Floatation process of complex lead zinc ores

A lead-zinc ore and flotation technology, applied in flotation, solid separation, etc., can solve the problems of heavy acidity, high sulfur content, high carbon content, etc., and achieve the effect of reducing the circulation volume of medium ore, reducing circulation volume, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

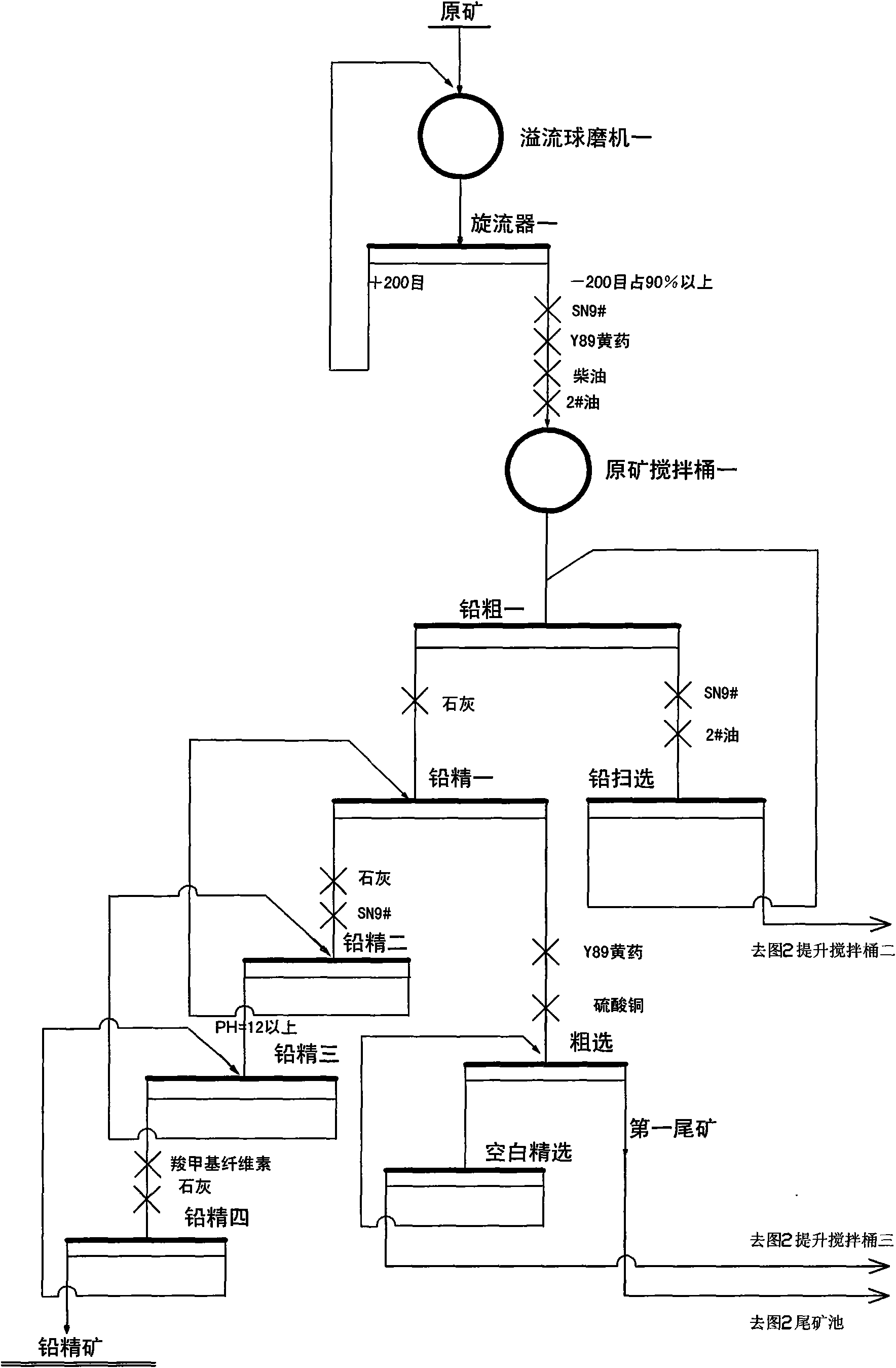

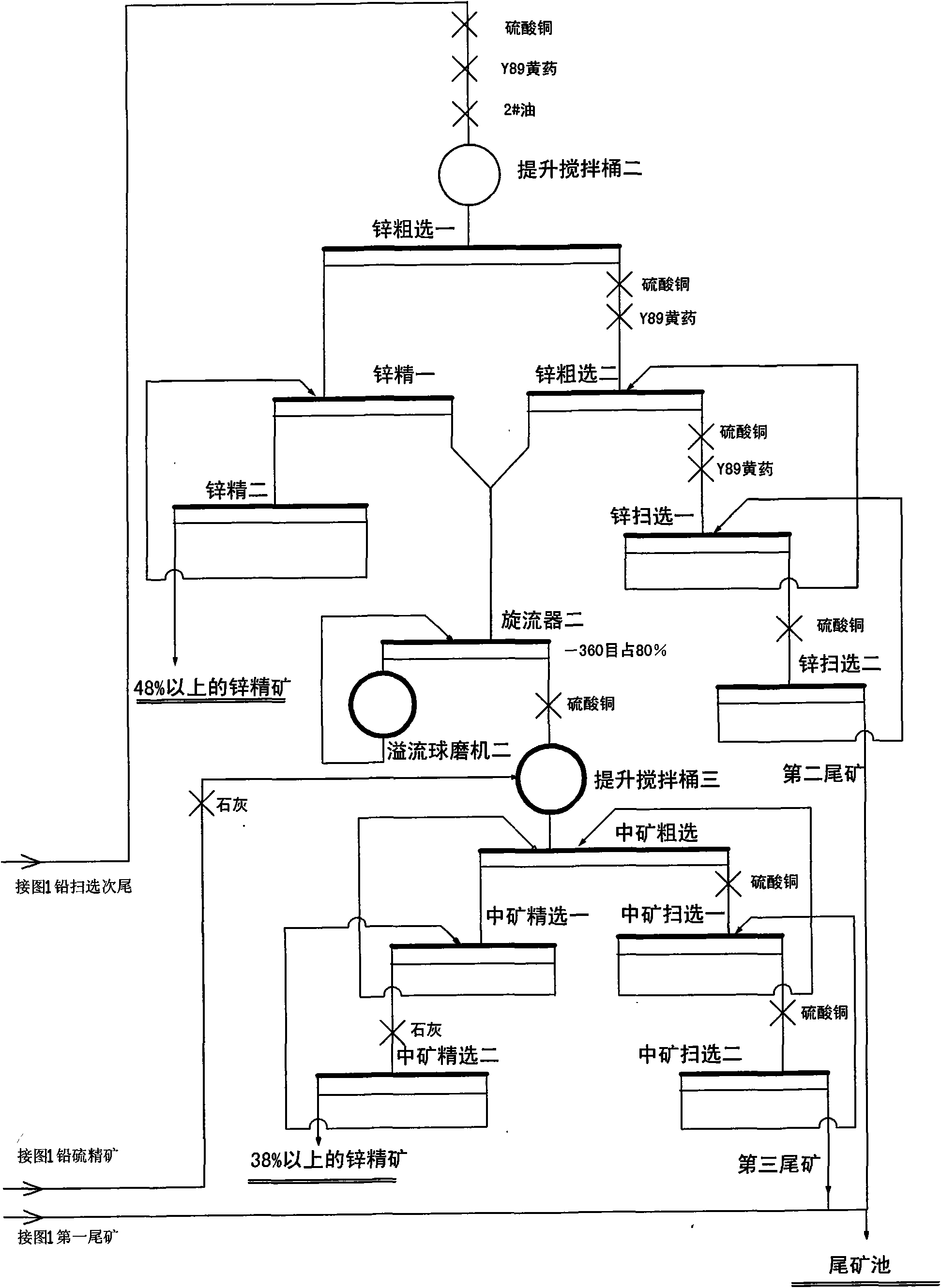

