Solidification treatment process of smelting waste of lead and zinc

A technology for solidification treatment and waste residue, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., and can solve problems such as large porosity, anti-solubility, and environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A solidification treatment process for lead-zinc smelting waste slag, comprising the following steps:

[0021] (1) Pretreatment of lead-zinc smelting waste residue

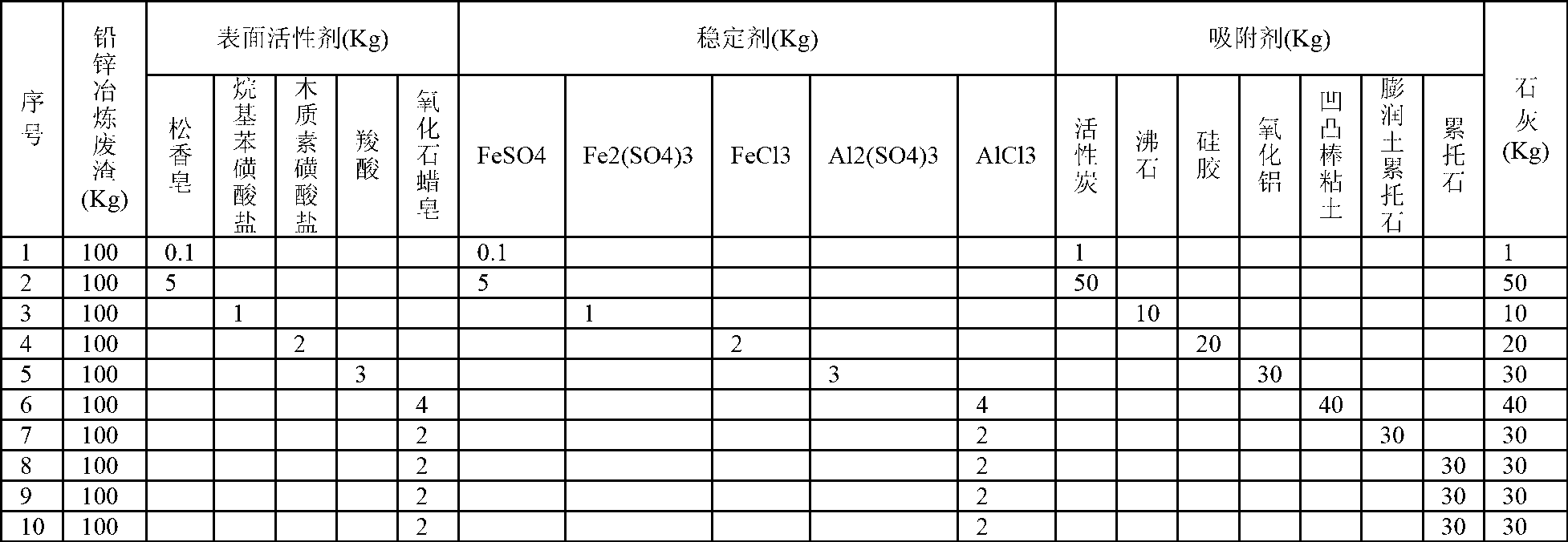

[0022] Add surfactant, stabilizer, adsorbent and lime to lead-zinc smelting waste residue, and stir evenly, wherein, the components and addition amount of surfactant, stabilizer, adsorbent and lime refer to Table 1; Table 1 column The formula composition of 10 embodiments numbered 1-10 has been shown.

