Stone drift driving method adopting technologies of water cutting and cut blasting

A technology for grooving and rock roadway, applied in the field of roadway excavation construction, can solve the problems of poor cutting quality and cutting effect, failing to meet the technical standards for medium and deep holes, limiting the speed of roadway excavation, etc., to ensure blasting construction. quality, improve blasting speed, and ensure the effect of construction level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

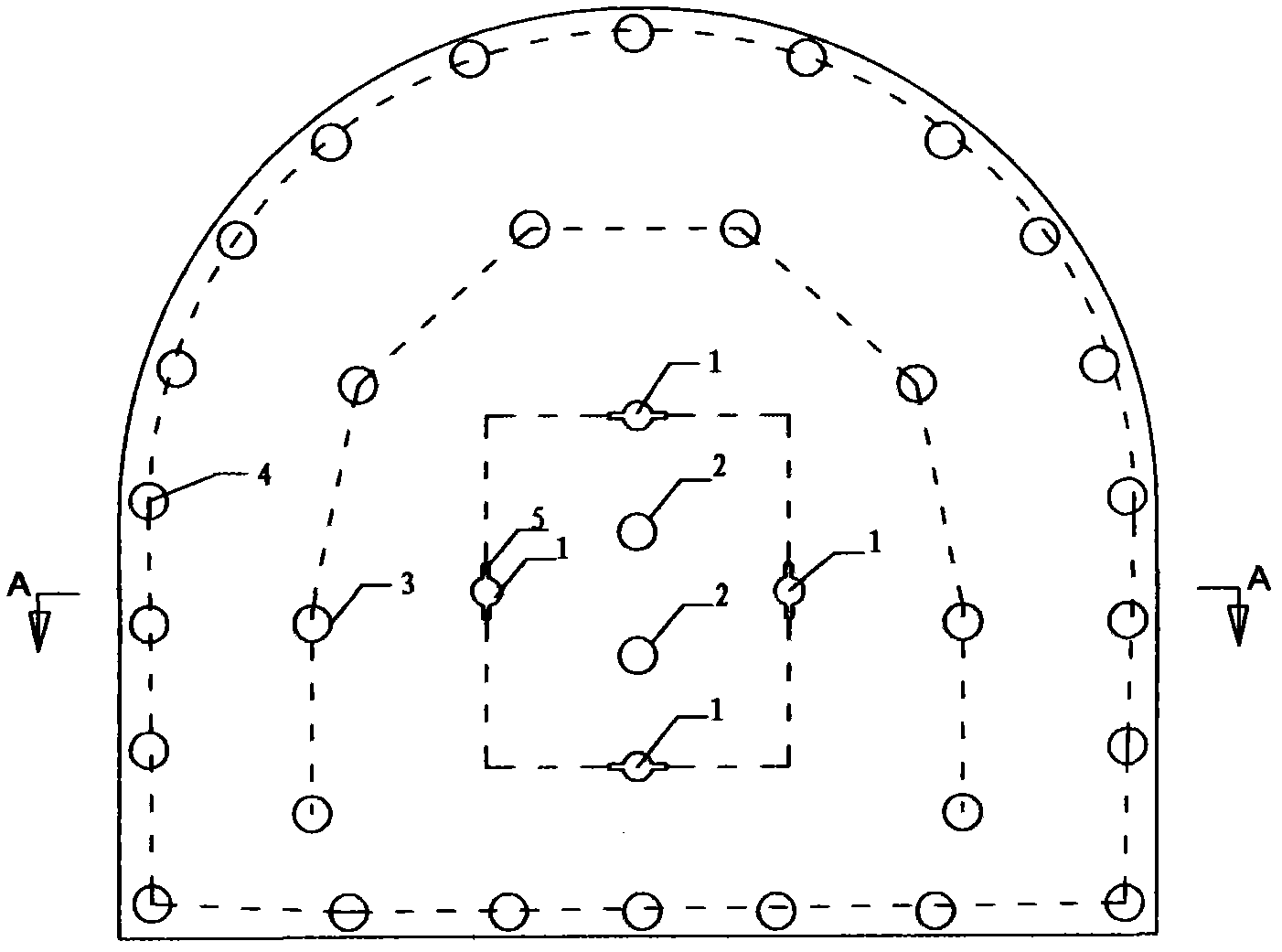

