recovering valuable metal from waste residue containing lead and zinc through wet-fire combination process

A combined process and valuable metal technology, applied in the field of metal smelting, can solve the problems of high impurity content, high processing cost, low recovery rate, etc., and achieve the effect of high recovery rate, avoiding pollution, high yield and product taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

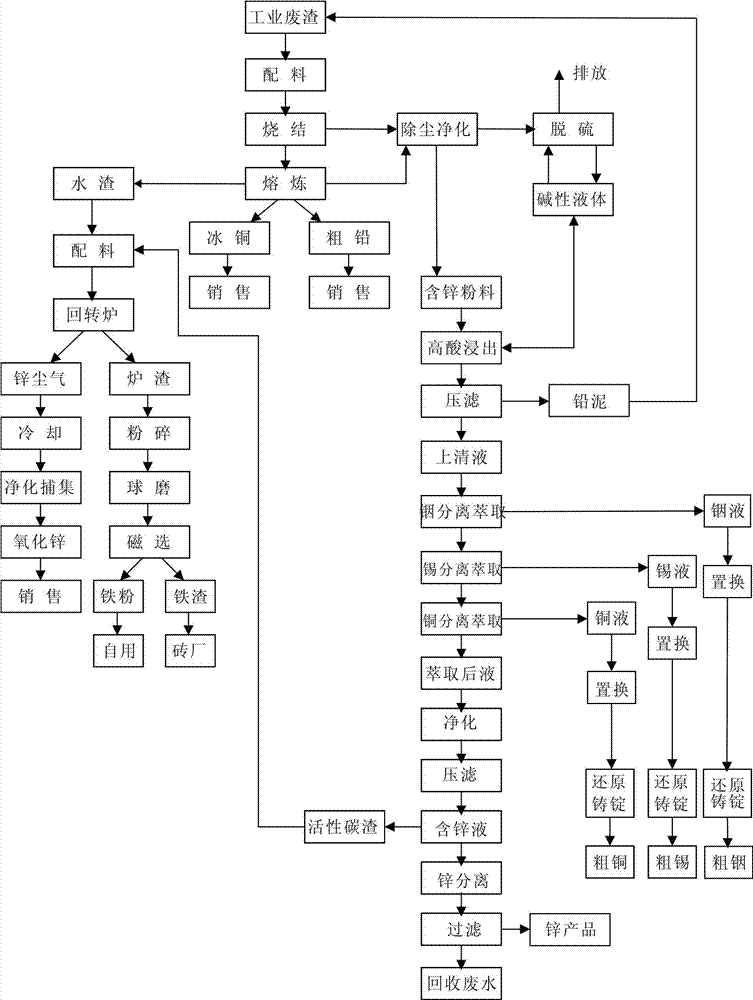

Image

Examples

Embodiment 1

[0052] a. Take zinc-lead waste residue from an electrolytic zinc enterprise in Shimian County (main content: 20-30% lead, 6-8% zinc, 25-28% water, 0.5-1.5% copper, 0.02-0.06% indium and tin 0.03-0.08%) 200kg, then mixed with 14% water, 7% coal powder, 2% silica, 5% limestone and 25% iron powder, and the bulk material was crushed by the crusher until the particle size was less than 1cm, the crushed material is ground by a pulverizer, and the particle size of 90% of the mixed material is controlled to be below -100 mesh to obtain a powder; then it is added to a disc pelletizer for pelletizing to obtain pellets; The ore is put into the sintering machine and sintered at 600-650°C for 5 hours to obtain a sintered block; the prepared sintered block is mixed with 10% coke, mixed with a mixer, and then melted in a blast furnace to obtain metal lead, ice Copper phase, soot phase and water slag; the technological conditions of the smelting process are controlled as follows: the blast fu...

Embodiment 2

[0060] a. Take zinc-lead waste residue from an electrolytic zinc enterprise in Shimian County (main content: 20-30% lead, 6-8% zinc, 25-28% water, 0.5-1.5% copper, 0.02-0.06% indium and tin 0.03-0.08%) 300kg, then mixed with 16% water, 8% coal powder, 3% silica, 7% limestone and 27% iron powder, the bulk material is crushed by the crusher until the particle size is less than 2cm, the crushed material is ground by a pulverizer, and the particle size of 90% of the mixed material is controlled to be below -100 mesh to obtain a powder; then it is added to a disc pelletizer for pelletizing to obtain pellets; Put the ore into the sintering machine and sinter at 600-650°C for 6 hours to obtain a sintered block; add 15% coke to the obtained sintered block, mix it with a mixer, and then enter the blast furnace for smelting to obtain metal lead, ice Copper phase, soot phase and water slag; the technological conditions of the smelting process are controlled as follows: the blast furnace ...

Embodiment 3

[0068] a. Take zinc-lead waste residue from an electrolytic zinc enterprise in Shimian County (main content: 20-30% lead, 6-8% zinc, 25-28% water, 0.5-1.5% copper, 0.02-0.06% indium and tin 0.03-0.08%) 400kg, then mixed with 15% water, 7.5% coal powder, 2.5% silica, 6% limestone and 26% iron powder, and the bulk material was crushed by the crusher until the particle size was less than 2cm, the crushed material is ground by a pulverizer, and the particle size of 90% of the mixed material is controlled to be below -100 mesh to obtain a powder; then it is added to a disc pelletizer for pelletizing to obtain pellets; Put the ore into the sintering machine and sinter at 600-650°C for 5.5 hours to obtain a sintered block; add 13% coke to the obtained sintered block, mix it with a mixer, and then enter the blast furnace for smelting to obtain metal lead, ice Copper phase, soot phase and water slag; the technological conditions of the smelting process are controlled as follows: the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com