Comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc

A recovery method and multi-metal technology, applied in the direction of sulfur preparation/purification, flotation, solid separation, etc., can solve the problems of increasing the difficulty of processing and production costs, unfavorable sulfur recovery and environmental protection, and unsuitable for long-distance transportation. The effect of compact and smooth process structure, reduced beneficiation cost and simplified pharmaceutical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

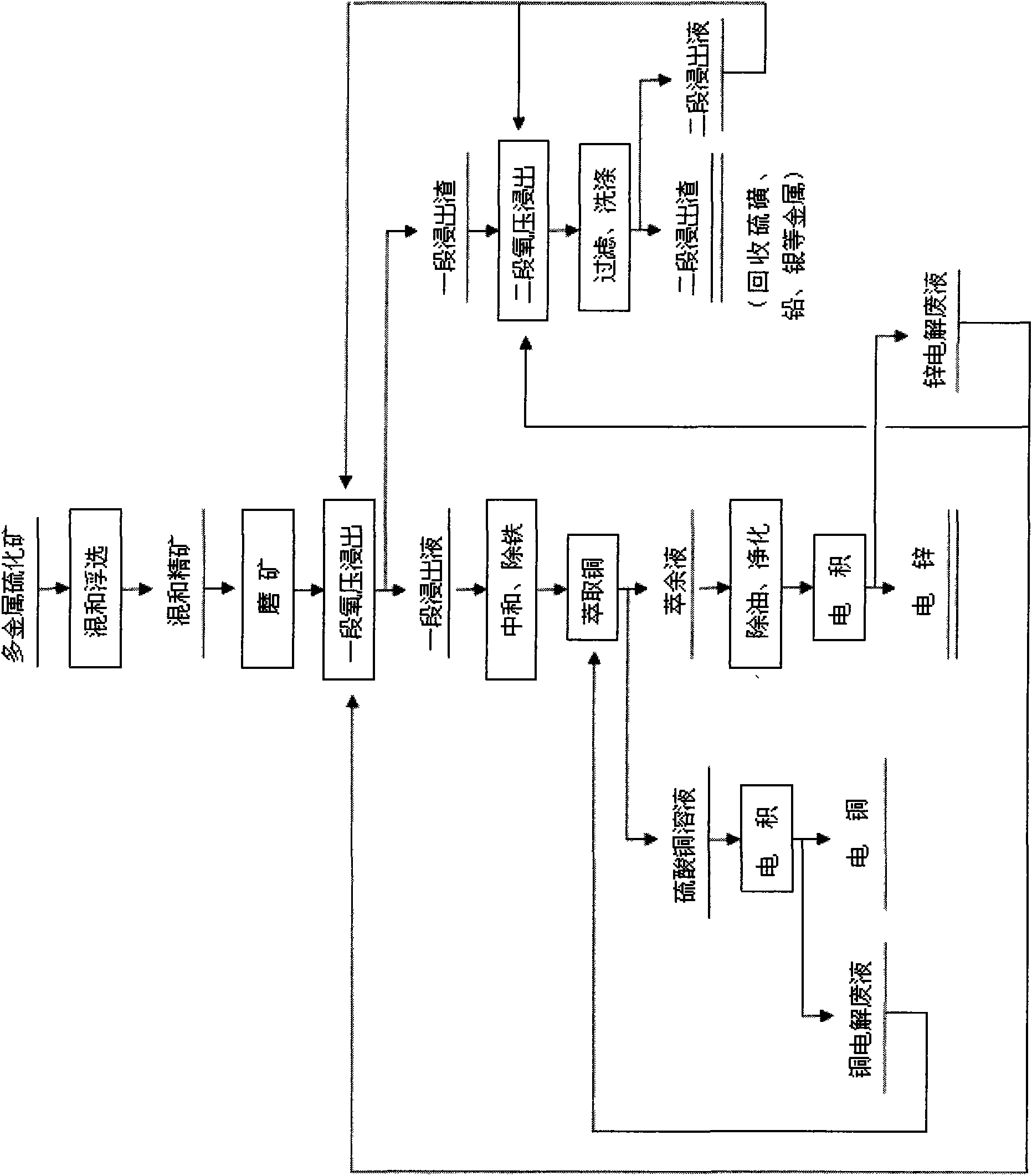

Method used

Image

Examples

Embodiment 1

[0024] The percentages described in the examples are all mass percentages.

[0025] The typical chemical composition of this sulfide ore is shown in Table 1:

[0026] Table 1 Chemical composition of raw ore

[0027] Element

Cu

Pb

Zn

Ag*

Au*

Content%

0.54

4.11

6.44

136

0.26

Element

As

Sb

CD

Fe

S

Content%

0.068

0.4

0.034

5.50

10.08

[0028] *The unit is g / t.

[0029] According to X-ray diffraction analysis, the main metal minerals in this mineral are sphalerite, galena, tetrahedrite (mainly Sb-rich tetrahedrite), pyrite, chalcopyrite, and tetrahedrite. The relative content of ore is obviously more than that of chalcopyrite, and most of Cu, Ag and As are contained in it.

[0030] Step 1: Perform mixed flotation on the mined complex copper-lead-zinc-silver polymetallic sulfide ore to obtain polymetallic mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com