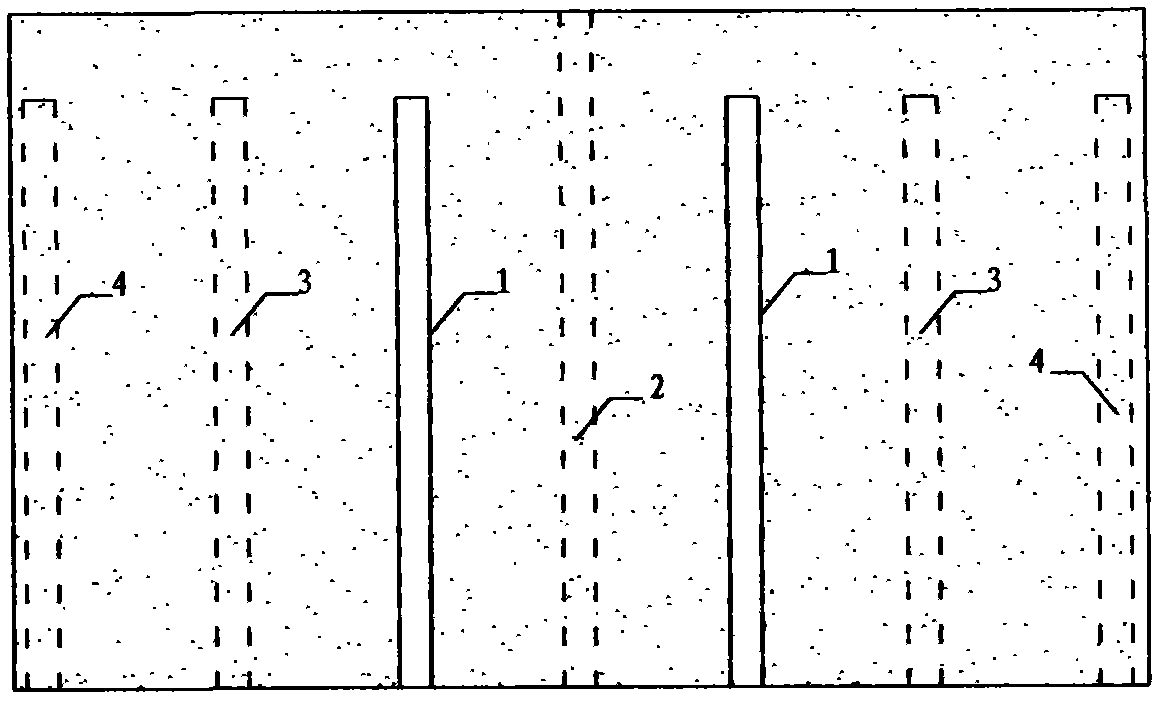

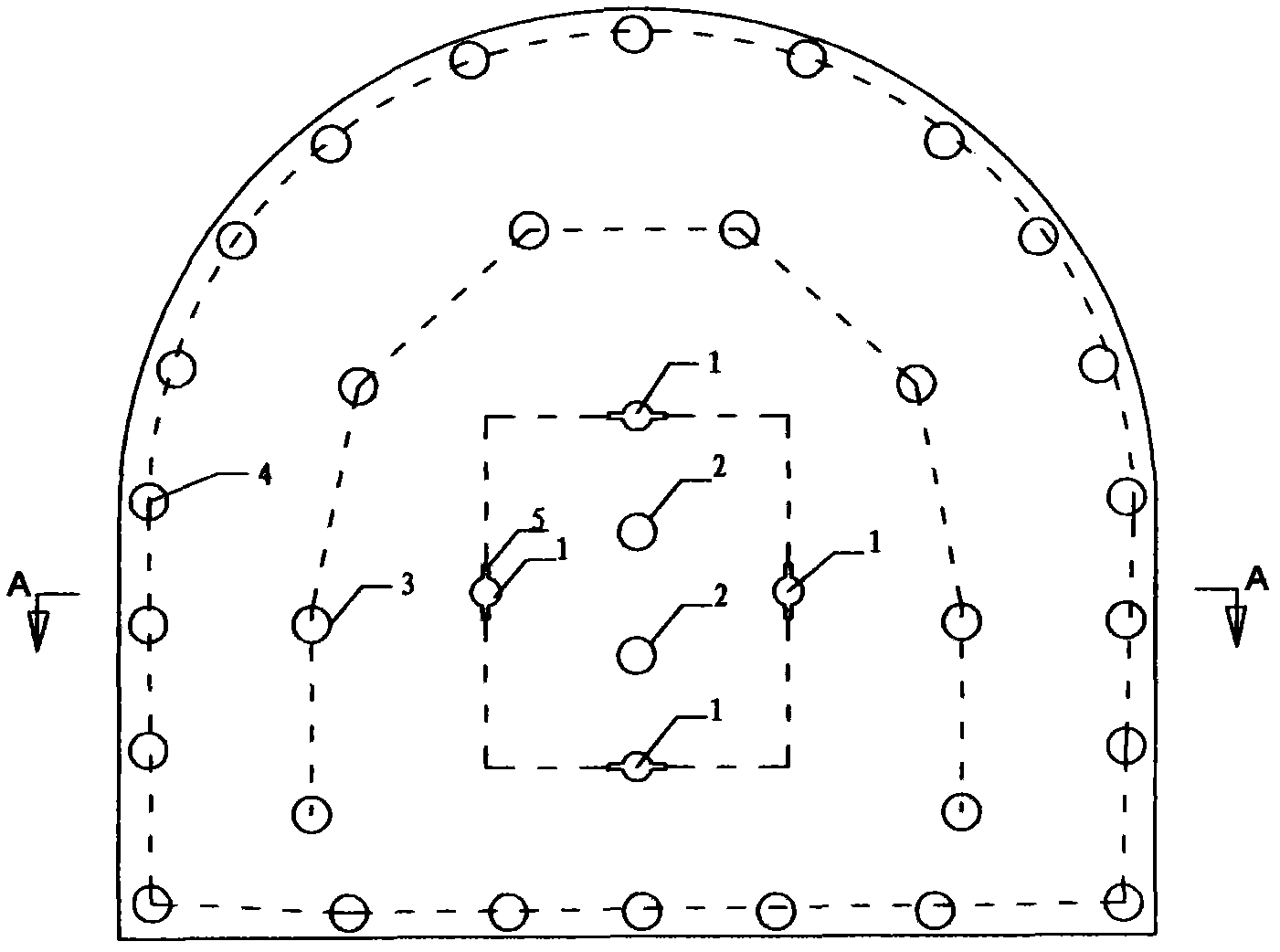

[0019] Attached below figure 1 , figure 2 The specific embodiment of the present invention is described further:

[0020] The rock roadway excavation method using water cutting and grooving blasting technology described in the present invention takes four grooving blastholes as an example, and the specific steps include:

[0021] Step 1 Arrange four blastholes 1 in the center of the roadway section, the spatial positions of the four blastholes 1 are distributed in a circular shape, and the center distance of the blastholes is 800-1200mm; two center holes 2 are arranged in the central area surrounded by the blastholes 1 , and arrange caving holes 3 and peripheral holes 4 in other parts of the roadway section according to conventional methods.

[0022] Among them, the diameter of the blast hole 1, the center hole 2, the collapse hole 3 and the peripheral hole 4 is 30-45 mm, the depth of the blast hole 1, the collapse hole 3 and the peripheral hole 4 is 1500-2500 mm, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com