Beneficiation method for cu-pb-zn polymetallic ores

A technology for polymetallic ores and beneficiation methods, applied in the direction of solid separation, etc., can solve the problems of high mutual content of concentrates, difficult separation, unqualified product quality, etc., to improve concentrate grade and recovery rate, improve production environment, The effect of drug dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

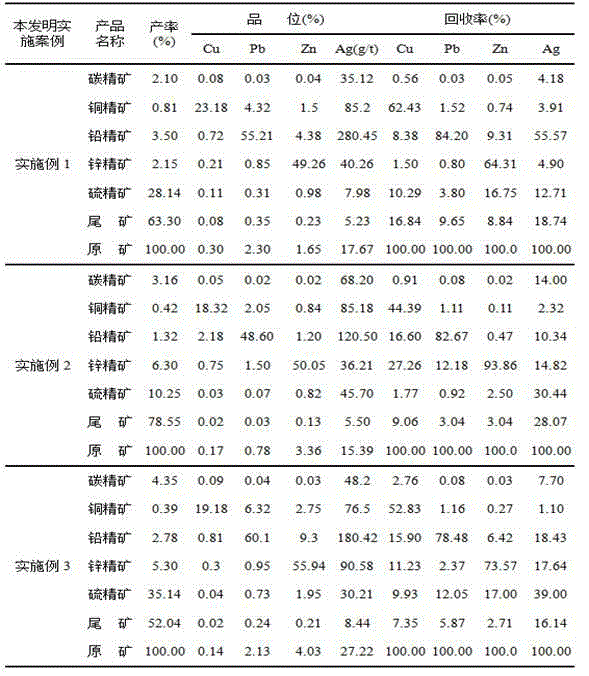

[0035] Example 1: A polymetallic ore deposit in Qinghai is selected as the disseminated copper-lead-zinc polymetallic ore as the raw ore. In this ore, chalcopyrite, galena, sphalerite, and pyrrhotite are embedded with uneven particle size and symbiotic The relationship is complex, the copper grade is low, the zinc mineral is mainly sphalerite, and the magnetite content is as high as 28%, which is a typical complex polymetallic sulfide ore. The ore contains Cu0.30%, Pb2.30%, Zn1.65%, S12.73%, Ag17.67g / t, and carbon 3.80%.

