Treatment method of complicated zinc-rich leaded material

A treatment method and zinc-rich technology, applied in the direction of improving process efficiency, can solve the problems of difficult treatment, easy formation of furnace junctions, and ineffective recovery of zinc and lead, and achieve easy separation, improved adaptability, and good feasibility. and economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

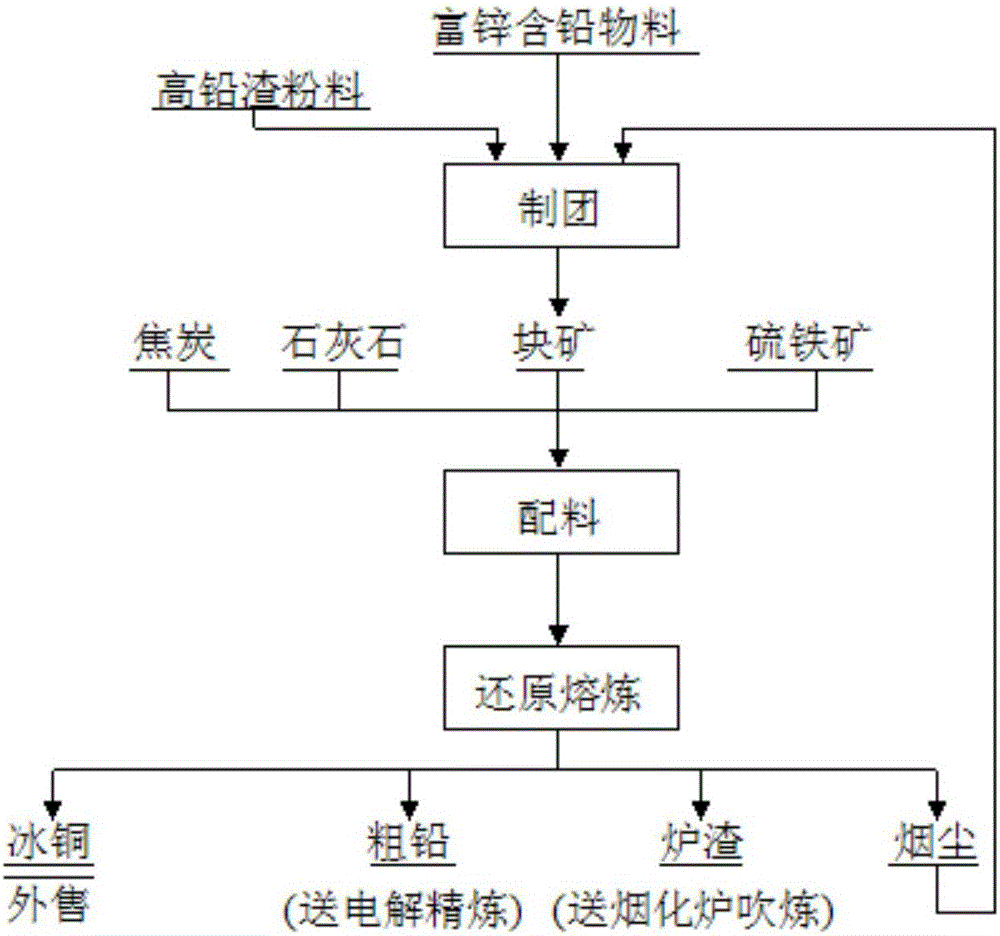

[0022] refer to figure 1 As shown, it is a flow chart of the method for processing zinc-rich and lead-containing materials according to the embodiment of the present invention.

[0023] Step 1: Get zinc-rich and lead-containing materials (the main components and their weight percentages are: Zn15.6%, Pb9.8%, Fe5.3%, Ag32.6g / t, SiO26.4%, Cu0.5%, CaO3.4%, S15.8%), high lead slag powder (the main components and their weight percentages are: Pb44.8%, Zn5.5%, FeO10.3%, Ag348g / t, SiO27.6%, Cu0.9%, CaO5.2%), soot (the main components and their weight percentages are: Pb45.7%, Zn7.9%, Ag39g / t) are mixed together to form a mixture, and water is added to the mixture for stirring, and the The weight percentages of zinc-rich and lead-containing material, high-lead slag powder and soot in the mixture are respectively 45%, 50% and 5%, and the moisture content of the mixture is controlled at 8%. Then send it into the brick making machine to make a lump to form a lump ore, dry it naturally ...

Embodiment 2

[0029] refer to figure 1 As shown, it is a flow chart of the method for processing zinc-rich and lead-containing materials according to the embodiment of the present invention.

[0030] Step 1: get zinc-rich and lead-containing materials (the main components and their weight percentages are: Zn17.2%, Pb13.4%, Fe6.2%, Ag35.3g / t, SiO 2 4.2%, Cu0.9%, CaO5.2%, S14.9%), high lead slag powder (the main components and their weight percentages are: Pb43.2%, Zn4.9%, FeO8.9%, Ag334g / t, SiO 2 6.6%, Cu0.5%, CaO3.9%), soot (the main components and their weight percentages are: Pb47.4.%, Zn9.3%, Ag47g / t) are mixed together to form a mixture, and water is added to the mixture for Stirring, the weight percentages of zinc-rich and lead-containing materials, high-lead slag powder and soot in the mixture are respectively 40%, 55%, and 5%, and the moisture content of the mixture is controlled at 10%; It is formed into a block ore, and it is naturally dried in a ventilated place for 18 hours, ...

Embodiment 3

[0036] refer to figure 1 As shown, it is a flow chart of the method for processing zinc-rich and lead-containing materials according to the embodiment of the present invention.

[0037] Step 1: get zinc-rich and lead-containing materials (main components and percentages by weight thereof are: Zn16.3%, Pb11.8%, Fe5.7%, Ag34.1g / t, SiO 2 5.3%, Cu0.7%, CaO4.3%, S16.9%), high lead slag powder (the main components and their weight percentages are: Pb46.1%, Zn6.5%, FeO12.3%, Ag358g / t, SiO 2 9.1%, Cu1.5%, CaO6.1%), soot (the main components and their weight percentages are: Pb42.3%, Zn6.1%, Ag32g / t) are mixed together to form a mixture, and water is added to the mixture for stirring The weight percentages of zinc-rich and lead-containing materials, high-lead slag powder and soot in the mixture are respectively 60%, 30%, and 10%, and the moisture content of the mixture is controlled at 12%, and then sent into the brick making machine to make Form lumps into lumps, dry naturally for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com