[0023] (2) Treatment of hydraulic cementitious materials

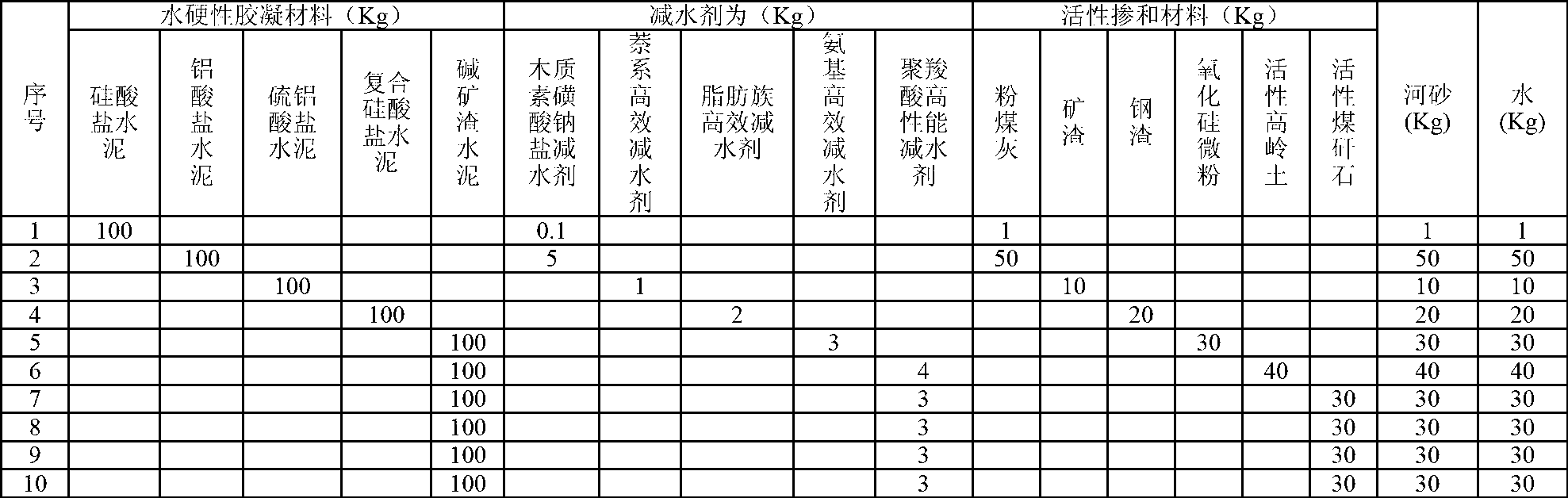

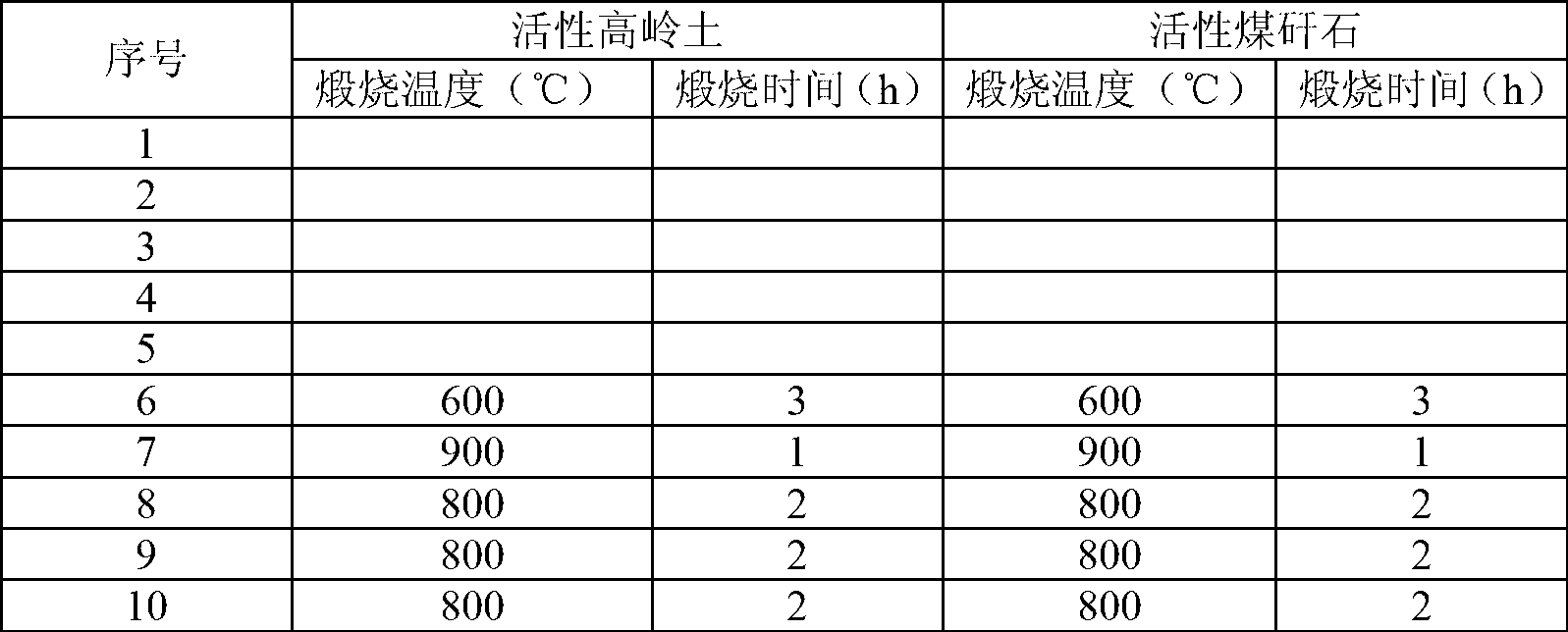

[0024] Add water reducing agent, active blending material, river sand and water to the hydraulic cementitious material, and mix evenly, wherein, the components of cementitious material, water reducing agent, active blending material, river sand, and water And add-on reference table 2; Table 2 has listed the formula composition of 10 embodiments numbered 1-10. The active kaolin in the active blending material is made by calcining kaolin ore at 600-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com