[0047] In order to describe the present invention in detail, the present invention will be further described in detail below in conjunction with the beneficiation process and accompanying drawings of the Duda lead-zinc ore in the Duda area of Pakistan.

[0048] Basic situation of Duda ore

[0049] In the ore of Duda lead-zinc ore, the main metal minerals are galena, white plumbite, sphalerite, smithsonite, marcasite, pyrite, chalcopyrite, copper blue, tetrahedrite, silver tetrahedrite ore, etc.; gangue minerals include carbonaceous shale, organic carbon, quartz, feldspar, calcite, chlorite, apatite, and barite.

[0050] That is to say, in addition to iron sulfide minerals, lead and zinc and other metal minerals, the surrounding rocks are mainly carbonaceous shale and organic carbon.

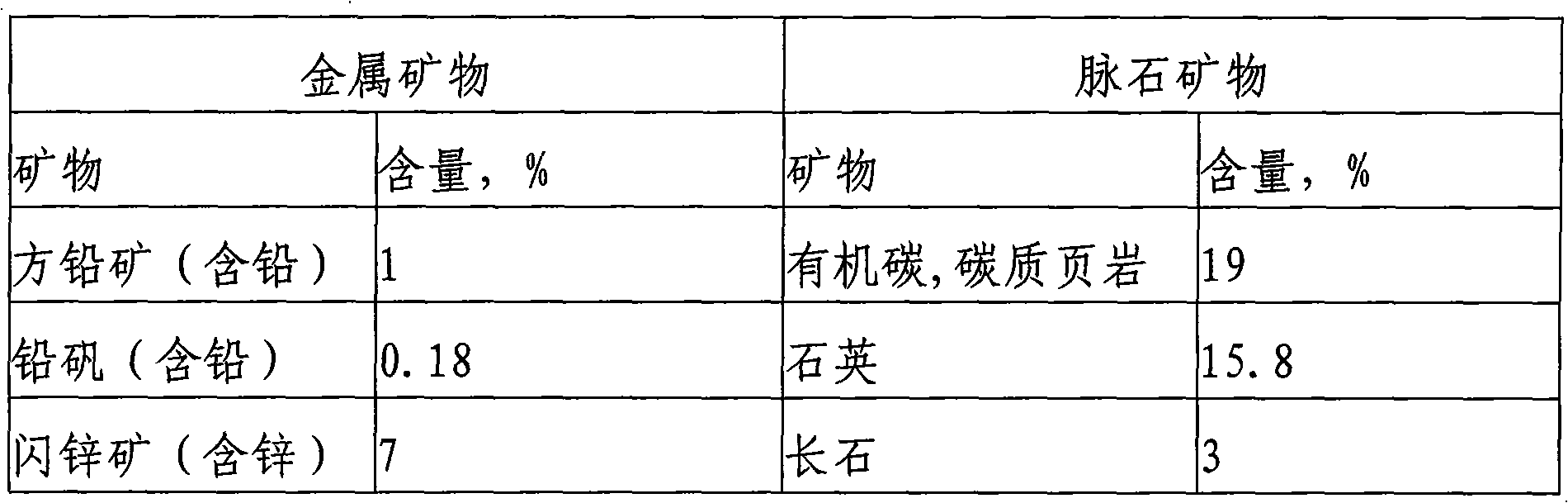

[0051] (1) Mineral composition and content

[0052]

[0053]

[0054] (2) The structure of the ore

[0055] The structure of the ore mainly includes euhedral, semi-euhedral crystal str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com