Super large-scale stope large-diameter, deep-hole and high-stage open stope subsequent backfilling mining method

A filling mining method and ultra-large-scale technology, applied in the direction of filling materials, ground mining, mining equipment, etc., can solve the problems of insufficient mining reserves, tight mining replacement, low resource recovery rate, etc., to improve mining efficiency, mining and cutting engineering The effect of small amount and large amount of ore in the stope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

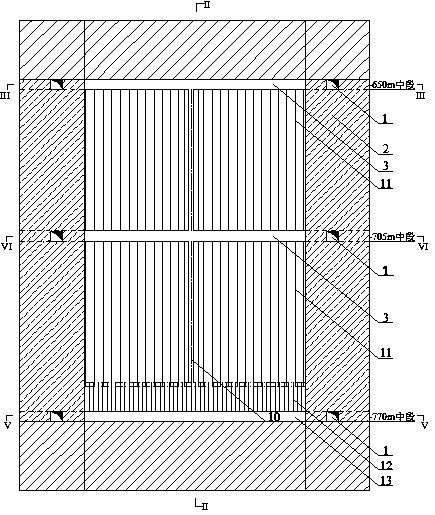

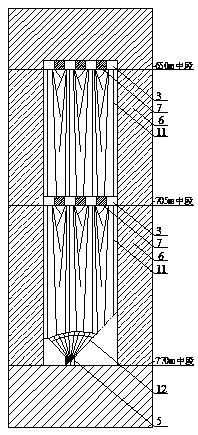

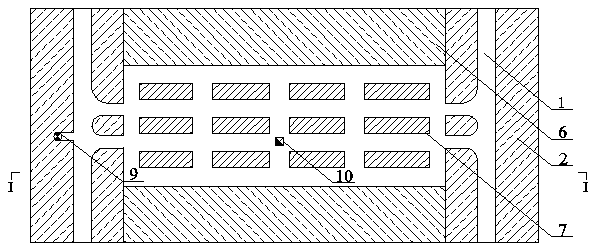

[0021]Embodiment 1: Large-diameter deep hole high-stage open-field subsequent filling mining method in a super-large-scale stope, which includes the following steps: (1), mining scheme: the ore block is arranged vertically to the ore body, and the ore block is divided into ore rooms and ore pillars , the mine room and the ore pillar are arranged at intervals, and the stope is divided into two middle sections by double-middle section continuous mining. The mine structure is arranged in the middle section of -770m, and the rock drilling chambers in the upper middle section and the lower middle section are respectively arranged in the middle section of -705m and -650m. The mine room is 80m long, 30m wide, and 120m high. ; (2) Mining standard: The middle section of -705m and the middle section of -650m are respectively distributed with the middle section of the rock drilling chamber 3, the middle section of the transport level roadway 1, the panel interval column 2, the ore column ...

Embodiment 2

[0022] Embodiment 2: The difference from Embodiment 1 is that the cutting patio in the rock drilling chamber in the middle section of -650m can reach the middle section of -705m, and the height of the cutting patio is 50mm; The cutting patio of the cutting ditch is 50mm high, and the bottom structure of the cutting trench is 15m high.

Embodiment 3

[0023] Embodiment 3: The difference from Example 1 is that the cutting patio in the rock drilling chamber in the middle section of -650m reaches the rock drilling chamber in the middle section of -705m, and the height of the cutting patio is 47mm; the construction in the rock drilling chamber in the middle section of -705m reaches the middle section of -770m The cutting patio of the cutting ditch is 47mm high, and the bottom structure of the cutting trench is 17m high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com