Diversion tunnel blasting excavation back break and out break controlled construction method

A construction method and technology for diversion tunnels, which are applied in blasting and other directions, can solve the problems of large unit consumption of explosives, large clamping property, poor construction effect, etc., and achieve the effects of improving construction quality, rapid lithology changes, and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

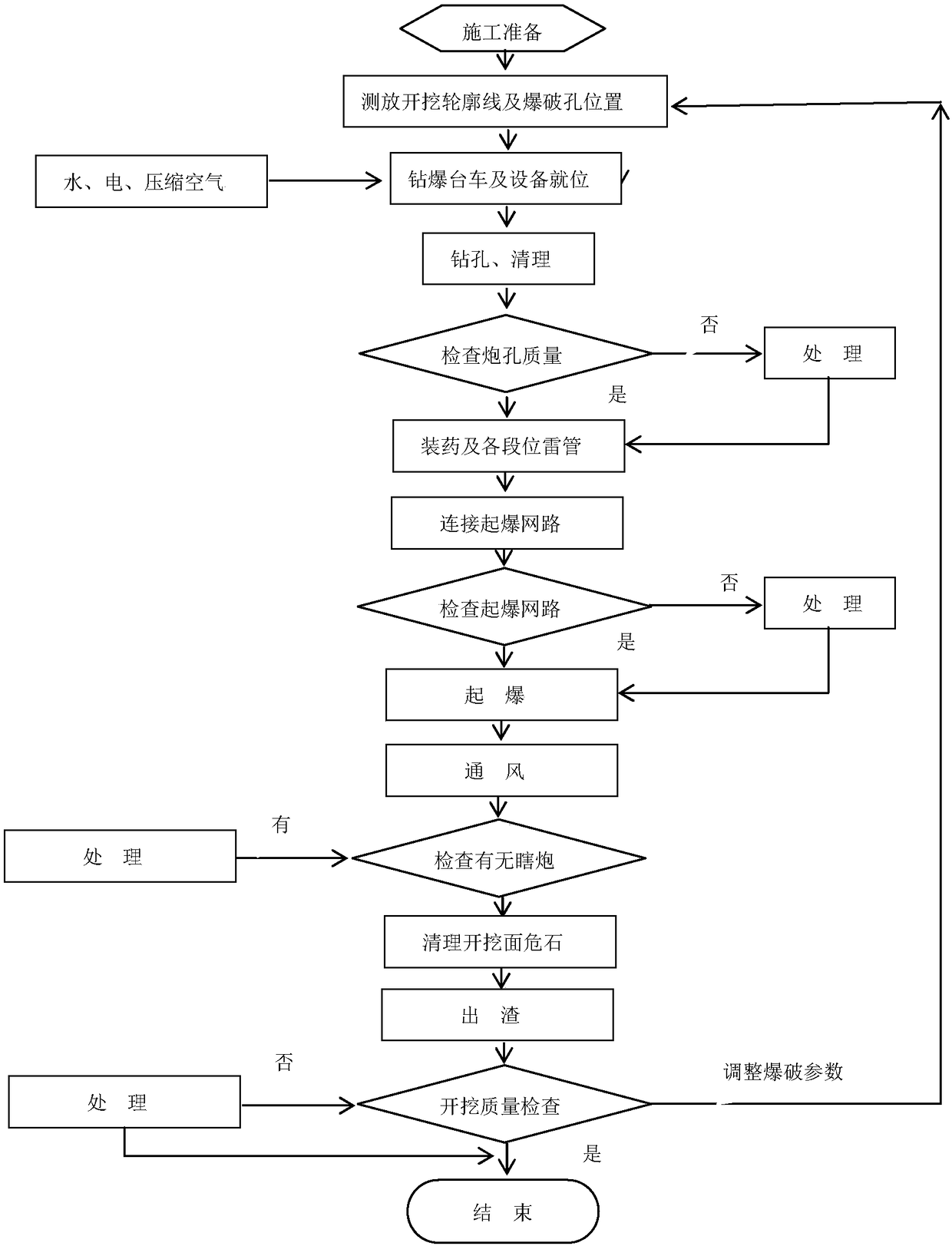

[0032] The construction method for controlling over- and under-excavation of a water diversion tunnel by blasting excavation provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

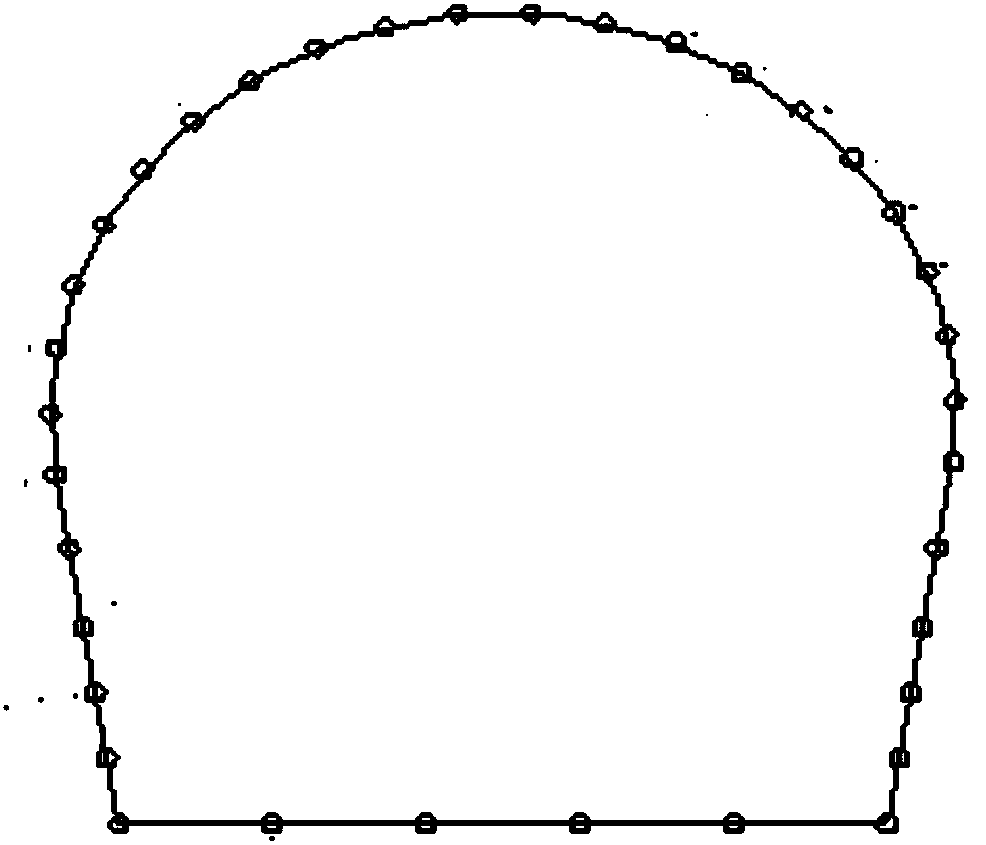

[0033] The main project of a water supply construction bid is a diversion tunnel with a total length of 12256.514m. The tunnel is a pressurized tunnel. The excavation section is a round arch inclined wall. The lithology of the cavern is mainly composed of volcanic breccia, basalt, argillaceous siltstone, argillaceous pebble-bearing sandstone, and tuffaceous lithic sandstone. 55%; Class IV surrounding rocks accounted for 10%; Class V surrounding rocks accounted for 35%. Good results have been obtained by adopting the construction method for controlling over- and under-excavation of blasting excavation of water diversion tunnels provided by the invention to control over- and under-excavation of blasting excavation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com