Heating defoaming device

A defoaming device and heating device technology, applied in the field of defoaming devices, can solve the problems of lye pollution, increase production cost, affect degreasing production, etc., achieve high steam utilization rate, avoid mutual influence, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

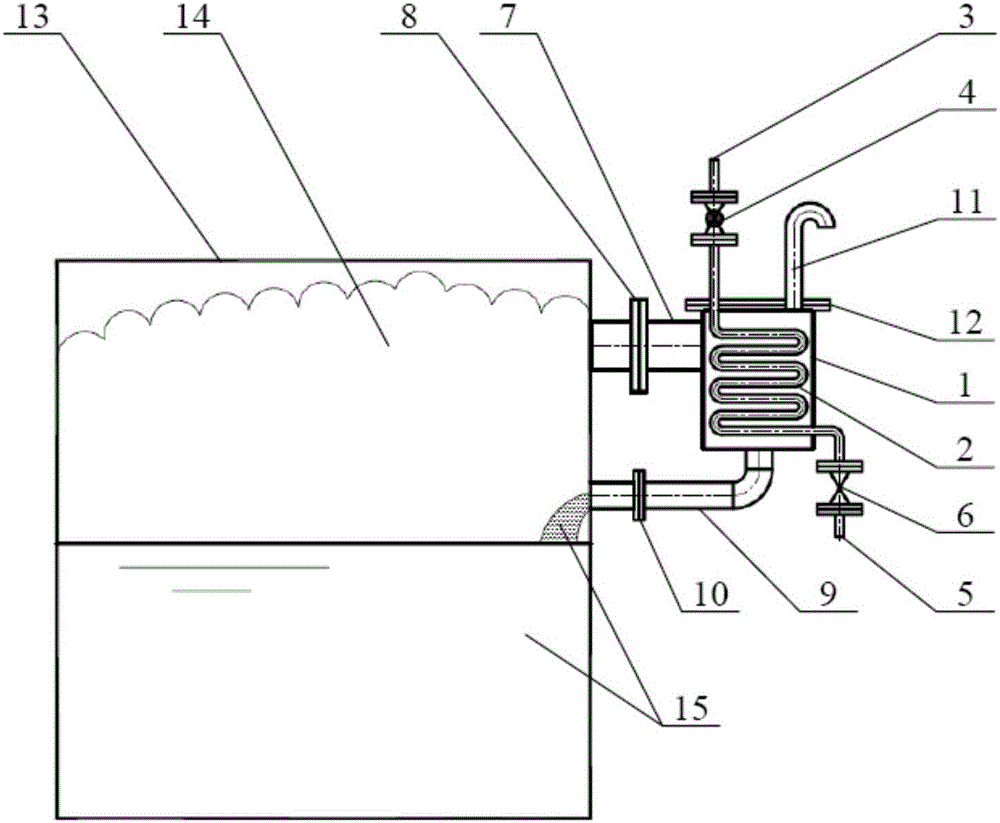

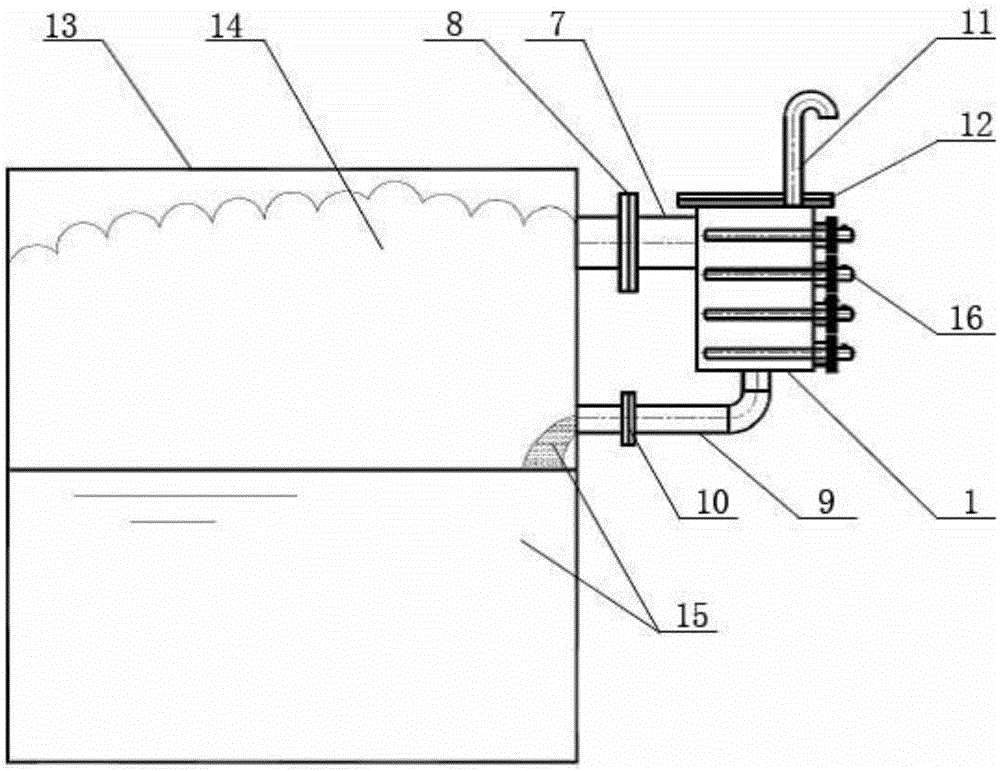

[0024] Such as figure 1 As shown, the heating and defoaming device of the present invention is installed on the lye circulation tank 13. The heating and defoaming device includes a defoaming box 1 and a heating device arranged in the defoaming box 1 .

[0025] The heating device in this embodiment is preferably a steam heating coil 2 . The defoaming box 1 is provided with a plurality of foam inlet pipes 7, and the foam inlet pipes 7 are connected with the lye circulation tank 13 through the foam inlet 8. One end of the steam heating coil 2 is a steam inlet 3, and the steam inlet 3 is provided with a regulating valve 4. The other end of the steam heating coil 2 is a condensed water outlet 5, and the condensed water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com