Grease for motor bearings of wind generators and production method thereof

A bearing grease, motor and motor technology, applied in the field of grease, can solve the problems of reduced overall fan efficiency, poor anti-friction and extreme pressure performance, short service life, etc., and achieve good waterproof and anti-corrosion performance, good friction reduction and reduction Noise performance, effect of wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

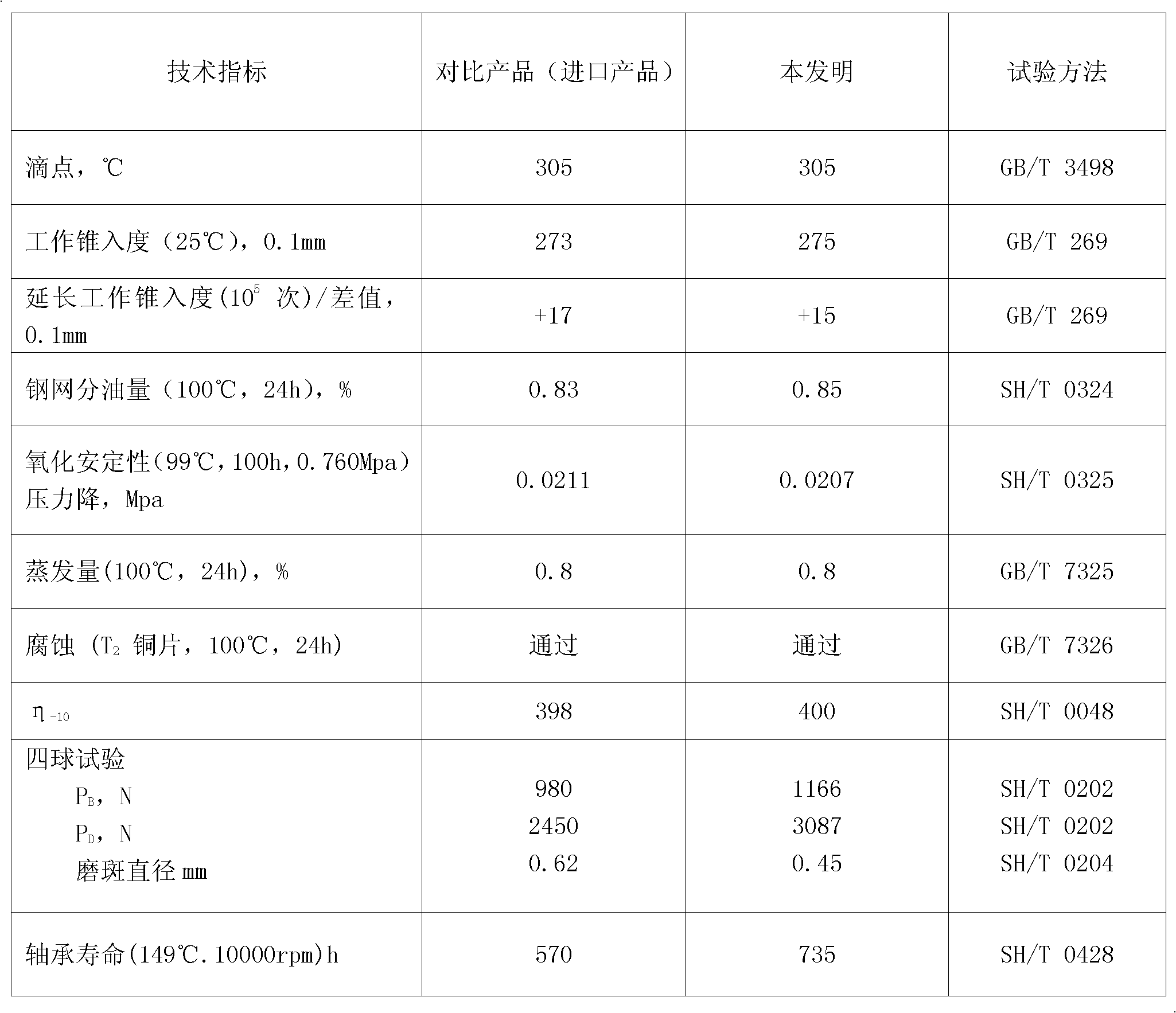

Examples

Embodiment 1

[0036] Wind turbine motor bearing grease, including the following components blended according to weight ratio:

[0037] 9kg of 12-hydroxystearic acid, 3kg of sebacic acid, 2.6kg of lithium hydroxide, 80.6kg of base oil, 3kg of extreme pressure agent, 1kg of antioxidant, 0.5kg of rust inhibitor, and 0.3kg of metal passivator;

[0038] The production method of wind turbine motor bearing grease, its specific operation steps are as follows:

[0039] 1) Add all the base oil in the formula to the saponification kettle, stir at a speed of 30-60 rpm, then add all the 12 hydroxystearic acid in the formula, heat up to 90-100°C to dissolve all the 12 hydroxystearic acid ;

[0040] 2) Dissolve 1 / 2 part of the formula amount of lithium hydroxide in 6-10 times hot water at 95-100°C, and slowly add it to the mixture obtained in step 1) for saponification reaction. The addition time is not less than 30 minutes, and the saponification reaction time is not After less than 1 hour, slowly heat...

Embodiment 2

[0046] Wind turbine motor bearing grease, including the following components blended according to weight ratio:

[0047] 11.2kg of 12-hydroxystearic acid, 3.8kg of sebacic acid, 3.2kg of lithium hydroxide, 74.4kg of base oil, 4kg of extreme pressure agent, 1.5kg of antioxidant, 1.5kg of rust inhibitor, and 0.4kg of metal deactivator;

[0048] The production method of the wind-driven generator motor bearing grease is the same as in Example 1.

Embodiment 3

[0050] Wind turbine motor bearing grease, including the following components blended according to weight ratio:

[0051] 13.5kg of 12-hydroxystearic acid, 4.5kg of sebacic acid, 3.9kg of lithium hydroxide, 70.6kg of base oil, 5kg of extreme pressure agent, 1kg of antioxidant, 1kg of rust inhibitor, and 0.5kg of metal deactivator;

[0052] The production method of the wind-driven generator motor bearing grease is the same as in Example 1.

[0053] In the above examples, the base oil refers to a mixed oil composed of isotridecyl adipate, PAO10, PAO40 and alkylnaphthalene, and its mixing ratio is isotridecanyl adipate: PAO10: PAO40: alkylnaphthalene =10:20:60:10. Extreme pressure agent refers to a mixture composed of thiocarbamate, triphenyl thiophosphate, molybdenum oxysulfide carbamate and nano-calcium carbonate, and its mixing ratio is thiocarbamate: triphenyl thiophosphate : molybdenum oxysulfide carbamate: nano calcium carbonate = 10:50:10:30. The antioxidant is octylbuty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com