A kind of preparation method of polycondensation catalyst, the catalyst prepared by it and the method for preparing PBS and copolymer thereof with the catalyst

A technology of polycondensation catalyst and copolymer, which is applied in the field of polybutylene succinate and its copolymer, can solve the problems of many by-products, low reactivity, poor product color, etc., and achieve easy operation, increased polymerization rate, The effect of enhancing the luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

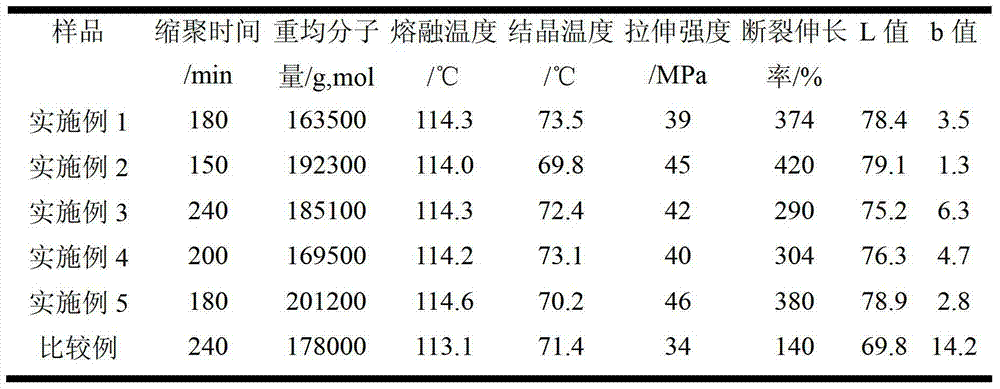

Examples

Embodiment 1

[0036] 1.1 Catalyst preparation process

[0037] Mix 5g of n-butyl titanate, 1g of polyacrylamide, 2ml of concentrated hydrochloric acid and 30ml of distilled water, set the reaction temperature at 10°C, and stir for 6h under this condition to obtain a titanium dioxide sol (sol A);

[0038] Mix 2g ethyl orthosilicate, 0.8g hexadecyltrimethylammonium bromide, 1ml nitric acid and 10ml ethanol, set the reaction temperature at 30°C, stir for 6h under this condition to obtain a silica sol (sol B );

[0039] Mix the above-mentioned A sol and B sol at 40°C for a reaction time of 5 hours to obtain a titanium dioxide-silica mixed solution (mixed solution C);

[0040] Add 1 g of zinc acetate to the titanium dioxide-silicon dioxide mixed solution (mixed solution C), and stir at room temperature for 5 hours to obtain a titanium dioxide-silicon dioxide-metal compound mixed solution (mixed solution D).

[0041] Dissolve 4g of polyacrylamide in 200ml of water, and then slowly add it into t...

Embodiment 2

[0046] 2.1 Catalyst preparation process

[0047] Mix 2g of isopropyl titanate, 0.6g of hexadecyltrimethylammonium bromide, 1ml of concentrated hydrochloric acid and 10ml of distilled water, set the reaction temperature at 0°C, and stir for 10h under this condition to obtain a titanium dioxide sol (sol A) ;

[0048] Mix 7g of ethyl orthosilicate, 1g of sodium dodecylsulfonate, 2ml of concentrated hydrochloric acid and 20ml of ethanol, set the reaction temperature at 60°C, and stir for 10h under this condition to obtain a silica sol (sol B);

[0049] Mix the above-mentioned A sol and B sol at 40°C for a reaction time of 8 hours to obtain a titanium dioxide-silica mixed solution (mixed solution C);

[0050] Add 2g of magnesium acetate to the titanium dioxide-silicon dioxide mixed solution (mixed solution C), and stir at 40°C for 1 hour to obtain a titanium dioxide-silicon dioxide-metal compound mixed solution (mixed solution D). Dissolve 4g of polyvinylpyrrolidone in 160ml of w...

Embodiment 3

[0055] 3.1 Catalyst preparation process

[0056] Mix 5g of n-butyl titanate, 2ml of concentrated hydrochloric acid, 2g of sodium polyacrylate and 30ml of distilled water, set the reaction temperature at 0°C, and stir for 4 hours under this condition to obtain a titanium dioxide sol (sol A);

[0057] Mix 2g of tetraethyl orthosilicate, 1ml of concentrated hydrochloric acid and 10ml of ethanol, set the reaction temperature at 30°C, and stir for 4 hours under this condition to obtain a silica sol (sol B);

[0058] Mix the above-mentioned A sol and B sol at 30°C for a reaction time of 5 hours to obtain a titanium dioxide-silica mixed solution (mixed solution C);

[0059] Add 1.5g of manganese acetate to the titanium dioxide-silica mixed solution (mixed solution C), and stir at 60°C for 5h to obtain a titanium dioxide-silicon dioxide-metal compound mixed solution (mixed solution D).

[0060]Dissolve 4g of sodium polyacrylate in 200ml of water, and then slowly add it into the titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com