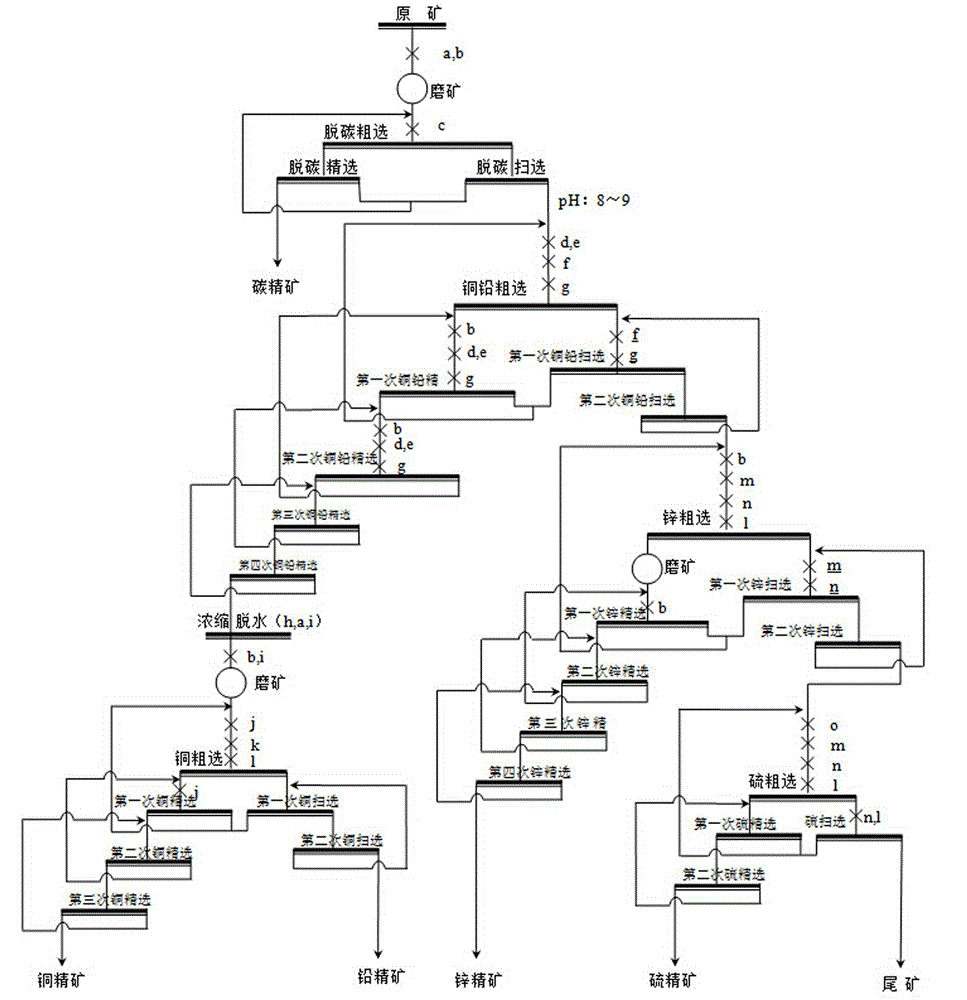

[0036] likefigure 1 A kind of beneficiation method of copper-lead-zinc polymetallic ore shown, comprises the following steps:

[0037] Raw ore grinding: The crushed raw ore and water are added to the ball mill in a ratio of 1:1 for grinding, and the amount of sodium sulfide (a) is 200g / t and lime (b) is 2500g / t ( Based on the weight of raw ore dry ore, the same below), until the grinding fineness of the ore grinding product is -74μm, it accounts for 70%; pr...

Embodiment 2

[0042] Example 2: The raw ore is selected from a complex copper-lead-zinc sulfide ore in Tibet, which is a typical refractory polymetallic sulfide ore with a complex intercalation relationship. The copper minerals in this ore are mainly chalcopyrite, and the chalcopyrite distribution is uneven. It belongs to fine-grained inlaid cloth, generally between 0.01-0.2mm, coarse-grained up to 2mm, and fine-grained less than 0.005mm; Iron ore and arsenopyrite are closely symbiotic, and the results of particle size screening show that the copper and lead in the ore are interspersed with finer particles and complex characteristics; The iron ore mosaic relationship is relatively close, and encased mosaic and interlaced mosaic are more common; pyrrhotite chalcopyrite less than 0.037mm has a large proportion, and it exists in sphalerite in the form of emulsion droplet and irregular fine grain inclusions Medium; ore contains C 4.10%, Cu 0.17%, Pb

[0043] Such as figure 1 A kind of benefic...

Embodiment 3

[0049] Example 3: The raw ore is selected from a copper-lead-zinc polymetallic sulfide ore in Gansu. The useful minerals in the ore are not only fine in particle size, but also complex in distribution, and the ore is a complex high-sulfur polymetallic sulfide ore. Valuable metals are sphalerite, galena and pyrite, followed by a small amount of chalcopyrite, which is unevenly distributed and is fine-grained; sphalerite and pyrrhotite, pyrite, The intercalation relationship of chalcopyrite is very close, and wrapped inlay and interlaced inlay are more common; the results of particle size analysis show that the intercalation relationship of chalcopyrite and galena is complex and the particle size is fine; the ore contains Cu0.14%, Pb2.13%, Zn4.03%, S17.16%, Ag27.22g / t.

[0050] Such as figure 1A kind of beneficiation method of copper-lead-zinc polymetallic ore shown, comprises the following steps:

[0051] Raw ore grinding: the crushed raw ore and water are put into a ball mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com