Multi-station rotary disc type machine for automatically installing cell into box

A turntable, multi-station technology, which is applied in battery assembly machines, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve problems such as lack of real-time detection links, long waiting time for materials, and reduced production stability, etc., to achieve Good variety of box packing, improve box packing quality, and ensure a high degree of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

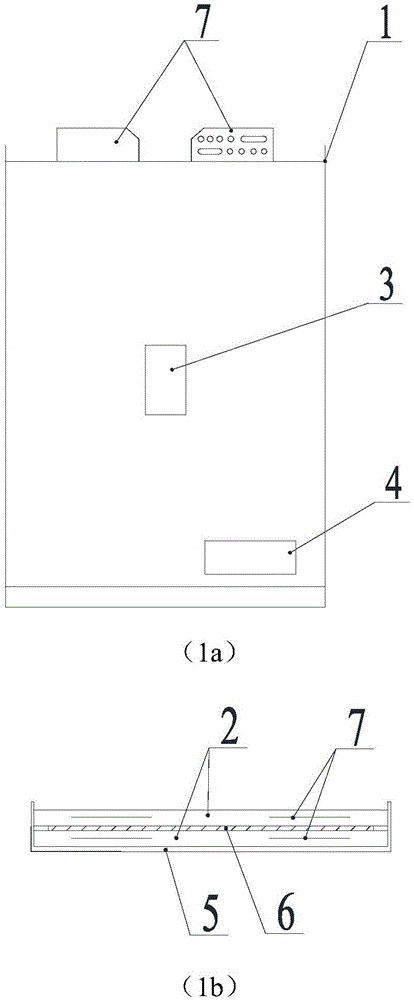

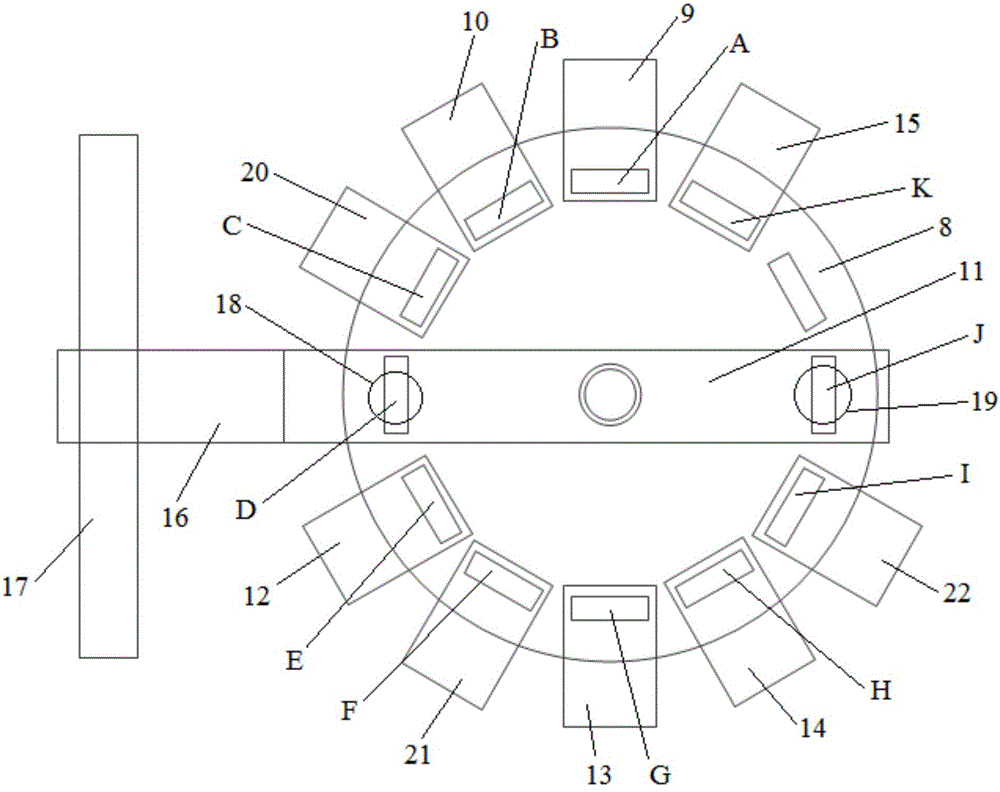

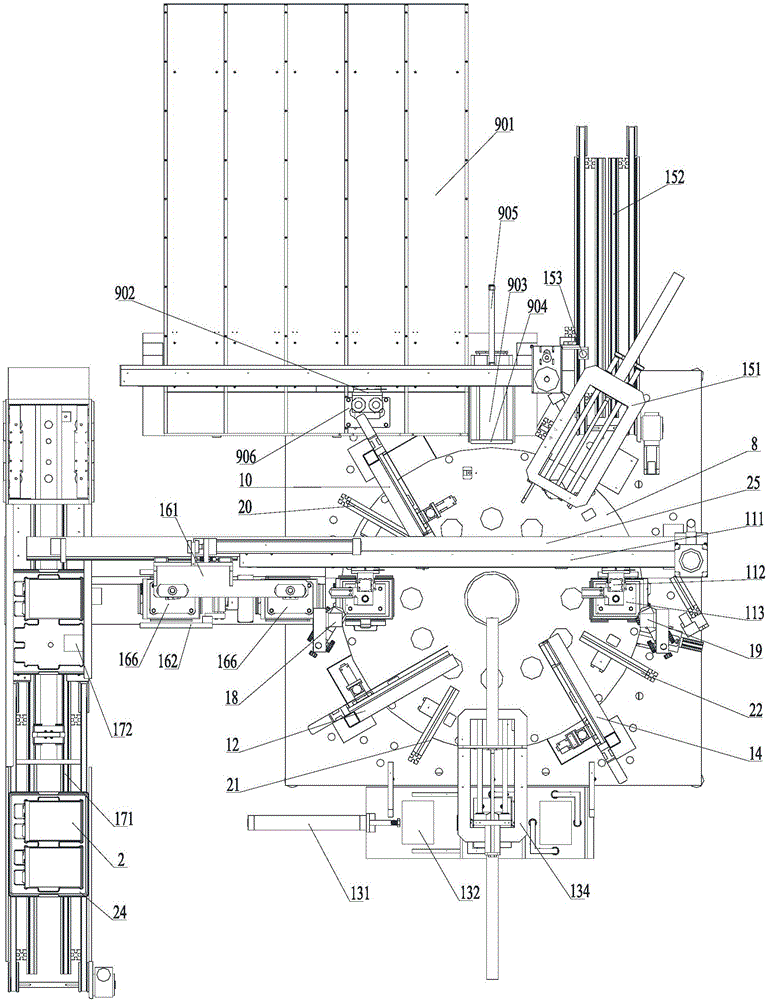

[0047] Such as figure 2 and image 3 As shown, a multi-station turntable type battery automatic box-packing machine includes a working turntable 8, on which 11 stations are arranged along the circumference, and the 11 stations are respectively: cooling plate feeding station A, Cooling plate gluing station B, cooling plate blowing station C, first cell loading station D, cell gluing station E, cell blowing station F, heat insulation pad feeding station G, heat insulation Mat gluing station H, insulation pad blowing station I, second cell loading station J and finished product blanki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com