Multielement three-dimensional safety protection method

A safety protection and three-dimensional technology, applied in blasting and other directions, can solve the problems of cumbersome construction, high cost, poor protection effect, etc., and achieve the effect of improving protection effect, improving coverage effect and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

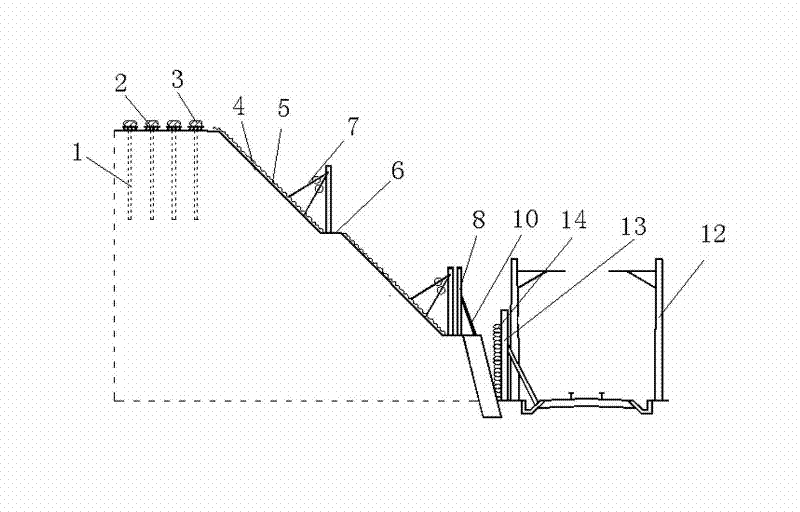

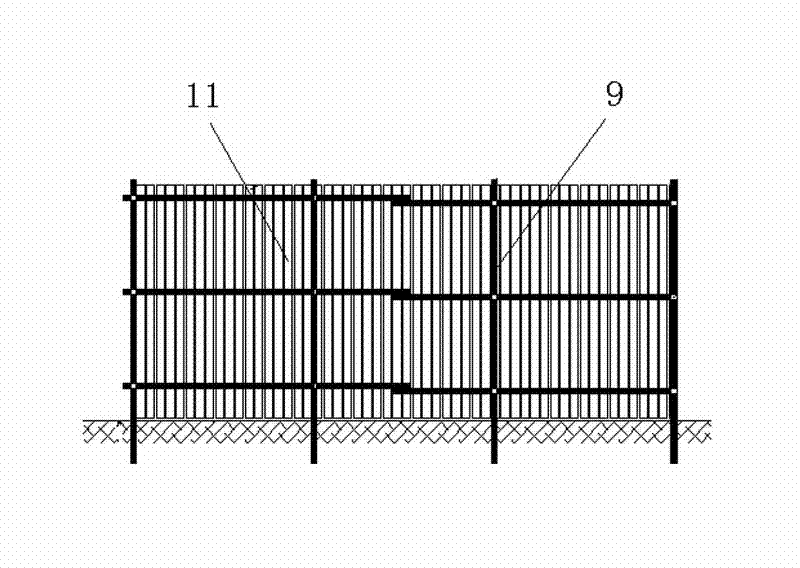

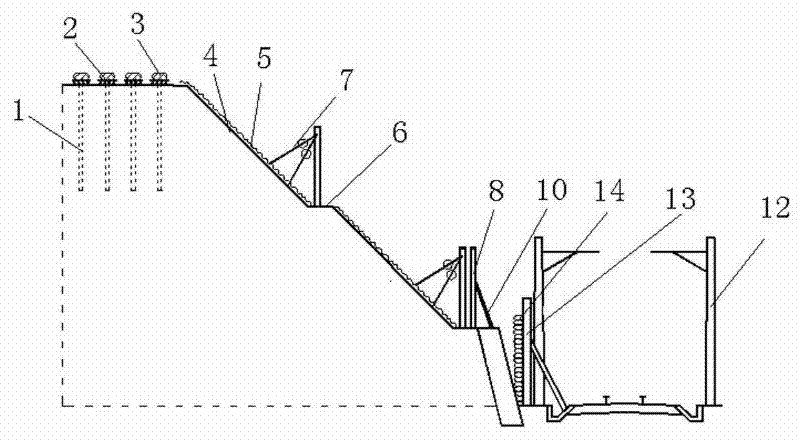

[0011] The multi-dimensional three-dimensional safety protection method adopts the following steps: a. According to the terrain, landform and blasting engineering quantity of the blasting point, survey the cross-sectional view of the blasting point; Thickness, slope height and rock formation direction; c. Each hole 1 is covered with a quilt 2, and a sandbag 3 is sealed on the quilt 2; d. The SNS active flexible protective net 5 is fixed on the slope surface 4, and the slope Platform 6 fixes SNS passive flexible protective net 7; e, the back side of SNS passive flexible protective net 7 is fixed with steel pipe bamboo row frame 8, and steel pipe bamboo row frame 8 comprises horizontal and vertical steel pipe cross connection and vertical steel pipe is buried underground protection layer 9, protection The back side of the layer 9 is fixed with a diagonal brace 10, and the front side of the protective layer 9 is fixed with a bamboo frame plate 11. The front side of the existing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com