Preparation method of composite modified zeolite molecular sieve catalyst

A zeolite molecular sieve and composite modification technology, applied in the field of denitration catalysts, can solve the problems of difficult control of distribution state and large difference in catalyst activity, and achieve the effects of wide temperature window, high catalytic activity and high thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

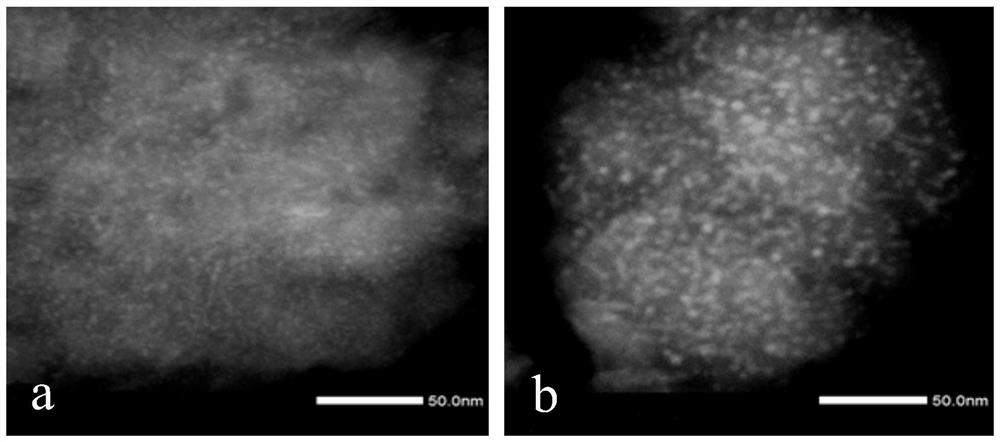

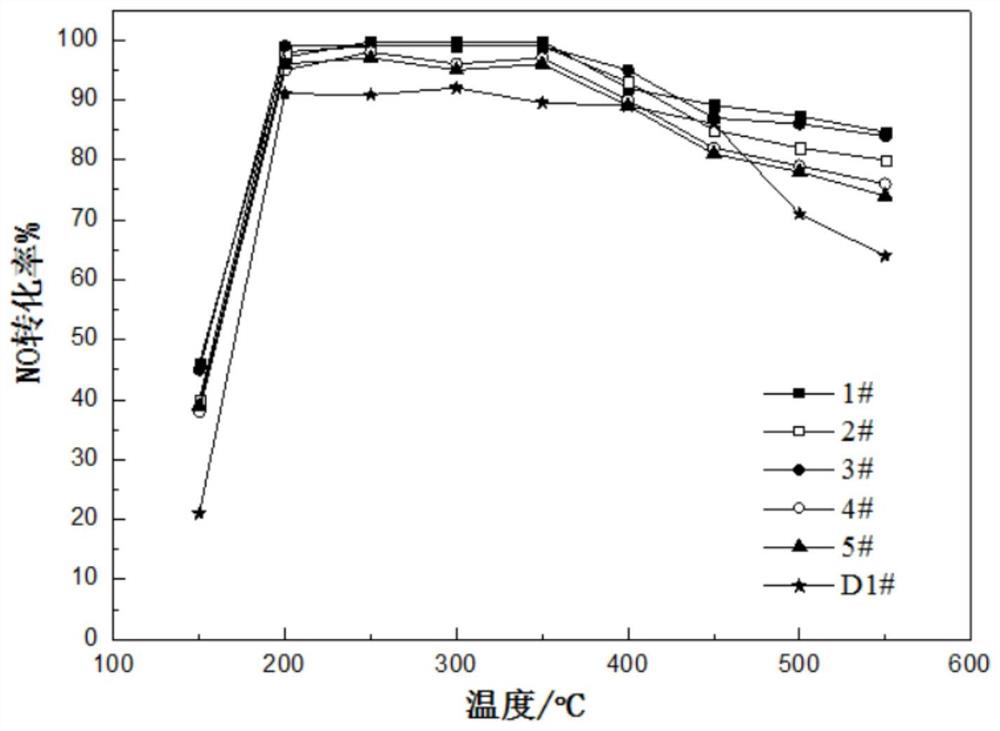

Image

Examples

Embodiment 1

[0066] Put 10 g of SSZ-13 zeolite molecular sieve after dehydration pretreatment into 8M copper nitrate solution, stir at 50° C. for 10 h, and filter the obtained solid. Then put the above solid into 0.8M copper nitrate solution, stir at 50°C for 10h, and filter to obtain the solid. Then put the above solid into 0.08M copper nitrate solution, add 0.2g ferric nitrate and 0.34g cerium nitrate, stir at 50°C for 10h, and filter to obtain solid. The solid was dried and calcined to obtain a composite modified zeolite molecular sieve catalyst, which was designated as sample 1#.

Embodiment 2

[0068] Put 10 g of SSZ-13 zeolite molecular sieve after dehydration and pretreatment into 5M copper acetate solution, stir at 50° C. for 10 h, and filter the obtained solid. Then put the above solid into 0.5M copper acetate solution, stir at 50° C. for 10 h, and filter to obtain the solid. Then put the above solid into 0.05M copper acetate solution, add 0.2g ferric nitrate and 0.34g cerium nitrate, stir at 50°C for 10h, and filter to obtain the solid. The solid was dried and calcined to obtain a composite modified zeolite molecular sieve catalyst, which was designated as sample 2#.

Embodiment 3

[0070] Put 10 g of SSZ-13 zeolite molecular sieve after dehydration and pretreatment into 5M copper acetate solution, stir at 50° C. for 10 h, and filter the obtained solid. Then put the above solid into 0.5M copper acetate solution, stir at 50° C. for 10 h, and filter to obtain the solid. Then put the above solid into 0.05M copper acetate solution, add 0.2g ferric nitrate and 0.28g lanthanum nitrate, stir at 50°C for 10h, and filter to obtain the solid. The solid was dried and calcined to obtain a composite modified zeolite molecular sieve catalyst, which was designated as sample 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com